Top 10 Diaphragm Valves You Should Know About?

Diaphragm valves play a crucial role in fluid control across various industries. Renowned industry expert Dr. Sarah Emerson states, "The efficiency of diaphragm valves is unmatched in critical applications." This highlights their importance in ensuring system reliability and performance.

These valves are designed to prevent leaks and contamination. Their flexibility allows them to handle a wide range of fluids, from water to corrosive substances. Companies worldwide depend on diaphragm valves for precise flow control. Yet, some still struggle to recognize the importance of choosing the right materials for their specific applications.

Considering the variety of diaphragm valves available, it’s easy to feel overwhelmed. There are too many options with different specifications. However, understanding their unique features is vital. It influences not only the operational efficiency but also the longevity of the entire system. It's clear that while diaphragm valves offer numerous benefits, users must reflect on their choices carefully.

Understanding Diaphragm Valves: Definition and Functionality

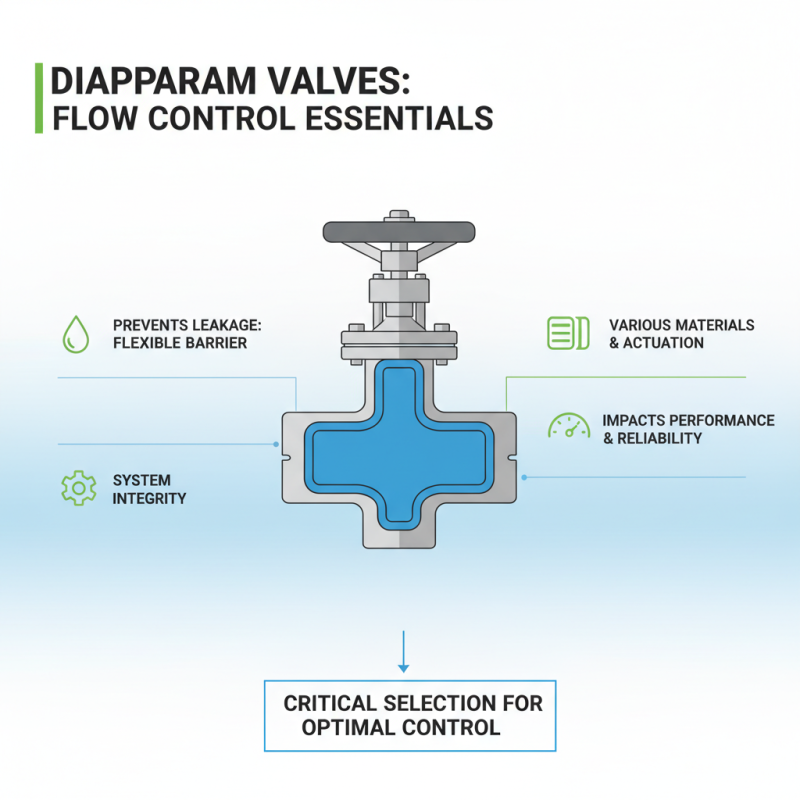

Diaphragm valves are essential components in various fluid control systems. Their primary function is to regulate the flow of liquids and gases. This is achieved through a flexible diaphragm that moves up and down to open or close the valve. When the diaphragm is lifted, fluid passes through. When it is pressed down, the flow is halted. Such movement allows for precise control and prevents leaks effectively.

These valves feature a simple yet effective design. Typically, they are made of durable materials that can withstand various environments. For instance, in a chemical plant, a diaphragm valve can handle corrosive substances without failing. However, not all diaphragm valves can adapt to extreme temperatures or pressures. This limitation requires careful selection based on application needs.

It's worth noting that diaphragm valves can sometimes face challenges. Over time, the diaphragm can wear out, leading to performance issues. Regular maintenance is essential to prolong their lifespan. Users may often overlook this aspect, assuming the valve will function indefinitely. Recognizing this need for upkeep can make a significant difference in performance and reliability.

Key Features and Advantages of Diaphragm Valves in Fluid Control

Diaphragm valves are crucial for fluid control in various applications. They utilize a flexible diaphragm to regulate the flow of liquids and gases. This design can effectively handle different media, including corrosive substances. Their ability to provide tight sealing enhances process safety and reliability. This is particularly important in industries like pharmaceuticals and food processing.

One highlight is the versatility of diaphragm valves. They can accommodate varying pressure and temperature ranges, making them suitable for many environments. Additionally, they require minimal maintenance, which saves time and costs. However, performance can be affected by factors such as diaphragm material or installation techniques. It's essential to choose the right components for optimal operation.

Another advantage lies in their simple design. Fewer moving parts mean reduced wear and tear. This simplicity also allows for easier disassembly and cleaning. Users sometimes overlook this benefit. Regular checks can prevent unexpected downtime. While diaphragm valves are generally reliable, designers must not underestimate the impact of fluid characteristics. These details can make a significant difference in their effectiveness.

Top 10 Diaphragm Valve Models: Performance and Reliability

Diaphragm valves are essential in various industries for their unique ability to control flow. Their design features a flexible diaphragm that acts as a barrier. This component prevents leakage, which is crucial for maintaining system integrity. Models vary widely in terms of materials and actuation methods. These differences impact performance and reliability, making selection critical.

Performance can hinge on the valve’s pressure rating and temperature tolerance. Some models excel at high pressures, while others work best in low-flow applications. Reliability is an ongoing concern. Over time, diaphragm wear can lead to performance issues. Regular maintenance can mitigate risks but may require careful planning. Industry feedback often highlights the need for timely inspections, especially in harsh conditions.

The right diaphragm valve can significantly influence system efficiency. However, it is not a one-size-fits-all solution. Each application presents unique challenges. Inconsistent performance can arise from improper sizing or material choice. This complexity requires a thoughtful approach to valve selection, underscoring the importance of understanding specific operational needs.

Applications of Diaphragm Valves in Various Industries

Diaphragm valves play a crucial role across various industries. Their design helps in regulating fluid flow, making them essential in several applications. In the pharmaceutical sector, these valves prevent contamination during drug production. They ensure sterile conditions, which is vital for patient safety.

In the food and beverage industry, diaphragm valves help maintain hygiene. They minimize dead zones where bacteria can grow. This feature is particularly important in processes like brewing or juice production. Workers often overlook proper valve maintenance, leading to potential contamination risks. Regular checks can mitigate these issues.

Chemical processing is another key area for diaphragm valves. They can handle corrosive fluids, providing safety and reliability. However, improper installation can lead to leaks. It’s crucial to train staff on correct handling techniques. In high-pressure situations, any oversight can have serious consequences.

Tip: Always inspect diaphragm seals for wear and tear. A small crack can lead to significant issues down the line. Ensure that your maintenance team understands the specific requirements of each valve type.

Maintenance and Selection Criteria for Diaphragm Valves

When selecting diaphragm valves, consider the application rigorously. Different materials suit various media. For example, demanding environments may require robust materials. Valves should be resistant to corrosion and pressure. Check if they can handle the specific temperature range. Affordable options often compromise on quality. Investing in durable materials is crucial.

Maintenance cannot be overlooked. Regular inspection helps identify issues early. A worn diaphragm can lead to leaks or system failure. Clean the valves periodically to prevent buildup. Lubrication is essential to keep the components operating smoothly. Develop a checklist for routine checks. Skipping maintenance can result in costly downtime. Reflect on your procedures, as thoroughness can prevent unexpected failures.

In terms of functionality, consider the actuator type. Manual valves require more effort to operate. Automated valves enhance efficiency but can fail unexpectedly. Each choice presents its own flaws. An intricate balance between initial cost and long-term reliability is necessary. Perhaps, reassess what works best for your operation to avoid future complications.

Top 10 Diaphragm Valves You Should Know About

| Valve Type | Material | Size Range (inches) | Pressure Rating (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Manual Diaphragm Valve | PVC | 0.5 - 6 | 150 | 32 - 140 | Water Treatment |

| Electric Actuated Diaphragm Valve | Stainless Steel | 1 - 4 | 200 | 32 - 185 | Chemical Processing |

| Pneumatic Diaphragm Valve | Brass | 1 - 8 | 150 | 40 - 150 | Pharmaceuticals |

| Lined Diaphragm Valve | PTFE | 2 - 10 | 300 | -40 - 250 | Corrosive Fluids |

| Sanitary Diaphragm Valve | 316 Stainless Steel | 0.5 - 4 | 150 | 32 - 185 | Food and Beverage |

| Control Diaphragm Valve | Carbon Steel | 1 - 12 | 250 | 32 - 200 | Industrial Applications |

| Heavy-Duty Diaphragm Valve | Ductile Iron | 2 - 12 | 400 | -20 - 250 | Waterworks |

| Bellow Sealed Diaphragm Valve | Alloy Steel | 1 - 6 | 600 | -50 - 300 | Oil and Gas |

| Nitrogen Purge Diaphragm Valve | PVDF | 0.5 - 4 | 150 | 32 - 140 | Laboratory Use |

Related Posts

-

Understanding the Role of Diaphragm Valves in Modern Industrial Applications

-

How to Choose the Right Diaphragm Valves for Your Industrial Applications

-

The Future of Diaphragm Valves Set to Transform Fluid Control Technologies

-

Understanding Valve Fittings: Key Trends and Innovations Driving Industry Growth in 2023

-

Why Are Sanitary Connectors Essential for Food Safety?

-

10 Best Water Valves for Optimal Flow Control in 2023