Why Are Stainless Steel Fittings Preferred in Construction?

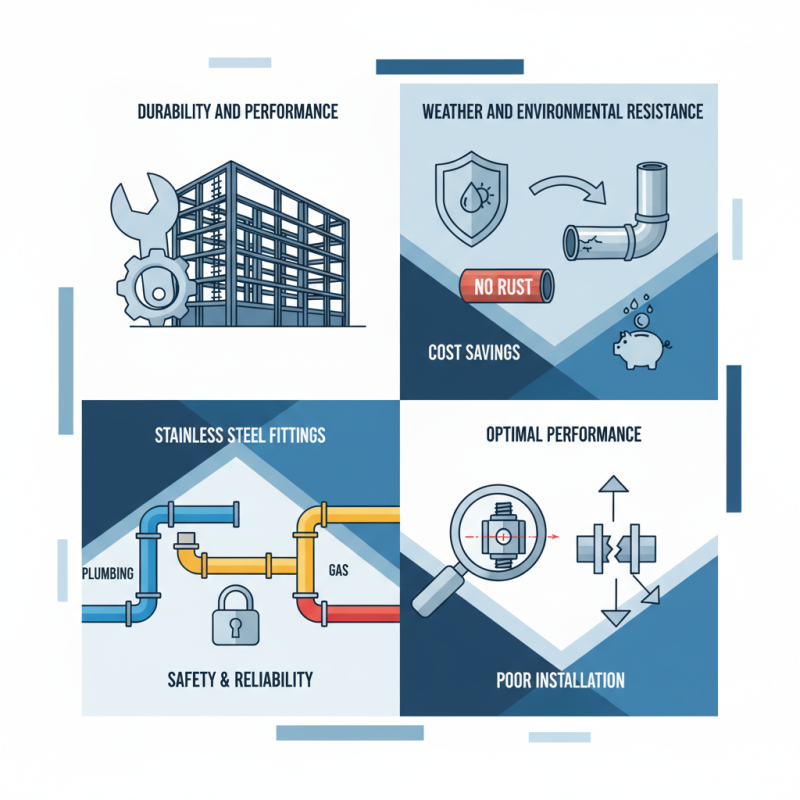

In construction, the choice of materials plays a critical role in durability and performance. Stainless steel fittings have emerged as a preferred option among professionals. According to John Smith, a leading expert in structural engineering, "Stainless steel fittings offer unmatched strength and corrosion resistance, making them ideal for diverse applications." This highlights the significance of these components in building projects.

The durability of stainless steel fittings lies in their resistance to weather and environmental factors. Unlike other materials, they do not rust easily. This longevity can save costs over time. However, some may argue that stainless steel fittings can be more expensive upfront. Despite this, their overall value often justifies the investment.

Moreover, these fittings contribute to the safety and reliability of structures. They are widely used in plumbing, gas, and electrical systems. Yet, it's essential to consider proper installation techniques. Poor installation can negate their benefits. Thus, a comprehensive understanding of stainless steel fittings is crucial for optimal performance in construction projects.

Advantages of Stainless Steel Fittings in Construction Applications

Stainless steel fittings are increasingly favored in construction due to their unique advantages. One major benefit is their resistance to corrosion. Unlike other materials, they do not rust easily, ensuring durability even in harsh environments. This quality is crucial for structures exposed to moisture or extreme weather.

Moreover, stainless steel fittings offer exceptional strength. They can withstand significant stress, which is essential in heavy-duty applications. This strength often leads to longer service life and reduced maintenance costs. Additionally, the aesthetic appeal of stainless steel cannot be overlooked. Its sleek finish enhances the overall look of a building.

However, it’s important to reflect on the higher initial cost associated with stainless steel. This can deter some builders, despite the long-term savings on maintenance. Sometimes, the heft and weight of these fittings can complicate installations. Careful planning and consideration are necessary to make the most of their benefits.

Corrosion Resistance and Durability of Stainless Steel Fittings

Stainless steel fittings are favored in construction due to their exceptional corrosion resistance and durability. According to a report from the European Commission, stainless steel can resist corrosion in a variety of environments. This includes harsh weather conditions and exposure to chemicals. This makes it ideal for outdoor structures and industrial applications.

Durability is critical for construction materials. Stainless steel fittings last longer than traditional materials, reducing the need for replacements. A study by the American Society of Civil Engineers highlights that these fittings can last over 50 years with minimal maintenance. This longevity translates into cost savings over time, although initial costs might be higher.

There are still challenges. Stainless steel can be more expensive to source than other materials. In some instances, improper installation can lead to failure. Training workers to handle and install stainless steel correctly is essential. Despite these issues, the benefits of corrosion resistance and long-term durability make stainless steel fittings a preferred choice in the construction industry.

Cost-Effectiveness of Stainless Steel Over Time in Construction

Stainless steel fittings are an essential choice in construction. Their durability makes them appealing, but cost-effectiveness shines over time. While the initial price is higher than other materials, it pays off in the long run. This material resists corrosion and requires little maintenance. Thus, the life cycle cost reduces significantly.

When budgeting for a project, consider long-term savings. Investing in stainless steel can reduce future replacement costs. Over time, cheaper materials may fail and require more frequent repairs. This leads to unexpected costs and delays.

Tips: Always assess the environment where fittings will be used. In coastal regions, for instance, stainless steel proves even more vital due to salty air. Choosing the right material can lead to better performance and fewer issues later.

The ongoing maintenance of other materials can be frustrating. Regular checks and replacements erode any initial savings. Stainless steel fittings, on the other hand, require minimal upkeep. However, the upfront expense may cause concern for budget-conscious projects. Balancing initial costs with long-term benefits is key to wise investments in construction.

Sustainability and Environmental Impact of Using Stainless Steel Fittings

The construction industry is increasingly turning to stainless steel fittings. This shift is largely due to their sustainability and minimal environmental impact. Stainless steel is highly recyclable. In fact, most stainless steel products are made from recycled materials. This reduces the demand for virgin resources and lowers overall energy consumption.

Moreover, stainless steel fittings have a long lifespan. They resist corrosion and wear better than many alternatives. This durability means less frequent replacements, reducing construction waste. However, the production of stainless steel does still require significant energy and resources. It's essential for industries to consider the full lifecycle of materials before making choices.

While stainless steel is a sustainable option, it’s not without flaws. The mining of raw materials does impact ecosystems. The process can contribute to environmental degradation. Awareness of these issues is vital. Balancing the benefits and downsides leads to more informed decisions in construction practices. This reflection can pave the way for healthier choices in building a greener future.

Versatility of Stainless Steel Fittings in Various Construction Projects

Stainless steel fittings are widely used in various construction projects due to their versatility. They work well in both residential and commercial applications. From plumbing systems to structural support, these fittings offer exceptional strength. They resist corrosion, which makes them suitable for harsh environments. Builders appreciate their ability to collaborate with other materials.

In terms of design flexibility, stainless steel fittings can accommodate various shapes and sizes. This adaptability helps architects realize their visions. However, these fittings are sometimes more expensive than other materials. Cost is a significant consideration for many contractors. Some might hesitate to choose them, especially for large projects.

Installation poses another challenge. While stainless steel fittings are durable, they require expertise to install properly. Improper installation can lead to future issues. Builders must ensure they follow best practices. Overall, the advantages of stainless steel fittings often outweigh these drawbacks, making them a preferred choice in construction.

Related Posts

-

6 Tips to Choose the Right Sanitary Connectors for Optimal Hygiene Compliance

-

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

-

The Complete Guide to Choosing the Right Stainless Steel Fittings for Your Plumbing Projects

-

Essential Tips for Choosing the Right Brewery Fittings for Your Brewing Setup

-

10 Essential Tips for Choosing Stainless Steel Sanitary Fittings You Can't Ignore

-

2025 Top 5 Sanitary Connectors That Revolutionize Hygiene Standards