Top 5 Sanitary Valves and Fittings You Need to Know?

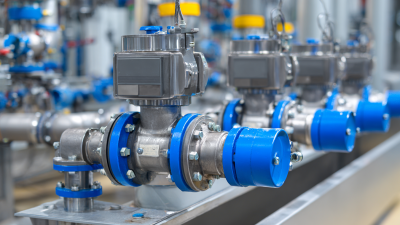

In the world of food and beverage manufacturing, sanitary valves and fittings play a crucial role. According to industry expert Dr. Emily Johnson, “The right sanitary valves can elevate product quality and ensure safety.” These components are essential for maintaining hygiene standards. They facilitate the seamless flow of liquids while preventing contamination.

Sanitary valves and fittings come in various shapes and sizes. Understanding their functionalities is key to enhancing operational efficiency. A poorly chosen valve can lead to significant losses and safety hazards. This emphasizes the importance of proper selection and maintenance.

However, many still overlook details like material compatibility and pressure ratings. A small oversight can have substantial repercussions. Industry professionals must remain vigilant when working with sanitary systems. Continuous learning and adaptation are necessary in this evolving field.

Understanding Sanitary Valves: Importance in Industrial Applications

Sanitary valves are critical in industries like food processing, pharmaceuticals, and biotechnology. They ensure the integrity and safety of fluids used in manufacturing. According to a report by the International Journal of Food Engineering, up to 80% of contamination in these sectors can be traced back to improper valve management. This highlights the need for proper sanitary valve selection and maintenance.

Understanding the design and function of sanitary valves is vital. These valves are engineered to prevent leakage and contamination. Their smooth surfaces facilitate easy cleaning, as required by industry standards. A study by the FDA found that valves with crevices can harbor bacteria, increasing the risk of product spoilage. Regular inspections and adherence to maintenance protocols are necessary, but many facilities overlook this.

Moreover, the materials used in manufacturing these valves play a key role. Stainless steel is the predominant choice due to its corrosion resistance and durability. However, improper installation can negate these advantages. Facilities often struggle with installation errors, leading to costly leaks and downtime. It’s a reminder that even small decisions, like valve selection and fitting, can have significant impacts on overall production efficiency and safety.

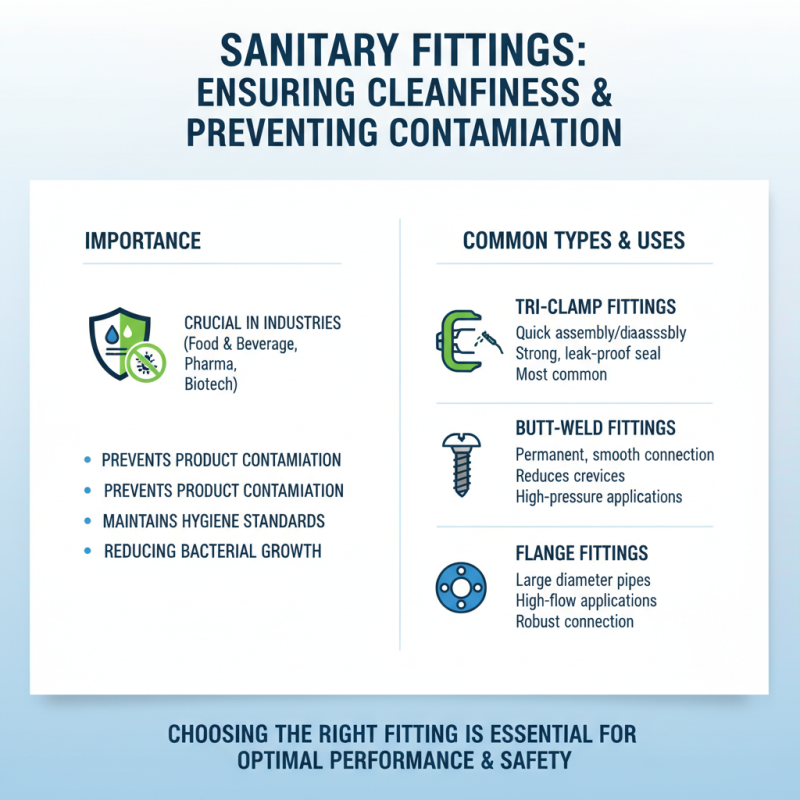

Types of Sanitary Fittings: An Overview of Common Variants

Sanitary fittings are crucial in many industries. They ensure cleanliness and prevent contamination. Various types of fittings serve different purposes. Understanding these types is essential for proper application.

One common type is the clamp fitting. This fitting allows easy assembly and disassembly. It is simple and often used for quick maintenance. However, it may not always provide a perfect seal. Learning to choose the right sealing method for it is vital. Another important fitting is the threaded fitting. It offers reliable connections but can be tough to clean.

Then, there are tri-clamp fittings. These fittings are popular in food and beverage industries. They make cleaning easier, yet can be bulky in some setups. A well-placed corner fitting can save space and improve flow. Remember, the choice of fittings directly impacts system efficiency. Each type has its pros and cons, leading to the need for thoughtful selection.

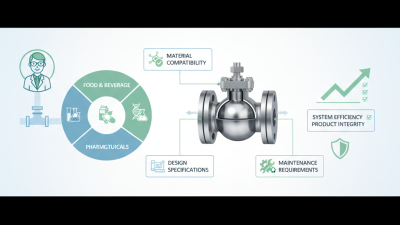

Key Features to Consider When Choosing Sanitary Valves and Fittings

When selecting sanitary valves and fittings, several key features come into play. First, consider the material. Stainless steel is commonly used due to its resistance to corrosion and ability to withstand high pressure. However, not all stainless steel is created equal. Understanding the grade of steel is essential for optimal performance.

Another important aspect is the sealing type. Elastomer seals are popular, but they may degrade over time. Teflon seals offer better longevity but can be costlier. Assess the application needs carefully. Some installations may require specific sealing solutions, and that’s a point worth reflecting on.

Maintenance is also a vital factor. Look for fittings that allow easy disassembly. This simplifies inspections and cleaning, ensuring hygiene standards are maintained. Regular checks can prevent costly replacements later on.

**Tips:** Always keep spare parts handy. It reduces downtime dramatically. Consider the flow characteristics of the fittings too. That can impact system efficiency and performance.

Top 5 Recommended Brands for Sanitary Valves and Fittings

When choosing sanitary valves and fittings, several prominent brands stand out. These brands are known for their reliability and performance in clean environments. A recent industry report indicated that the global sanitary valves market was valued at approximately $3.9 billion in 2022. This number is projected to grow at a compound annual growth rate of around 5.2% through 2030. Such growth reflects the increasing demand for hygiene and safety in food and beverage, pharmaceutical, and biotechnology sectors.

Additionally, industry experts emphasize the importance of material quality. Stainless steel is a preferred choice due to its corrosion resistance and durability. However, not all stainless steel is created equal. Differences in alloy composition can affect longevity and performance. Many brands offer a range of grades, each suited for specific applications. Lower-grade materials may save money upfront but can lead to increased maintenance costs over time.

Despite advancements in technology, some issues remain. Not all manufacturers maintain consistent quality control. This inconsistency can result in operational challenges down the line. It's also crucial to ensure that the fittings match the specific application requirements. Misalignment in specifications can lead to leaks or failures, creating unnecessary risks in sanitary systems. Understanding these nuances is essential for making informed decisions in the vast market of sanitary valves and fittings.

Top 5 Sanitary Valves and Fittings You Need to Know

Maintenance Tips for Longevity of Sanitary Valves and Fittings

Sanitary valves and fittings are crucial in maintaining hygiene in various industries. Proper maintenance enhances their lifespan significantly. Regular checks can prevent major issues. Inspect for leaks or cracks. These small problems can escalate quickly if not addressed.

Cleaning is essential. Use appropriate cleaning solutions to avoid damage. Avoid harsh chemicals, as they can degrade materials over time. Rinse thoroughly afterward. Ensure all components are dry before reassembly to prevent corrosion.

Proper storage is also vital. Store valves away from direct heat or sunlight. Extreme temperatures can warp materials. Ensure fittings are kept in a clean, dry environment. It might feel tedious, but consistent care will pay off in longevity. Consider checking seals and gaskets regularly, as they wear out more quickly than you might think.

Related Posts

-

2025 Guide: How to Choose the Right Sanitary Ball Valves for Your System

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries

-

Why You Need a Comprehensive Sanitary Fittings Catalog for Your Projects

-

Why Sanitary Connectors Are Essential for Maintaining Hygiene in Food Production