Essential Tips for Choosing the Right Brewery Fittings for Your Brewing Setup

When diving into the world of brewing, one of the most crucial aspects to consider is the choice of brewery fittings. These components, though often overlooked, play an essential role in the efficiency and quality of your brewing setup. From valves and connectors to hoses and fittings, the right choices can streamline your brewing process and enhance overall performance. As a brewer, whether you're a novice or an experienced artisan, understanding the different types of brewery fittings and how they interact with your brewing system is vital for achieving the best results.

In this guide, we will explore key factors to consider when selecting brewery fittings that cater to your unique brewing needs. We’ll discuss materials, compatibility, and maintenance, ensuring you have a comprehensive understanding of how to optimize your setup. With the appropriate knowledge and planning, you can enhance the functionality and reliability of your entire brewing operation, making the brewing experience more enjoyable and successful. By focusing on these essential tips, you’ll be well on your way to creating the perfect brewing environment tailored specifically to your preferences.

Understanding Brewery Fittings: Types and Functions

When setting up a brewing system, understanding the various types of brewery fittings and their functions is crucial. Brewery fittings can include components such as valves, hoses, connectors, and clamps, each designed to ensure smooth operation and optimal performance. For instance, valves are vital for controlling the flow of liquids, while clamps secure connections to prevent leaks. Familiarity with these components will help you make informed decisions that enhance the efficiency and safety of your brewing process.

**Tip:** Always consider the compatibility of fittings with your brewing equipment. Misalignment in sizes or materials can lead to operational issues or contamination.

Moreover, it’s essential to choose fittings made from food-grade materials, which ensures that your brewing ingredients remain uncontaminated. Different types of tubing may be required for various processes, such as transferring hot liquids or carbonated beverages. Selecting the right type of flexible tubing can significantly affect your workflow and the integrity of your final product.

**Tip:** Invest in stainless steel fittings where possible, as they offer durability and are easy to clean, reducing the risk of cross-contamination between batches.

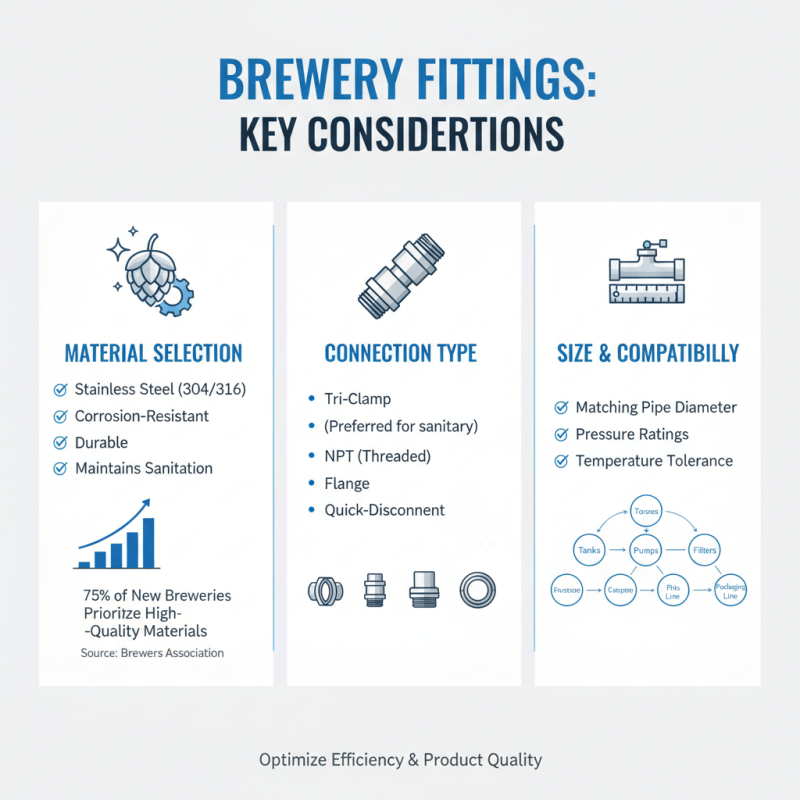

Key Considerations for Selecting Brewery Fittings

When selecting brewery fittings for your brewing setup, several key considerations can significantly impact both the efficiency of your operations and the quality of your product. Firstly, material selection is crucial; fittings made from stainless steel are favored due to their corrosion resistance, durability, and ability to maintain sanitation, which is essential in brewing. According to a report by the Brewers Association, nearly 75% of new breweries prioritize equipment made from high-quality materials to ensure long-lasting functionality and food safety.

Moreover, compatibility with existing equipment cannot be overlooked. This includes taking into account the dimensions and specifications of your brewing system. Industry studies indicate that improper sizing of fittings can lead to inefficiencies, contributing to potential losses of up to 10% in brewing yield. Ensuring that fittings can handle the necessary pressure and temperature requirements is equally important. It is estimated that over 64% of breweries have experienced equipment failure due to mismatched fittings, leading to production downtime and costly repairs. Therefore, investing time in selecting the right fittings tailored to your specific brewing setup is vital for maintaining operational efficiency and product quality.

Material Options for Brewery Fittings: Pros and Cons

When it comes to brewery fittings, the choice of material is crucial, as it can significantly affect both the performance and longevity of your brewing setup. Among the most common materials used for brewery fittings are stainless steel and plastic.

Stainless steel is favored for its durability, resistance to corrosion, and ability to withstand high temperatures and pressures. These characteristics make it ideal for various brewing processes, including boiling and fermentation. However, it tends to be more expensive upfront, which can be a consideration for tight budgets.

On the other hand, plastic fittings are lighter and often more cost-effective, making them a popular choice for smaller or home brewing operations. They are resistant to chemical reactions, which helps in maintaining the integrity of the brewing ingredients. However, plastic may not hold up as well under extreme temperatures or heavy-duty use compared to metal options. Furthermore, certain types of plastic can degrade over time when exposed to high temperatures or UV light, potentially affecting the quality of the brew. Understanding the pros and cons of each material will help you make an informed decision that best fits your brewing needs.

Sizing and Compatibility: Ensuring a Proper Fit

When setting up a brewing system, the importance of proper sizing and compatibility of brewery fittings cannot be understated. The fittings, which include items such as couplings, valves, and hoses, must be selected based on the specific dimensions and requirements of your equipment. Misjudging the size of fittings can lead to leaks, inefficiencies, and costly downtime. Therefore, it's crucial to meticulously measure the inlet and outlet sizes of your brewing vessels and ensure that the fittings you choose align with these measurements.

In addition to dimensional considerations, compatibility between different materials is essential for maximizing the efficiency and safety of your brewing setup. Fittings should match the material of your brewing equipment—whether it's stainless steel, PVC, or another type—to prevent corrosion or chemical reactions that could compromise the integrity of your brew. When selecting fittings, also consider the system's pressure and temperature requirements; fittings should be rated for the specific conditions they'll be subjected to during operation. By focusing on these aspects of sizing and compatibility, you can create a reliable and effective brewing environment that enhances your brewing experience.

Essential Tips for Choosing the Right Brewery Fittings for Your Brewing Setup - Sizing and Compatibility: Ensuring a Proper Fit

| Component | Size (inches) | Material | Compatibility | Notes |

|---|---|---|---|---|

| Barb Fitting | 1/2 | Plastic | Hoses, Brew Kettles | Commonly used for connecting hoses |

| Tri-Clamp Fitting | 2 | Stainless Steel | Fermenters, Brew Houses | Ideal for sanitary connections |

| NPT Fitting | 3/4 | Brass | Kettles, Pumps | Common for threaded connections |

| Quick Disconnect | 1 | Polymer | Hoses, Regulator | Allows for easy attachment/detachment |

| Ball Valve | 1/2 | Stainless Steel | Brew Kettles | Used for controlling flow |

Maintenance and Cleaning Tips for Brewery Fittings

Proper maintenance and cleaning of brewery fittings is crucial for ensuring the quality and safety of your brewing setup. Regular cleaning helps prevent the buildup of residue and contaminants that can affect the flavor and consistency of your beer. Begin by establishing a routine cleaning regimen immediately after each brewing session, using warm water and a mild detergent to remove any visible debris. Pay close attention to fittings that are often overlooked, such as gaskets and seals, as these components can harbor bacteria if not adequately cleaned.

In addition to regular cleaning, it’s essential to perform thorough inspections of your fittings to identify any signs of wear or damage. Over time, fittings can develop leaks or corrosion, which could compromise the integrity of your brewing system. Replace any worn-out components promptly and ensure that all connections are secure. Additionally, consider using sanitizing solutions between brewing cycles to minimize microbial growth. By prioritizing maintenance and cleanliness, you can enhance the longevity of your brewery fittings and maintain a high standard in your brewing operations.

Essential Tips for Choosing the Right Brewery Fittings

This bar chart illustrates the number of recommended maintenance actions for different types of brewery fittings. Proper maintenance is essential to ensure the longevity and efficiency of your brewing setup.

Related Posts

-

7 Compelling Reasons to Choose the Right Brewery Fittings for Your Craft Business

-

Essential Guide to Choosing the Right Valve Fittings for Optimal Performance

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

The Ultimate Guide to Choosing the Right Ball Valves for Your Plumbing Projects

-

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing

-

How to Choose the Right Ball Valves for Your Industrial Applications