Top 10 Stainless Steel Fittings You Must Know About?

In today's industrial landscape, stainless steel fittings play a crucial role. According to a recent market analysis by Smithers Pira, the demand for stainless steel fittings is expected to grow at a rate of 5.3% annually. This growth highlights the significance of these components in various sectors, including construction and manufacturing.

Expert Michael Johnson, a senior engineer in the plumbing industry, once stated, "Understanding stainless steel fittings is essential for ensuring system integrity." His insights emphasize the importance of selecting the right fittings to prevent failures. Despite their durability, many still overlook the critical specifications.

In a world where quality matters, the complexity of stainless steel fittings shouldn't be ignored. While some professionals may rush to make decisions, proper knowledge is vital. Understanding the various types and applications can significantly impact performance and safety.

Understanding Stainless Steel Fittings and Their Applications

Stainless steel fittings are widely used in various industries. They provide durability and resistance to corrosion. These fittings come in different forms, such as elbows, tees, and reducers. Each type serves a specific purpose in pipe systems. For example, elbows allow for directional changes, while tees enable branching.

The applications of stainless steel fittings range from plumbing to food processing. In plumbing systems, they ensure leak-free connections. In food industries, their hygienic properties are crucial. Yet, not all fittings are created equal. Some may not withstand high pressures or extreme temperatures. This can lead to failures. Choosing the right fitting requires careful consideration of factors like material grade and design.

Many wonder about the best fitting for their needs. The truth is, each application presents unique challenges. One fitting may excel in some areas but falter in others. Mistakes in selection can lead to significant problems. Ensuring proper installation is equally important, as it affects performance. Understanding these nuances is key to making informed decisions.

Types of Stainless Steel Fittings and Their Characteristics

Stainless steel fittings come in various types, each with unique characteristics. Understanding these can help in choosing the right ones for specific applications. For example, butt-weld fittings are widely used in high-pressure systems due to their strong connections. According to the American Society of Mechanical Engineers (ASME), these fittings can handle pressures exceeding 10,000 psi in some cases, making them suitable for critical installations.

Another common type is threaded fittings. They offer ease of installation and are ideal for low-pressure applications. However, they are not as robust as welded options. Industry reports indicate that threaded fittings can corrode faster in certain environments, which is a consideration in moisture-prone areas. Additionally, using the wrong type of fitting can lead to leaks. This highlights the importance of selecting the suitable fitting based on conditions they will face.

Flange fittings are another essential type. They are easier to assemble and disassemble, providing flexibility in maintenance. However, they may require gaskets, adding complexity to their use. Reports suggest that improper installation of flange fittings can cause failures, especially in high-stress environments. Each type of fitting has its advantages and potential pitfalls, underscoring the need for careful evaluation before sourcing materials.

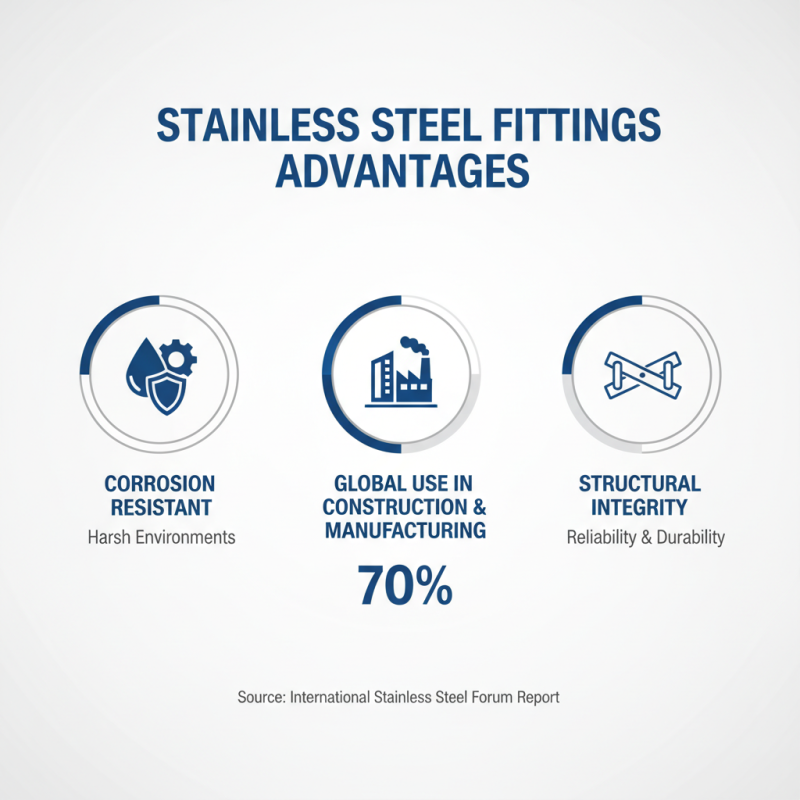

Key Benefits of Using Stainless Steel Fittings in Projects

Stainless steel fittings offer numerous advantages for various industrial projects. Their resistance to corrosion is notably significant, making them suitable for harsh environments. According to a report by the International Stainless Steel Forum, around 70% of stainless steel used globally is in construction and manufacturing. This highlights its importance in ensuring structural integrity.

Another key benefit is durability. Stainless steel fittings can withstand heavy loads and extreme temperatures. They are designed to last, with a lifespan often exceeding that of fittings made from other materials. Reports indicate that properly installed stainless steel fittings can remain functional for over 50 years. However, incorrect installation can compromise their longevity, raising concerns for many contractors and engineers.

Cost-effectiveness is another consideration. Although the initial cost may be higher, the long-term savings on maintenance and replacements are noteworthy. In some cases, stainless steel fittings can reduce overall project costs by up to 30% in the lifecycle analysis. Yet, the market remains competitive, and some may still overlook stainless steel in favor of cheaper alternatives. This raises questions about prioritizing upfront savings over long-term value.

Criteria for Selecting the Right Stainless Steel Fittings

When selecting stainless steel fittings, a few essential criteria can guide your decision. Consider the environment where the fittings will be used. Corrosion resistance is crucial, especially in humid or salty settings. Look for fittings with high-grade stainless steel. This significantly enhances durability. Weight and size matter too. Choose fittings that fit well within your existing framework.

Compatibility is another key factor. Ensure that the fittings match the pipes or tubes you are using. Mismatched sizes can lead to leaks. Take measurements carefully. Not all fittings are created equal. Some may not meet industry standards. Testing fittings before installation can save time and resources.

Also, examine the finish of the fittings. A smooth surface often leads to better flow rates. However, some might prefer a rougher finish for specific applications. Reflect on your specific needs. It might be beneficial to consult with experts for guidance. Balancing quality and cost is vital, but it can be challenging. Always prioritize performance over price.

Maintenance Tips for Longevity of Stainless Steel Fittings

Stainless steel fittings are durable but need care for longevity. Regular cleaning is essential. Use mild soap and water to avoid scratches. Rinse thoroughly to prevent water spots and mineral deposits. Cleaning too infrequently leads to corrosion. Be sure to dry the fittings after cleaning to eliminate moisture.

Inspect your fittings often. Look for any signs of wear or rust. Even stainless steel can corrode if not maintained properly. Tighten loose fittings to prevent leaks. Over time, screws and bolts can become loose. This can lead to bigger issues and costly repairs. If you notice a problem, address it immediately.

Be mindful of the environment. Chlorides from salt or certain chemicals can damage the fittings over time. If your location has high salinity, extra care is necessary. Consider applying a protective coating for additional safeguarding. If you are unsure about the maintenance process, seek advice. Always learn and adapt your care routine for the best results.

Maintenance Tips for Longevity of Stainless Steel Fittings

Related Posts

-

Why Are Stainless Steel Fittings Preferred in Construction?

-

6 Tips to Choose the Right Sanitary Connectors for Optimal Hygiene Compliance

-

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

-

The Complete Guide to Choosing the Right Stainless Steel Fittings for Your Plumbing Projects

-

How to Choose the Right Stainless Sanitary Fittings for Your Project

-

7 Essential Insights about Steel Fittings for Optimal Performance