Understanding Valve Fittings: Key Trends and Innovations Driving Industry Growth in 2023

In 2023, the valve fittings market is poised for significant growth, driven by key trends and innovations that enhance efficiency and reliability across various industries. According to a recent report by MarketsandMarkets, the global valve fittings market is expected to reach USD 80 billion by 2026, growing at a CAGR of 4.5% from 2021. This increase is primarily fueled by advancements in smart technologies and automation, which optimize operations in sectors such as oil and gas, water and wastewater management, and food and beverage. Moreover, sustainability initiatives are pushing manufacturers to innovate eco-friendly valve fittings that minimize environmental impact while delivering superior performance. As industries adapt to these transformative trends, understanding the intricacies of valve fittings—ranging from materials science to regulatory compliance—becomes paramount for stakeholders aiming to stay competitive in this evolving landscape.

Exploring the Basics: What Are Valve Fittings and Their Applications?

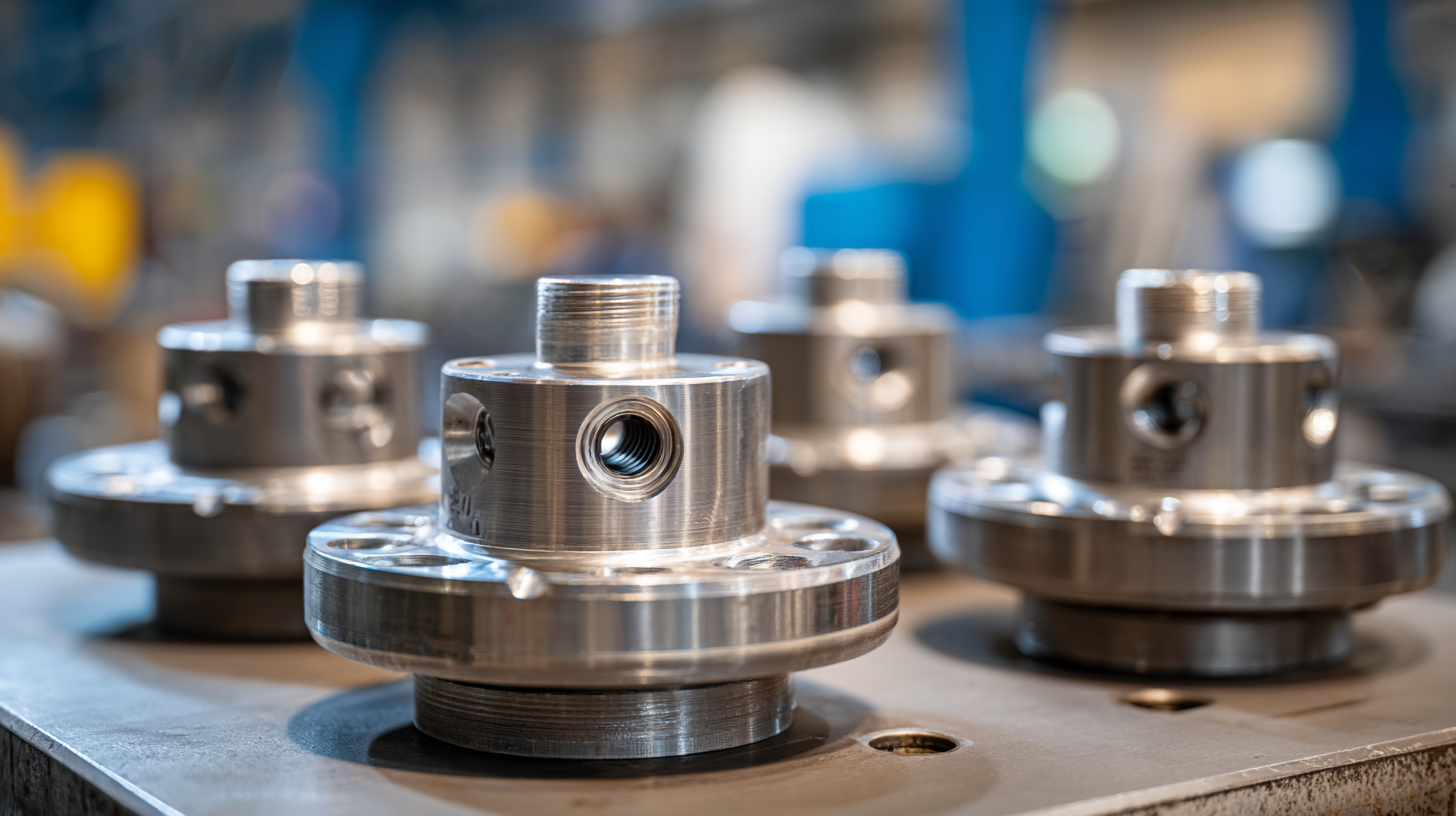

Valve fittings are essential components in various industries, serving as critical junctions for controlling fluid flow within piping systems. These fittings are designed to connect pipes, tubes, and hoses, thereby simplifying maintenance and enabling the safe transport of various substances. According to a report by MarketsandMarkets, the global valve fittings market is projected to reach $18.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8%. This growth underscores the increasing demand for efficient fluid management solutions across sectors such as oil and gas, water and wastewater treatment, and chemical manufacturing.

Valve fittings are essential components in various industries, serving as critical junctions for controlling fluid flow within piping systems. These fittings are designed to connect pipes, tubes, and hoses, thereby simplifying maintenance and enabling the safe transport of various substances. According to a report by MarketsandMarkets, the global valve fittings market is projected to reach $18.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8%. This growth underscores the increasing demand for efficient fluid management solutions across sectors such as oil and gas, water and wastewater treatment, and chemical manufacturing.

The applications of valve fittings vary widely, from simple on/off controls to complex systems regulating pressure and flow rates. In the industrial sector, for instance, valve fittings help ensure the safe operation of systems by allowing for quick isolation during maintenance tasks. Furthermore, innovations in materials—such as high-strength plastics and corrosion-resistant alloys—are expanding the use of valve fittings in extreme environments. A recent research report highlights a significant rise in the adoption of smart valve fittings that integrate IoT technology, enabling remote monitoring and predictive maintenance. This trend is transforming traditional practices, enhancing operational efficiency, and fortifying safety measures across the industry.

Identifying Key Trends in Valve Fittings: Innovations Shaping 2023

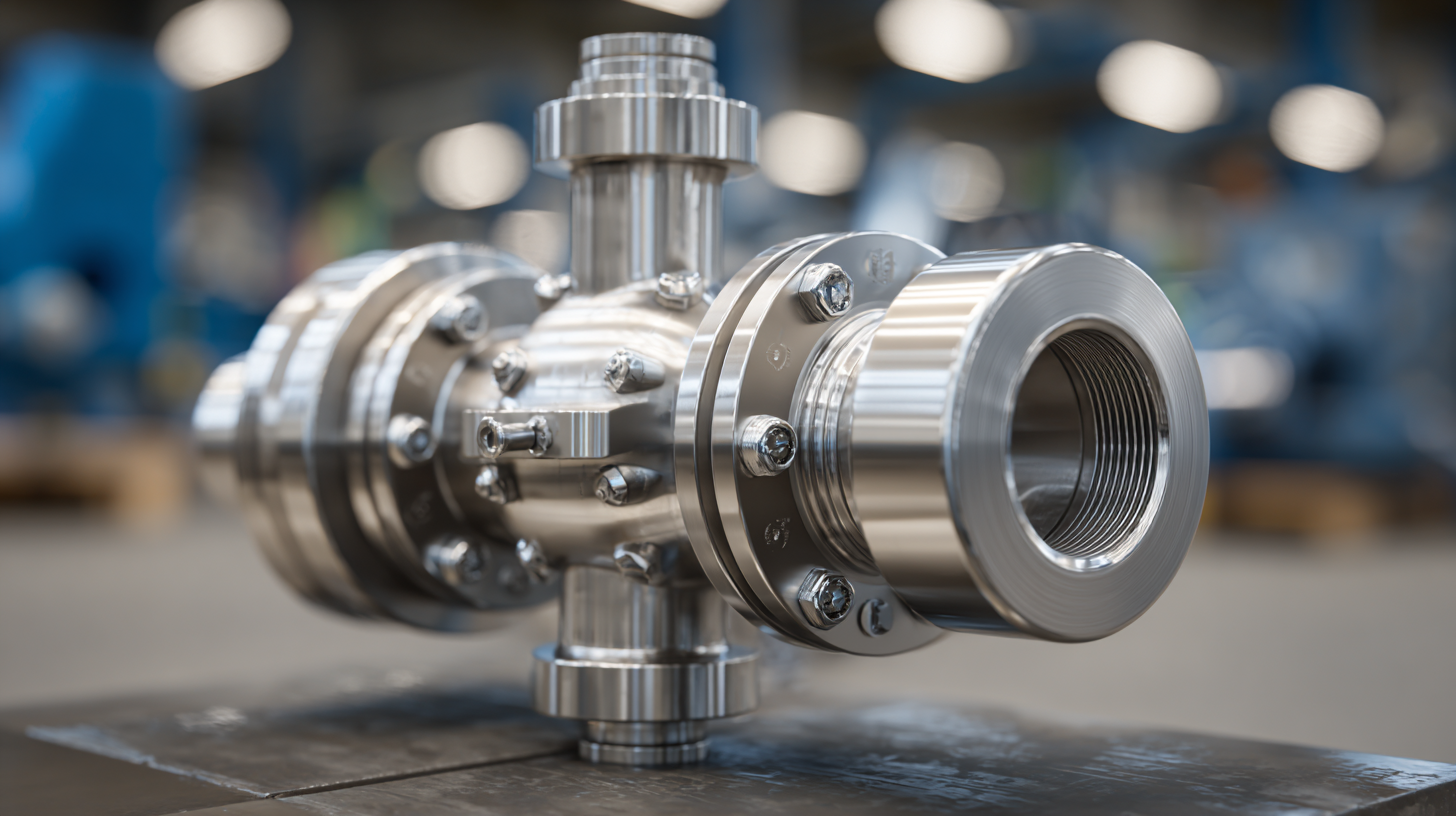

In 2023, the valve fittings industry is seeing significant innovations driven by the need for enhanced functionality and safety in various applications. Key trends include the development of advanced materials that improve durability and resistance to corrosion, thereby extending the lifespan of valve fittings. This development is particularly crucial in harsh environments where reliability is paramount. Additionally, the trend towards modular design is allowing for greater customization, enabling users to select components that are best suited to their specific operational needs.

Furthermore, the integration of smart technology into valve fittings is revolutionizing how they are monitored and controlled. Innovations such as IoT-enabled fittings allow for real-time data collection on flow rates, pressure levels, and potential leaks, ensuring optimal performance and maintenance scheduling. This technological advancement not only enhances operational efficiency but also significantly reduces downtime and associated costs. Overall, these innovations are shaping the valve fittings landscape, driving growth and providing end-users with more efficient and reliable solutions.

Key Innovations in Valve Fittings Market - 2023

How Digital Technology is Revolutionizing Valve Fitting Design and Production

The integration of digital technology in valve fitting design and production is transforming the industry in 2023. Advanced manufacturing techniques, including autonomous microfactories, are playing a pivotal role in this revolution. These compact manufacturing cells, designed to function with minimal human intervention, address critical labor shortages while ensuring precision and efficiency in production processes. By leveraging these technologies, manufacturers can streamline operations and adapt swiftly to market demands, leading to enhanced customization and reduced lead times.

Moreover, the rise of additive manufacturing, notably through 3D printing, is significantly impacting the valve fittings sector. This technology enables rapid prototyping and the production of complex designs that were previously challenging or impossible to achieve. The ability to quickly iterate on designs allows engineers to innovate more freely and efficiently, resulting in products that better meet the needs of diverse applications. As digital solutions continue to evolve, the valve fittings industry stands poised for unprecedented growth driven by these technological advancements.

Sustainability in Valve Fittings: Eco-Friendly Innovations Driving Market Growth

The concept of sustainability is gaining traction across various industries, including valve fittings. Eco-friendly innovations are revolutionizing the market, promoting the reduction of environmental impact while enhancing performance. In 2023, manufacturers are increasingly focusing on developing sustainable materials and processes, which not only comply with global environmental standards but also appeal to eco-conscious consumers. Innovations such as reusable fittings and designs that minimize waste are at the forefront of this shift.

Tips: To align your operations with sustainable practices, consider investing in research to identify eco-friendly materials suitable for your valve fittings. Implementing a life cycle assessment can help highlight potential areas for improvement and sustainability. Engaging with suppliers who prioritize sustainability will also enhance your product offerings while contributing to a greener future.

As the demand for sustainable solutions rises, the valve fittings industry is expected to experience significant growth. Companies that embrace these innovations are not only poised to lead in market share but also contribute to a broader movement towards a sustainable economy. By integrating green practices into your business model, you can enhance brand loyalty and drive customer satisfaction in an increasingly competitive market.

Navigating Challenges: Addressing Common Issues in Valve Fitting Selection and Use

Selecting the right valve fittings is a critical task that can significantly influence the performance and reliability of any fluid handling system. Common challenges faced during the selection process include compatibility of materials, pressure ratings, and potential leakage issues. Users must carefully assess the application requirements while paying attention to industry standards to avoid costly errors. The integration of advanced materials, such as composites or high-performance alloys, can often mitigate corrosion and extend the lifespan of fittings, making them a crucial component in industries like oil and gas, water treatment, and pharmaceuticals.

Moreover, the installation and maintenance of valve fittings present additional hurdles that can hinder operational efficiency. Incorrect installation can lead to functional failures, making it essential to follow best practices and manufacturer guidelines. Utilizing technologies such as digital monitoring is becoming increasingly popular to address these issues. These tools not only facilitate real-time monitoring of system performance but also aid in early detection of malfunctions, thus enhancing the overall reliability of valve fittings in various applications. Ultimately, a comprehensive understanding of both the selection process and ongoing management strategies is vital for navigating the complexities associated with valve fitting use.

Related Posts

-

How to Choose the Right Fittings and Valves for Your Industrial Needs

-

Top Strategies for Enhancing Performance with Fittings Valves

-

Essential Guide to Choosing the Right Valve Fittings for Optimal Performance

-

How to Choose the Right Sanitary Pipe Fittings for Your Plumbing Needs

-

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

-

Ultimate Sanitary Connectors Checklist for Ensuring Compliance and Efficiency