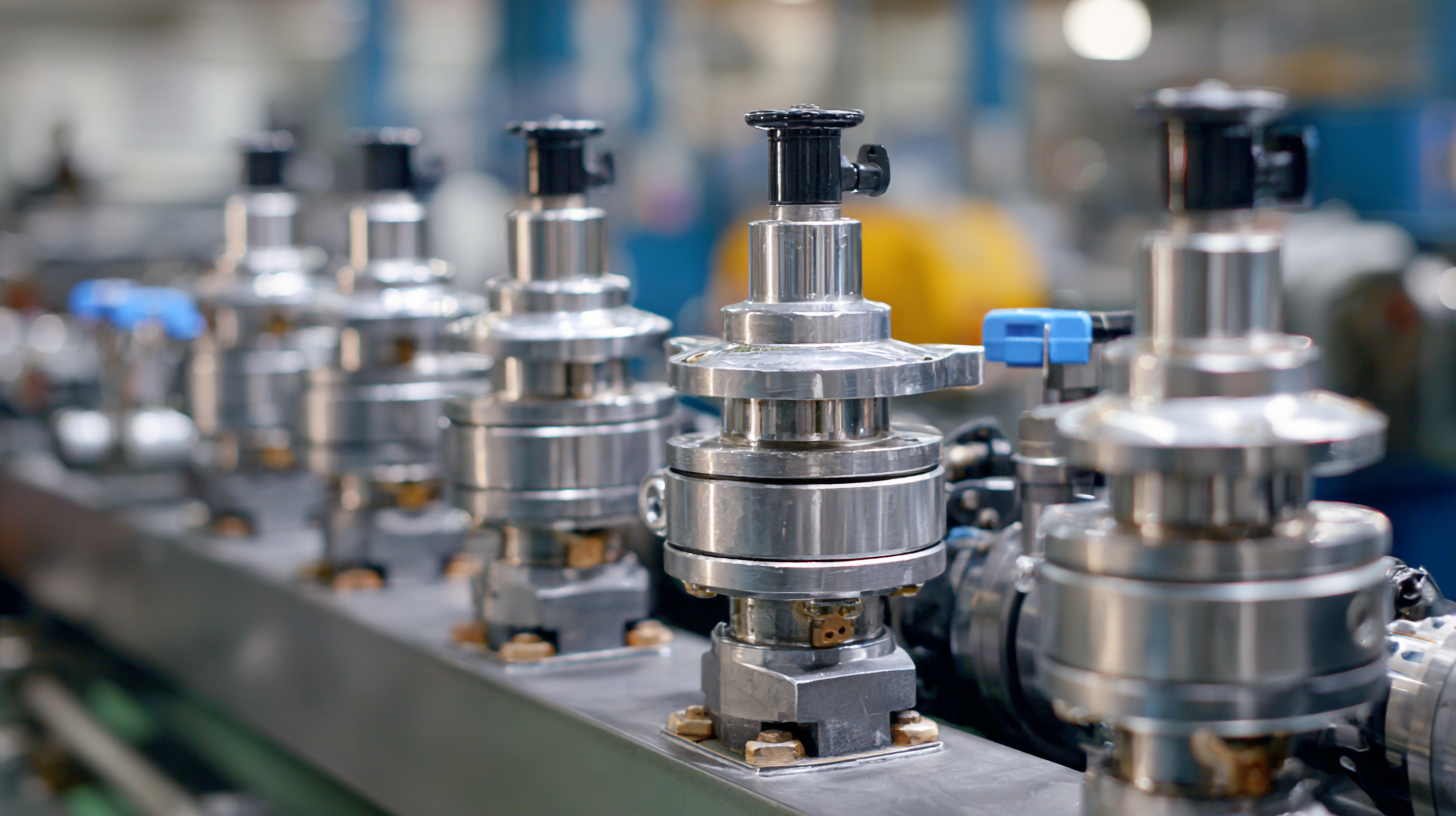

How to Select the Right Pump Valves for Your Industrial Applications

Selecting the right pump valves for industrial applications is a critical decision that can significantly impact the efficiency and reliability of fluid handling systems. With a myriad of options available in the market, understanding the specific requirements of your application is paramount. This article will guide you through the essential considerations to keep in mind when choosing pump valves, including factors such as flow rate, pressure ratings, material compatibility, and valve types.

By focusing on these key elements, you can ensure that the pump valves you select not only meet operational demands but also enhance the overall performance and longevity of your industrial systems. Whether you are dealing with corrosive fluids, high-temperature environments, or varying pressure conditions, making an informed decision about pump valves will ultimately optimize your processes and reduce unexpected downtime.

Factors to Consider When Choosing Pump Valves for Fluid Dynamics Optimization

When selecting pump valves for industrial applications, understanding fluid dynamics is essential to optimize performance and efficiency. Key factors to consider include the valve type, size, and material compatibility. According to a report by the Hydraulic Institute, the right selection can improve pump efficiency by up to 20%, thereby significantly reducing energy costs in long-term operations. For instance, using ball valves in high-flow applications can minimize pressure drops and maximize flow rates compared to traditional gate valves.

Material compatibility is another critical factor to consider, especially in environments where harsh chemicals are involved. A market research report by Mordor Intelligence reveals that the global industrial valve market, projected to reach $93 billion by 2025, underscores the importance of selecting materials that can withstand corrosive fluids without leading to premature valve failures. Careful analysis of factors such as temperature, pressure, and chemical composition will ensure that the chosen valves not only perform efficiently but also have a longer service life, reducing maintenance and replacement costs.

Fluid Dynamics Optimization: Pump Valve Selection Factors

Analyzing Pressure Drop and Flow Rate in Pump Valve Selection

When selecting pump valves for industrial applications, understanding the relationship between pressure drop and flow rate is crucial. A well-designed valve not only controls the flow of fluids but also minimizes energy losses, which directly affects the overall efficiency of the system. As in liquid rocket engines, where the transformation of chemical energy into kinetic energy results in thrust, the effective management of pressure and flow in pump systems ensures optimal performance in various applications, from manufacturing to chemical processing.

Pressure drop is a key factor influencing the selection of pump valves. It is essential to analyze how different valve designs can impact the flow rate while maintaining the desired performance levels. Valves with lower pressure drops can lead to energy savings and enhanced flow capacity, akin to how advanced liquid propulsion systems optimize thrust performance. By evaluating the specific requirements of an application and the fluid characteristics involved, engineers can choose the most suitable valves that not only meet flow demands but also reduce operational costs and enhance system reliability.

Material Compatibility: Assessing Corrosion Resistance in Industrial Environments

When selecting pump valves for industrial applications, one of the foremost considerations is material compatibility, especially in terms of corrosion resistance. According to a report by the National Association of Corrosion Engineers (NACE), corrosion causes approximately $276 billion in annual losses in the U.S. alone, underscoring the necessity of choosing materials that can withstand specific environmental conditions. For instance, stainless steel, with its high chromium content, offers excellent resistance to a wide variety of corrosive agents, making it a popular choice for industries that handle acidic or saline fluids.

However, not all stainless steels are created equal. Grade selection is crucial; for example, 316 stainless steel, which contains molybdenum, provides enhanced resistance to pitting and crevice corrosion compared to 304-grade stainless steel. Additionally, materials like PTFE (Teflon) and reinforced thermoplastics are increasingly being utilized due to their chemical inertness and low friction characteristics, which can extend the lifespan of pump valves in harsh environments. As reported by the Pump Systems Matter Initiative, using the right materials can improve system efficiency by 5-10%, enhancing not just performance but also reducing overall operational costs in industrial settings.

How to Select the Right Pump Valves for Your Industrial Applications - Material Compatibility: Assessing Corrosion Resistance in Industrial Environments

| Valve Material | Corrosion Resistance Rating | Temperature Range (°C) | Best Application |

|---|---|---|---|

| Stainless Steel | High | -50 to 400 | Chemical Processing |

| PVC | Moderate | -20 to 60 | Water Treatment |

| Cast Iron | Low | -10 to 150 | Wastewater Management |

| Bronze | Moderate | -20 to 150 | Marine Applications |

| PTFE | Excellent | -200 to 260 | Pharmaceuticals & Food |

Understanding Valve Types: Gate, Globe, Ball, and Check Valves for Different Applications

When selecting pump valves for industrial applications, it’s essential to understand the various types available to find the most suitable option for your specific needs.

Gate valves are primarily used for on-off services and allow for minimal pressure drop when fully opened. They are ideal for applications where the valve is either fully open or fully closed, making them a preferred choice in water and wastewater management systems.

Globe valves, on the other hand, are designed for throttling flow, allowing for better regulation of fluid dynamics. Their unique shape enables a higher pressure drop, making them suitable for applications that require precise flow control, such as in chemical processing. Additionally, ball valves provide quick and reliable shutoff capabilities and are suited for high-pressure and high-temperature applications. Lastly, check valves prevent backflow and are critical in ensuring the safety and efficiency of pump systems. Understanding these valve types helps in making informed decisions that enhance operational efficiency in industrial settings.

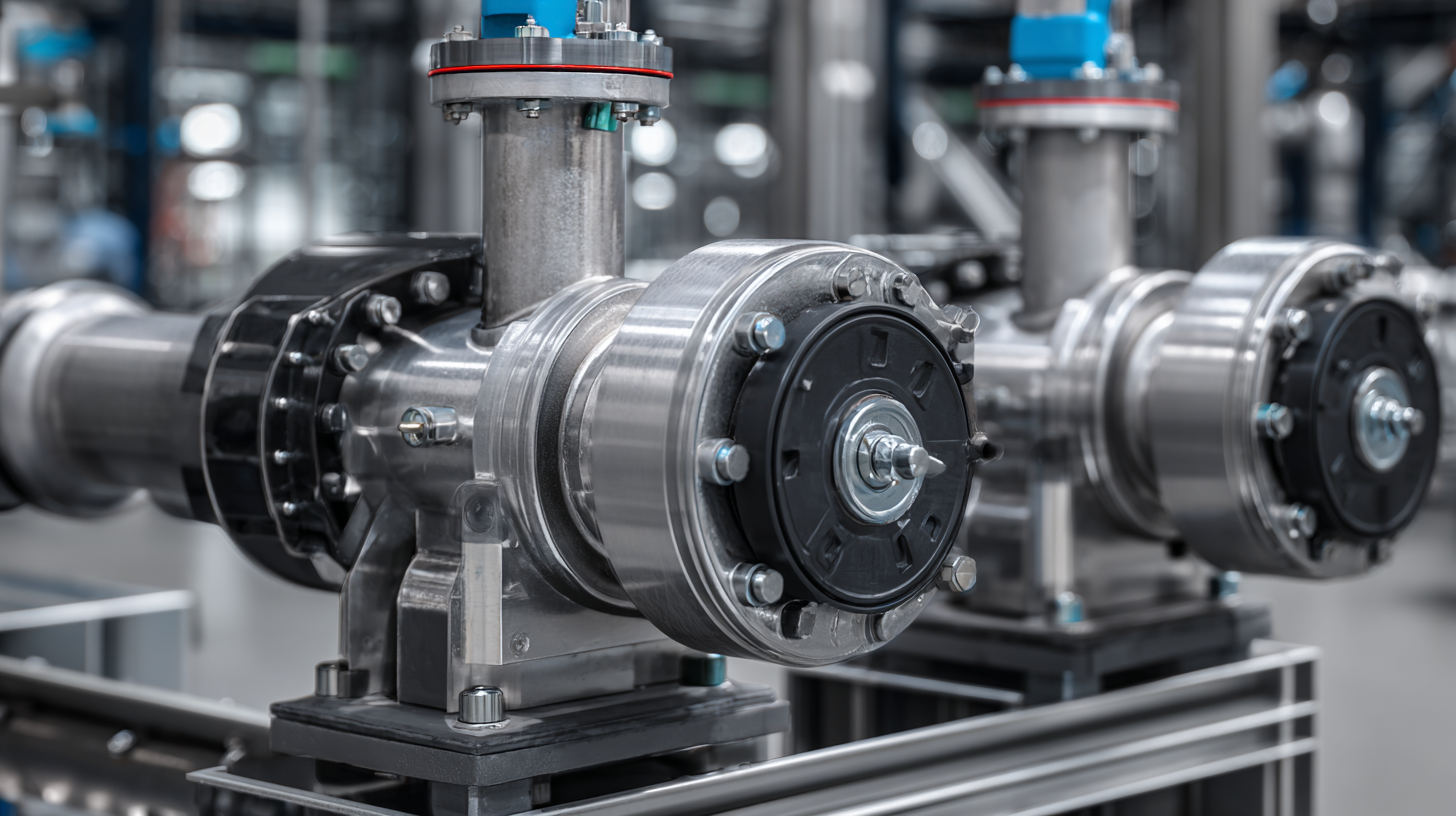

Key Performance Metrics: Evaluating Cv Values and Actuation Methods for Efficiency

When selecting the right pump valves for industrial applications, understanding key performance metrics is crucial. One of the primary metrics to evaluate is the Cv value, which measures the flow capacity of a valve. The higher the Cv, the greater the flow rate a valve can handle, making it essential for applications that require efficient and rapid fluid transfer. According to industry reports, valves with a Cv value exceeding 100 are considered high-capacity and suitable for demanding environments. Therefore, when assessing your options, opt for valves with a Cv that aligns with your required flow rates.

Additionally, actuation methods play a vital role in the efficiency of pump valves. Different applications may require pneumatic, electric, or hydraulic actuation, each offering distinct advantages. Pneumatic actuators, for instance, are often preferred for their rapid response and adaptability in harsh environments, while electric actuators can provide precise control for complex systems. Reports indicate that utilizing the appropriate actuation method can enhance overall system performance by up to 30%.

Tips: Always perform a thorough analysis of your system's requirements before making a selection. Consult with valve manufacturers to understand their testing data on Cv values and actuation methods, ensuring that you choose components that optimize efficiency and reliability.

Related Posts

-

How to Choose the Right Ball Valve for Your Application

-

Ultimate Sanitary Connectors Checklist for Ensuring Compliance and Efficiency

-

The Future of Diaphragm Valves Set to Transform Fluid Control Technologies

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

The Ultimate Guide to Choosing the Right Sanitary Fittings for Your Facility

-

How to Choose the Right Water Valves for Your Global Supply Needs