Top 10 Pump Valves Types for Optimal Fluid Control Solutions

In the rapidly evolving landscape of fluid control, the selection of appropriate pump valves is crucial for ensuring optimal performance and efficiency. According to a report by MarketsandMarkets, the global pump market is projected to reach USD 81.4 billion by 2025, driven by the increasing demand for water and wastewater management, as well as industrial applications. Within this market, pump valves play a pivotal role in regulating flow, controlling pressure, and maintaining system integrity across various industries, including oil and gas, chemical processing, and water treatment.

The diversity of pump valves available in the market allows for tailored solutions that meet specific operational requirements. Each type of pump valve offers distinct advantages, whether it’s for handling corrosive fluids, managing high pressure, or ensuring leak-free operations. Industry experts emphasize that understanding the functions and benefits of different pump valve types is essential for optimizing fluid control solutions. As companies strive to enhance operational efficiency and reduce downtime, the strategic selection of the right pump valves becomes a key factor in achieving overall system reliability and performance.

Overview of Pump Valves and Their Importance in Fluid Control

Pump valves play a critical role in fluid control systems, providing essential functionality to manage the flow, pressure, and direction of fluids. These components are designed to regulate and maintain specific flow conditions in various applications, from industrial processes to water treatment facilities. By ensuring that fluids move efficiently within a system, pump valves help optimize operation, reduce energy consumption, and improve overall system reliability.

The importance of pump valves extends beyond mere control of fluid dynamics; they are integral to safety and environmental protection in many industries. Well-designed pump valves prevent backflow, manage pressure surges, and can isolate sections of a system for maintenance without disrupting the entire operation.

The selection of appropriate pump valve types is influenced by factors such as fluid characteristics, temperature, and system pressure requirements. Understanding the various types available can help engineers and operators make informed decisions that enhance performance and ensure the longevity of fluid control systems.

Common Types of Pump Valves and Their Applications

When it comes to optimal fluid control solutions, understanding the different types of pump valves and their specific applications is crucial. Pump valves play a vital role in regulating flow, controlling pressure, and ensuring efficient operation in various systems.

One common type of pump valve is the check valve, which allows fluid to flow in one direction while preventing backflow. This is essential in applications such as water supply systems, where maintaining pressure is vital.

Another prevalent option is the globe valve, known for its ability to regulate flow effectively by increasing resistance to fluid movement. Globe valves are often used in heating and cooling systems to manage fluids at varying temperatures.

Tips: Always consider the viscosity and temperature of the fluid when selecting a valve type to optimize performance. Additionally, regular maintenance of pump valves can prevent leaks and extend their lifespan. Understanding the specific requirements of your system will guide you in choosing the right valve, enhancing overall efficiency and reliability.

Key Features to Consider When Choosing Pump Valves

When selecting pump valves for optimal fluid control, several key features should be at the forefront of your decision-making process. Firstly, the valve material is paramount; it must be compatible with the fluids being handled to prevent corrosion and ensure longevity. Common materials include stainless steel, PVC, and brass, each offering distinct advantages depending on the application. Additionally, the valve's pressure and temperature ratings are crucial, as these specifications determine the valve's ability to operate safely and effectively under the conditions of your system.

Another important aspect to consider is the valve type, which influences the flow characteristics and control precision. For instance, globe valves are excellent for throttling, while check valves are essential for preventing backflow. The actuation method also plays a significant role; hydraulic, pneumatic, or electric actuators each offer different levels of control and response times. Finally, ease of maintenance and the availability of replacement parts should not be overlooked, as these factors can greatly impact the overall efficiency and operational costs of your fluid control system.

Advantages and Disadvantages of Different Pump Valve Types

When selecting pump valves, understanding the advantages and disadvantages of various types is crucial for effective fluid control solutions. One common type, the globe valve, offers excellent throttling capabilities, allowing for precise flow regulation. However, its design can lead to increased pressure drops and reduced energy efficiency when compared to other valve types, which might be a drawback in large-scale operations.

Another widely used valve is the ball valve, known for its quick shut-off capabilities and durability. Ball valves provide minimal flow resistance, making them ideal for on/off applications. Nonetheless, they are less suited for applications requiring frequent throttling due to the potential for flow turbulence and limited regulation capability, which might compromise system performance in certain fluid control scenarios. Understanding these trade-offs will assist in selecting the optimal valve type for specific needs and applications.

Top 10 Pump Valves Types for Optimal Fluid Control Solutions - Advantages and Disadvantages of Different Pump Valve Types

| Pump Valve Type | Advantages | Disadvantages |

|---|---|---|

| Globe Valve | Excellent flow regulation; good for throttling | Higher pressure drop; not suitable for on/off control |

| Gate Valve | Minimal pressure drop; good for on/off service | Not good for throttling; can wear out over time |

| Ball Valve | Quick to open/close; low flow resistance | Not ideal for throttling; can get stuck if not used |

| Butterfly Valve | Lightweight; low-cost; quick operation | Limited to low-pressure applications; can cause turbulence |

| Check Valve | Prevents backflow; simple design | Limited functionality; can be noisy |

| Pinch Valve | Good for slurries; simple design with little maintenance | Can wear out depending on media; limited to specific applications |

| Diaphragm Valve | Good for sanitary applications; leak-proof | Higher cost; limited temperature range |

| Solenoid Valve | Fast operation; good for automation | Limited pressure and temperature range; can be noisy |

| Thermostatic Valve | Automatic temperature regulation | Requires calibration; can be complex |

| Pressure Relief Valve | Prevents overpressure; enhances safety | Can leak if not maintained properly; limited to pressure control |

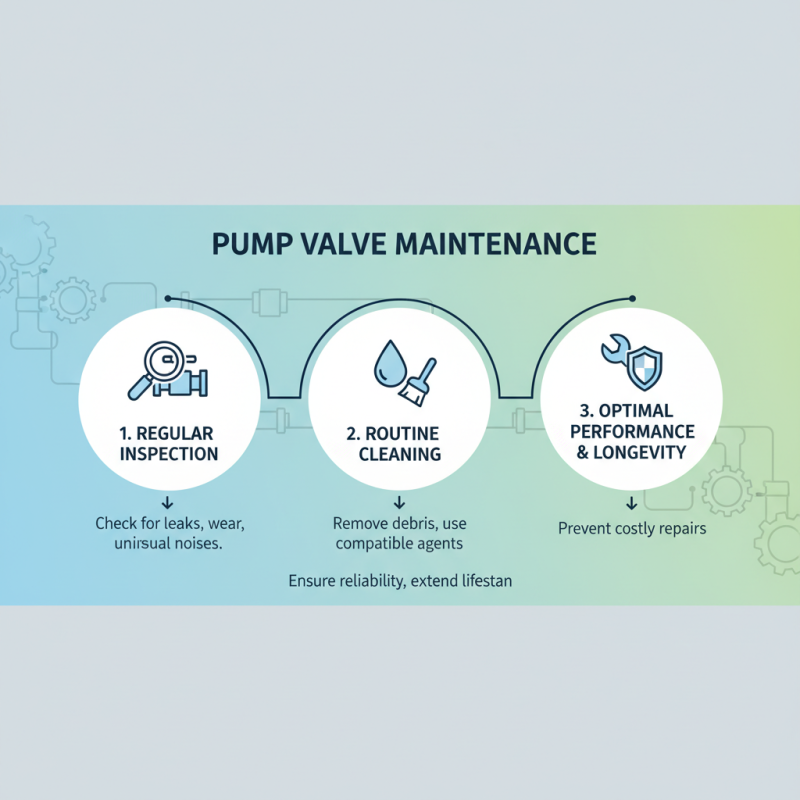

Maintenance Tips for Optimal Performance of Pump Valves

Proper maintenance of pump valves is essential to ensure optimal performance and longevity. Regular inspection is crucial; operators should check for signs of wear and tear, such as leaks or unusual noises. This can help identify potential issues before they escalate into costly repairs. Cleaning should be performed routinely, as the accumulation of debris can affect the valve's functionality. Using appropriate cleaning agents that are compatible with the materials of the valve and fluid being transferred is crucial to avoid damage.

Another important aspect of maintenance is lubrication. Ensuring that components are well-lubricated reduces friction and extends the lifespan of the valve. Care should be taken to follow manufacturer guidelines regarding lubrication frequency and the type of lubricant used. Additionally, pressure and flow rates should be monitored to ensure they remain within recommended limits, allowing for adjustments to be made when necessary. Implementing these proactive maintenance practices will enhance the reliability of pump valves, ultimately leading to more efficient fluid control solutions.

Related Posts

-

Top 10 Best Pump Valves for Optimal Performance in Industrial Applications

-

How to Select the Right Pump Valves for Your Industrial Applications

-

How to Choose the Right Fittings and Valves for Your Industrial Needs

-

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries

-

2025 Top Water Fittings: Essential Guide to Choosing the Best Options

-

Understanding Valve Fittings: Key Trends and Innovations Driving Industry Growth in 2023