Top 10 Valve Fittings for Efficient Fluid Control Solutions?

In the world of fluid control, valve fittings play a crucial role. These components ensure that fluids flow efficiently through various systems. They come in many shapes and materials, impacting performance and reliability. Choosing the right valve fittings can be challenging.

Many industries rely on these fittings for their operations. For instance, the oil and gas sector needs robust and durable fittings. In contrast, food and beverage industries require fittings that meet strict hygiene standards. The variety of applications makes it essential to understand different types.

There are common mistakes when selecting valve fittings. Oversights can lead to leaks or inefficiencies. For example, ignoring the pressure ratings and compatibility can result in costly failures. A careful approach is necessary for optimal performance. Understanding specifications and requirements is key. This exploration will unveil the top 10 valve fittings suitable for various fluid control solutions.

Overview of Valve Fittings and Their Importance in Fluid Control

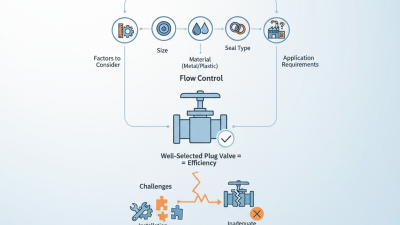

Valve fittings are essential in fluid control systems. They regulate the flow, pressure, and direction of various liquids and gases. These fittings come in various designs and materials. Each type serves a specific purpose that enhances efficiency and safety. For instance, ball valves offer an excellent sealing capability. They easily control flow with a simple quarter turn.

Consider the importance of selecting the right valve fitting. A wrong choice can lead to leaks or failed operations. Fluid dynamics play a critical role here. Many overlook the need for precise calculations and specifications. It's vital to consider factors like temperature and pressure ratings. Fittings that can’t withstand operational demands may fail unexpectedly.

When evaluating options, think of the long-term implications. Not all fittings are created equal. Sometimes, the most affordable choice is not the best. Investing in quality valve fittings can save maintenance costs in the long run. It’s also important to regularly inspect valves. Hidden wear can compromise system performance. Adapting a proactive maintenance strategy can minimize unforeseen issues.

Top 10 Valve Fittings for Efficient Fluid Control Solutions

This bar chart represents the efficiency ratings of the top 10 valve fittings used in fluid control solutions, rated from 1 to 10. Higher ratings indicate better efficiency in controlling fluid flow.

Types of Valve Fittings Used in Various Industries

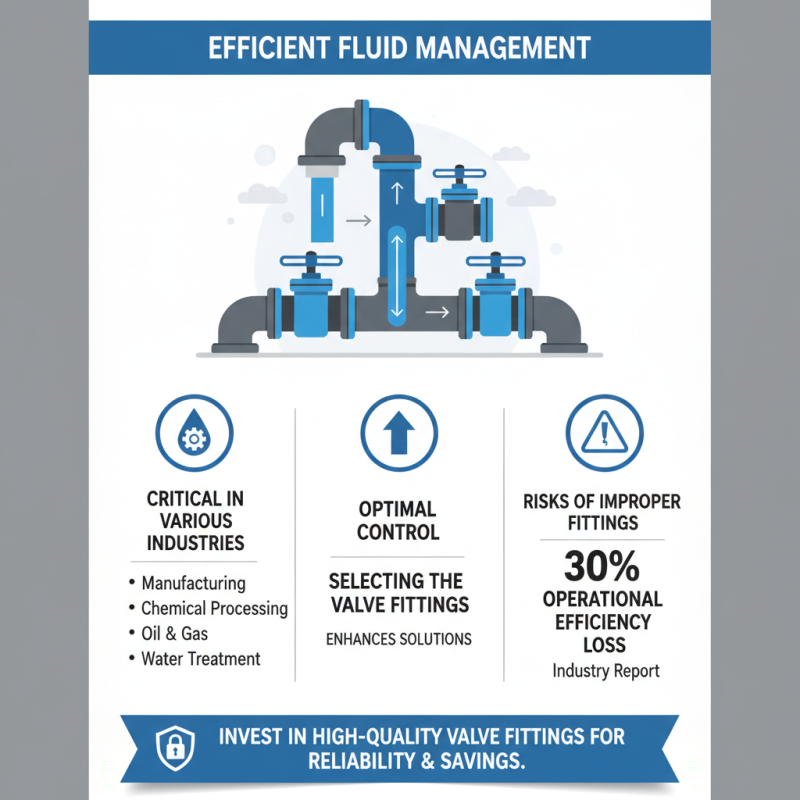

Valve fittings play a crucial role in fluid control across diverse industries. They ensure proper flow, pressure regulation, and effective isolation. In the oil and gas sector, for instance, over 60% of operations rely on efficient valve systems. In chemicals, robust fittings withstand corrosive substances. A recent industry report highlighted that almost 50% of process downtime results from valve failure.

In manufacturing, pneumatic and hydraulic systems depend on reliable valve fittings. Pneumatic valves are essential for controlling air supply, while hydraulic valves manage fluid power. In food and beverage, sanitary fittings maintain hygiene standards. The global market for valve fittings is anticipated to grow by 4% annually, indicating a rising demand for efficiency and safety.

However, not all fittings meet industry standards. Quality control remains a challenge. Misalignment and improper installation can lead to leaks. Regular maintenance is often overlooked, leading to unexpected failures. As industries evolve, so should our approach to valve fitting technology. Adopting innovative materials and smart solutions can significantly enhance performance.

Criteria for Selecting the Best Valve Fittings

When selecting valve fittings for efficient fluid control, several criteria play a crucial role. A recent industry report indicates that fluid control systems account for 28% of energy consumption in industrial processes. This highlights the impact of choosing the right fittings, influencing both energy efficiency and operational costs.

Measurement accuracy is vital. Properly calibrated fittings ensure that fluid flow is consistent and reliable. Materials also matter; corrosion-resistant options expand the lifespan of the fittings. A study by the Fluid Systems Association states that fittings made from high-quality stainless steel can last five times longer in harsh environments compared to standard materials.

Fittings must suit specific applications. Consider pressure ratings and temperature tolerances. Often, installations face retrofitting challenges. Compatibility with existing systems can lead to unforeseen setbacks. Balancing all these factors can be overwhelming, yet it’s essential for optimal performance. Reflecting on these elements helps prevent costly mistakes that many industries face when choosing valve fittings.

Top 10 Valve Fittings for Optimal Fluid Management Solutions

Efficient fluid management is critical in various industries. Selecting the right valve fittings can significantly enhance fluid control solutions. According to a recent industry report, improper fittings can lead to a 30% loss in operational efficiency. Thus, investing in high-quality valve fittings is essential.

When choosing valve fittings, consider the material compatibility. Different fluids require specific materials to prevent corrosion and degradation. For example, stainless steel fittings work well with many chemicals but can be expensive. Always assess the cost versus the potential for leaks or failures.

Tip: Regularly inspect your valve fittings to ensure they function properly. Sometimes, tiny leaks go unnoticed but can add up to significant issues over time.

Another important aspect is the size of valve fittings. Inadequate sizing can restrict flow rates and reduce system efficiency. An oversized fitting may appear beneficial but can lead to turbulence and increased wear. Manufacturers often recommend standard sizing charts for optimal performance.

Tip: Keep a log of your fittings. Document changes to monitor trends and address issues proactively. Adjusting your strategy based on data can lead to better outcomes.

Future Trends in Valve Fitting Technologies and Applications

The future of valve fitting technologies is evolving rapidly. Advances in smart technology are transforming traditional systems. Sensors are now integrated into fittings, allowing real-time data monitoring. This capability enhances efficiency and minimizes leaks. Yet, the reliance on digital solutions introduces vulnerabilities. Cybersecurity becomes an essential consideration for manufacturers.

Sustainability is a growing trend in fluid control. Eco-friendly materials are gaining traction. Many manufacturers are exploring biodegradable options for fittings. At the same time, efficiency remains a top priority. There’s a balancing act between performance and environmental impact. Innovations in design can limit waste but may also increase costs.

Adoption of automation is reshaping industries. Robotic systems are being employed for precise control. This can streamline operations but might lead to job displacement. The shift towards automation raises questions about workforce adaptation. Will workers have the skills required for these changes? As the industry advances, we must critically assess the implications of these trends.

Top 10 Valve Fittings for Efficient Fluid Control Solutions

| Rank | Type of Valve Fitting | Material | Pressure Rating (psi) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| 1 | Ball Valve | Stainless Steel | 1500 | -20 to 300 | Water, Oil |

| 2 | Butterfly Valve | PVC | 200 | -10 to 140 | Chemical Processing |

| 3 | Gate Valve | Ductile Iron | 250 | -10 to 400 | Water Supply |

| 4 | Check Valve | Brass | 300 | -40 to 250 | Gas Flow |

| 5 | Globe Valve | Carbon Steel | 1500 | -20 to 450 | Steam, Oil |

| 6 | Pressure Relief Valve | Aluminum | 400 | -40 to 300 | Industrial |

| 7 | Solenoid Valve | Plastic | 150 | 0 to 140 | Automation |

| 8 | Actuated Valve | Stainless Steel | 2000 | -20 to 210 | Oil and Gas |

| 9 | Y- strainer | Brass | 150 | -10 to 250 | Filtration |

| 10 | Flow Control Valve | Aluminum | 100 | -20 to 180 | Water Treatment |

Related Posts

-

Understanding the Types of Tubing Fittings for Optimal Performance

-

How to Choose Plug Valves for Your Industrial Applications?

-

Exploring Fittings Steel Market Growth at the 138th Canton Fair in 2025 with Key Industry Insights

-

Top 10 Benefits of Using Plug Valves in Industrial Applications?

-

Top Strategies for Enhancing Performance with Fittings Valves

-

6 Tips to Choose the Right Sanitary Connectors for Optimal Hygiene Compliance