The Ultimate Guide to Choosing the Best Sanitary Tubing for Your Business Needs

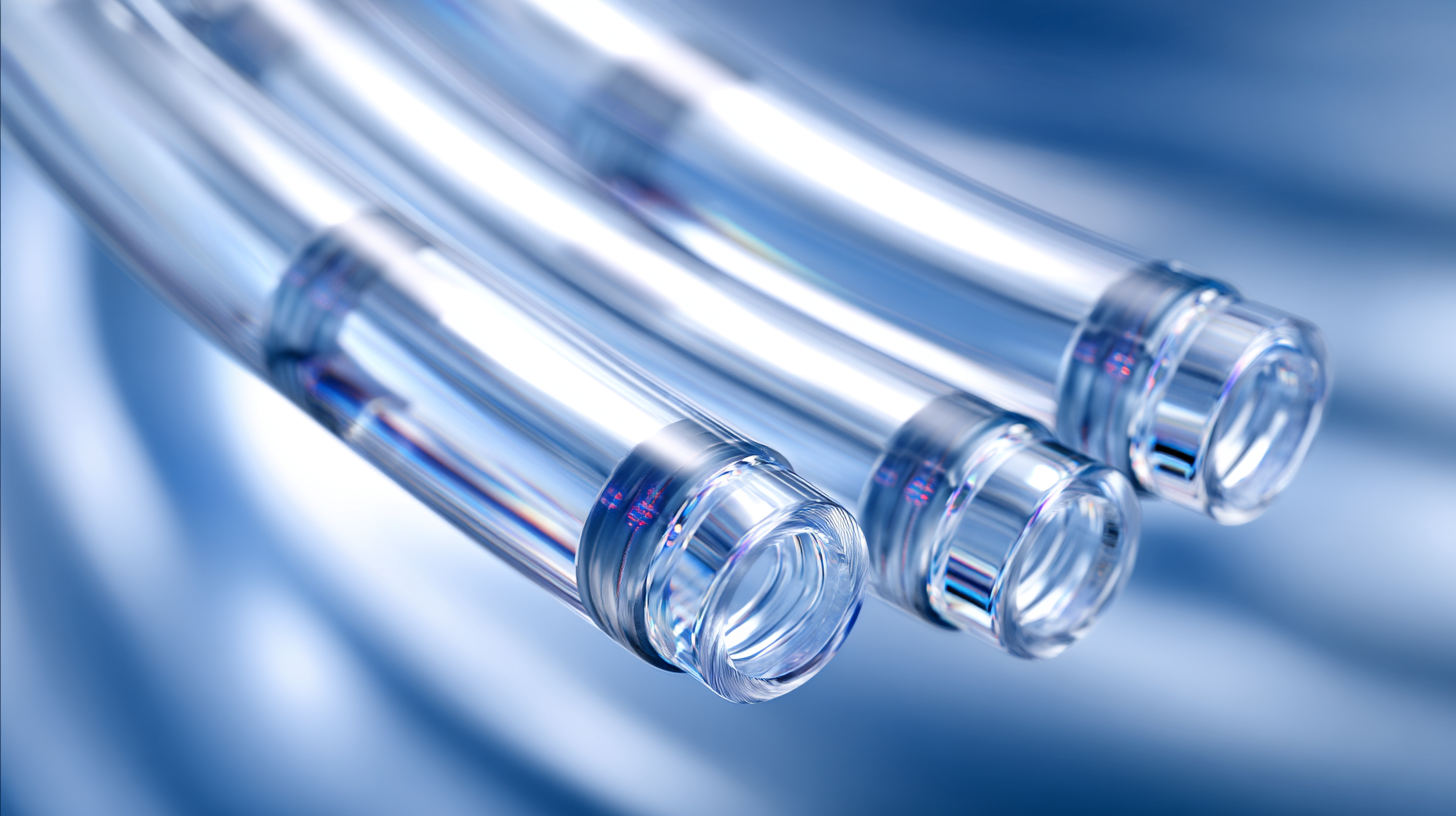

In the ever-evolving landscape of industries that demand hygiene and precision, choosing the right sanitary tubing is crucial for ensuring product integrity and operational efficiency. This definitive guide delves into the intricacies of selecting the best sanitary tubing tailored to your unique business needs. From understanding the various materials available to examining industry standards and regulations, we aim to provide you with essential tips that simplify the decision-making process.

Whether you are involved in food processing, pharmaceuticals, or biotechnology, we will highlight key factors to consider, including compatibility with current systems, ease of cleaning, and durability. By the end of this guide, you will be equipped with the knowledge to make informed decisions, enabling your operations to thrive while maintaining the highest standards of safety and hygiene in your processes.

Key Factors to Consider When Selecting Sanitary Tubing for Your Operations

When selecting sanitary tubing for your operations, several key factors must be taken into account to ensure optimal performance and compliance with industry standards. One of the primary considerations is the material of the tubing. A report by the International Society for Pharmaceutical Engineering (ISPE) highlights that stainless steel remains the most popular choice due to its durability, resistance to corrosion, and ability to withstand high temperatures. In contrast, the growing adoption of thermoplastic materials is attributed to their flexibility and lower cost, making them suitable for certain applications, especially in smaller operations.

Another critical aspect to evaluate is the tubing's size and dimensions, which directly affect flow rates and system efficiency. According to a study published by the Fluid Handling Industry, tubing sizes should be chosen based on thorough calculations of the system’s requirements, taking into consideration factors such as pressure drop and flow velocity. Moreover, adherence to sanitary standards, such as those set by the FDA and 3A Sanitary Standards, is essential for industries like food and pharmaceuticals. By ensuring your sanitary tubing meets these regulations, you help maintain the integrity of your processes and the safety of your final products.

Understanding Different Materials Used in Sanitary Tubing and Their Applications

When selecting sanitary tubing for your business, understanding the materials available is crucial to ensure optimal performance and compliance. Stainless steel is widely recognized for its durability and resistance to corrosion, making it the preferred choice in industries such as food processing and pharmaceuticals. According to a report by MarketsandMarkets, the stainless steel tubing market is projected to reach $5.2 billion by 2026, driven by its strength and sanitary properties. The material’s ability to withstand high temperatures and harsh cleaning regimes further solidifies its position in the market.

Another popular option is hygienic plastic tubing, which is gaining traction due to its lightweight nature and ease of installation. Materials like polyethylene and polypropylene are often used for their excellent chemical resistance and flexibility. A recent study published in the Journal of Food Engineering highlighted that the use of plastic sanitary tubing has increased by 15% in the last five years, particularly in applications where weight savings are critical, such as in beverage systems. Ultimately, the choice of material will greatly influence not only the efficiency of operations but also the long-term cost-effectiveness for businesses across various sectors.

The Ultimate Guide to Choosing the Best Sanitary Tubing

Evaluating the Importance of Compliance Standards in Sanitary Tubing Selection

When selecting sanitary tubing for your business, compliance with industry standards is crucial. These standards ensure that the materials used in manufacturing the tubing are suitable for maintaining product integrity and safety. For sectors such as pharmaceuticals and food processing, even minor lapses in compliance can lead to contamination, ultimately jeopardizing consumer safety and brand reputation. Therefore, understanding the relevant regulations, such as those set forth by the FDA or NSF, can guide businesses in making informed choices.

Moreover, compliance standards often dictate not only the materials used but also the manufacturing processes involved. Tubing that adheres to these stringent guidelines typically undergoes rigorous testing and quality assurance. This means businesses can have confidence in the durability and reliability of the product. Additionally, failing to comply with these standards can result in costly recalls and legal liabilities. By prioritizing compliance in sanitary tubing selection, companies can protect their operations and foster trust with clients and customers, ensuring long-term success in their industries.

The Ultimate Guide to Choosing the Best Sanitary Tubing for Your Business Needs - Evaluating the Importance of Compliance Standards in Sanitary Tubing Selection

| Material | Compliance Standards | Typical Applications | Inner Diameter (ID) | Temperature Range | Pressure Rating |

|---|---|---|---|---|---|

| Silicone | FDA, USP Class VI | Pharmaceuticals, Food & Beverage | 1/4" to 6" | -60°F to 500°F | Up to 100 psi |

| Stainless Steel | 3A, ASTM | Food Processing, Biotechnology | 1/2" to 8" | -320°F to 1500°F | Up to 3000 psi |

| Polyethylene (PE) | FDA, NSF | Water Treatment, Food & Beverage | 1/4" to 4" | 0°F to 120°F | Up to 150 psi |

| TPE (Thermoplastic Elastomer) | FDA, ISO 13485 | Medical Devices, Pharmaceutical | 1/8" to 2" | -40°F to 194°F | Up to 60 psi |

Comparing Costs vs. Quality: How to Make the Right Investment in Sanitary Tubing

When selecting sanitary tubing for your business, the balance between cost and quality is crucial. Recent reports from the International Society for Pharmaceutical Engineering (ISPE) suggest that companies can experience up to a 30% drop in operational efficiency due to inadequate tubing choices. This highlights the need for investing wisely in high-quality materials that ensure compliance with regulations and safety standards. Many businesses may initially lean towards lower-cost options, but the long-term costs associated with product recalls, increased maintenance, and potential health risks can far outweigh initial savings.

According to a market analysis by Grand View Research, the global sanitary tubing market is expected to reach $5.4 billion by 2027, driven by the growing demand for hygienic processing in industries such as pharmaceuticals and food & beverage. Investing in premium sanitary tubing made from high-quality materials not only minimizes risk but also enhances the overall reliability of production processes. For businesses, making the right investment decision involves considering the total cost of ownership, which includes not just the purchase price but also factors like durability, regulatory compliance, and potential downtime due to tubing failure. The right choice of sanitary tubing can indeed transform operational performance and product quality.

Tips for Ensuring Proper Maintenance and Longevity of Your Sanitary Tubing Systems

When it comes to maintaining sanitary tubing systems, paying attention to the details can significantly extend their lifespan and enhance performance. Regular inspections are crucial. Just like aircraft mechanics meticulously check flexible hoses, businesses should adopt a similar approach to their sanitary tubing. Inspecting for signs of wear, kinks, or leaks can prevent larger issues down the line. It is also important to clean the tubing regularly to eliminate any build-up that could compromise hygiene and functionality.

Additionally, environmental factors play a vital role in the longevity of sanitary tubing. Reducing moisture around the tubing and ensuring proper storage conditions can help mitigate the risk of microbial growth and material degradation. By implementing these careful maintenance habits—akin to those recommended for washing machines and garden hoses—businesses can ensure that their sanitary tubing systems operate efficiently and reliably for years to come. Emphasizing the importance of proper care and maintenance is essential for sustaining the integrity of these vital systems.

Related Posts

-

7 Best Practices for Choosing Sanitary Pipe Fittings for Your Business

-

How to Choose the Right Sanitary Pipe Fittings for Your Plumbing Needs

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

7 Essential Insights about Steel Fittings for Optimal Performance

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs