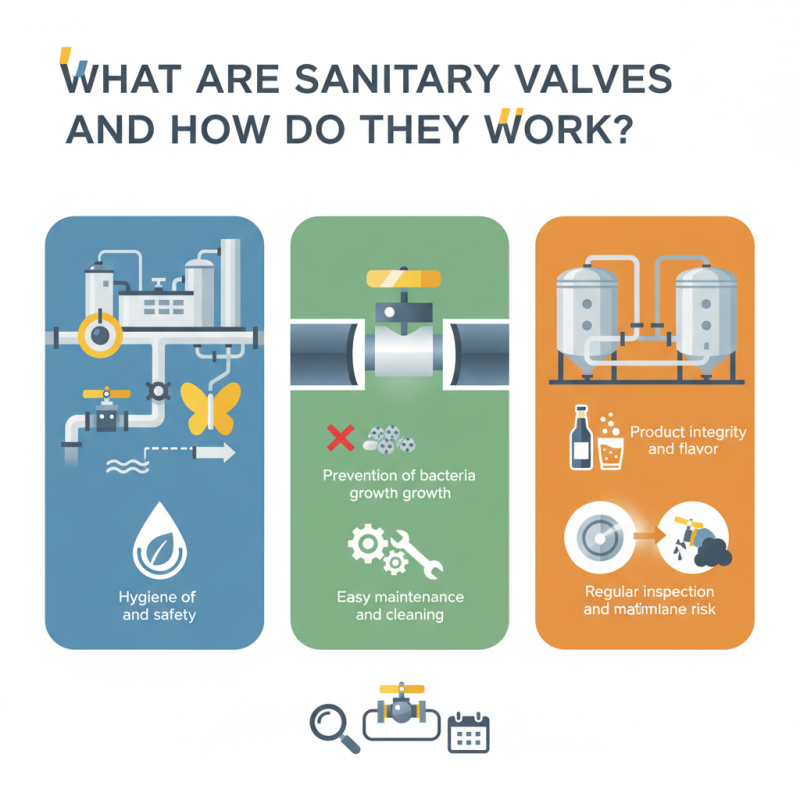

What are Sanitary Valves and How Do They Work?

Sanitary valves play a crucial role in various industries, particularly in food and beverage, pharmaceuticals, and biotechnology. These valves ensure that the fluid transport systems maintain hygiene and safety. They are designed to prevent contamination while allowing easy maintenance and cleaning.

Sanitary valves come in many types, including ball, butterfly, and check valves. Their design is specialized to create a smooth surface that reduces the risk of bacteria growth. In a brewery, for instance, the use of sanitary valves helps maintain product integrity and flavor.

However, not all sanitary valves are of equal quality. Some may have hidden flaws or poor sealing mechanisms. This can lead to contamination, which is a critical issue for manufacturers. It’s essential to regularly inspect and maintain these valves to ensure they function correctly. Understanding sanitary valves is vital for anyone involved in industries that prioritize hygiene and safety.

What Are Sanitary Valves?

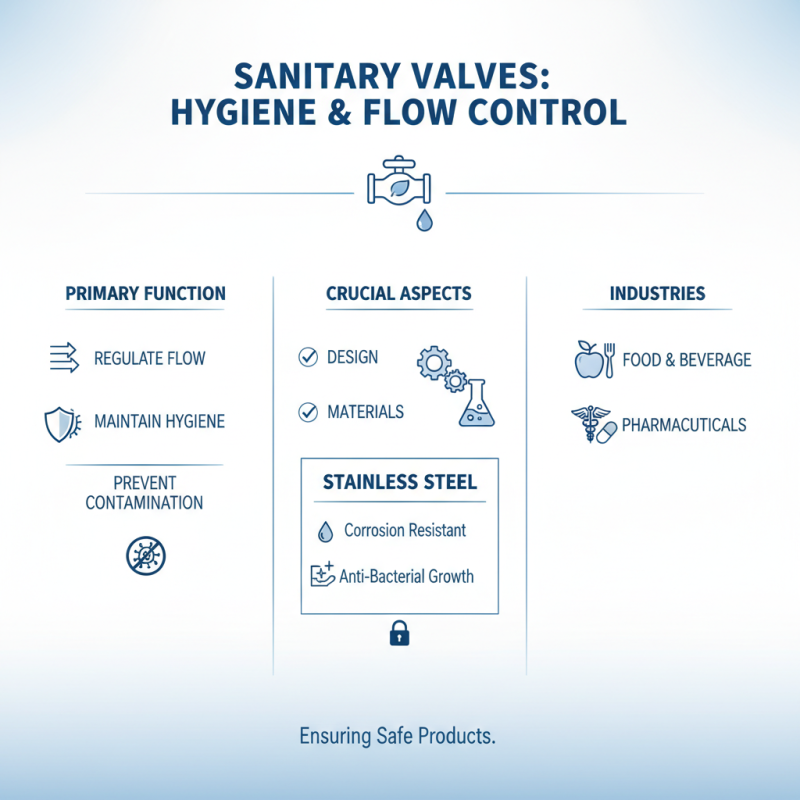

Sanitary valves are crucial components in industries like food and pharmaceuticals. They ensure the safety and integrity of products. These valves control the flow of liquids and gases. The design minimizes contamination risks. This is vital in environments requiring strict hygiene standards.

These valves come in various types, including ball, butterfly, and check valves. Each type serves a specific purpose. Ball valves offer quick shut-off, while butterfly valves are efficient in larger pipelines. Sanitary valves often feature smooth surfaces to avoid residue buildup. Materials like stainless steel are common. They are easy to clean and maintain.

However, not all designs are perfect. Complex systems can lead to maintenance challenges. If not properly cleaned, bacteria can thrive. Operators must regularly inspect valves. It’s essential to train staff on best practices. Care and attention make a significant difference in outcomes.

Key Features of Sanitary Valves

Sanitary valves play a crucial role in various industries, especially in food and pharmaceuticals. Their design prioritizes hygiene and efficiency. They are constructed from stainless steel, providing corrosion resistance. This material choice is vital since it meets strict cleanliness standards.

Key features include quick-release mechanisms. These allow for easy access during cleaning. In fact, studies show that around 30% of contamination issues arise from poorly maintained valves. The ability to efficiently sanitize these components can significantly reduce such risks. Additionally, many sanitary valves include smooth interiors to minimize residue buildup. This design choice is supported by industry reports indicating a 15% reduction in microbial growth when using such valves.

Another notable feature is their versatility. They can handle various pressures and temperatures. However, not all designs are suitable for every application. Some may require specific configurations to function optimally. The selection process can be challenging, as a mismatch may lead to operational failures. It's essential to understand the specific requirements of your system. Choosing the right valve, therefore, involves careful consideration of all these factors.

Types of Sanitary Valves and Their Applications

Sanitary valves are crucial in various industries, especially food, beverage, and pharmaceuticals. These valves ensure hygienic processing. They prevent contamination and ensure quality. Different types of sanitary valves cater to specific needs.

Butterfly valves are common in fluid systems. Their lightweight design makes them efficient. They help control flow rates easily. According to industry reports, their usage has increased by 15% in the last five years. Another type is the diaphragm valve. This valve is ideal for applications needing a clean environment. It minimizes the risk of contamination effectively. Users often appreciate the simple design and ease of maintenance.

However, selecting the right sanitary valve isn't always straightforward. Factors such as material compatibility and pressure ratings come into play. Reports highlight that nearly 30% of valve failures occur during installation due to improper selections. This shows that training and knowledge are vital. Addressing these challenges can improve operational efficiency significantly.

The Mechanism of Action in Sanitary Valves

Sanitary valves are essential in industries like food and pharmaceuticals. Their primary function is to regulate flow while maintaining hygiene. They prevent contamination, ensuring products remain safe. The design and materials are crucial for achieving this goal. Stainless steel is often the material of choice. It resists corrosion and bacteria growth.

The mechanism of action in sanitary valves involves various components. When the valve is operated, a disc, ball, or diaphragm moves to open or close the flow path. This movement can be manual or automated. Pneumatic systems often control the opening and closing, providing precision. However, maintenance is vital. If not regularly checked, they can malfunction. This could lead to leaks or contamination, raising significant concerns.

Understanding how these valves operate helps in ensuring effectiveness. Each component has a role to play. For instance, seals must fit perfectly to prevent leaks. Any imperfection can compromise the entire system. Regular inspections can identify these flaws. It’s crucial to address them promptly. Ignoring minor issues can lead to bigger problems down the line.

Importance of Sanitary Valves in Industrial Processes

Sanitary valves play a crucial role in various industrial processes, particularly in food and beverage production. These valves ensure that the flow of liquids is controlled without contamination. The need for cleanliness is paramount in these industries. Each valve must meet strict hygiene standards. They are designed to minimize fluid retention and facilitate easy cleaning.

In pharmaceuticals, sanitary valves help maintain sterile conditions. They prevent microbial growth, which can jeopardize product safety. The selection of the right valve type is not always straightforward. Misunderstandings can occur about their functionality and limitations. Some may oversimplify their importance, leading to potential risks. Understanding these components deeply is essential for ensuring safety.

Moreover, incorrect installation can lead to leaks or failure during operation. It is vital to prioritize proper training for workers. Without it, even the best equipment can be rendered ineffective. Reliable performance is only possible through careful attention to every detail. For industrial processes, overlooking any aspect of sanitary valves can have significant consequences.

What are Sanitary Valves and How Do They Work? - Importance of Sanitary Valves in Industrial Processes

| Dimension | Description | Importance |

|---|---|---|

| Material | Typically made from stainless steel or plastic for resistance to corrosion and contamination. | Ensures high cleanliness standards in food and beverage processing. |

| Size | Comes in various sizes to meet different flow requirements. | Facilitates proper flow rates and efficiency in processes. |

| Type | Includes butterfly, ball, and diaphragm valves. | Different types suit various applications, impacting performance and maintenance. |

| Functionality | Controls flow of liquids and gases in a sanitary manner. | Prevents contamination and maintains product integrity. |

| Standards Compliance | Must comply with regulations such as FDA and 3A Sanitary Standards. | Ensures safety and quality of processed products. |

Related Posts

-

The Ultimate Guide to Choosing Eco-Friendly Water Fittings for Sustainable Living

-

2026 Guide: How to Choose the Right Sanitary Ball Valves for Your Needs

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

Understanding Valve Fittings: Key Trends and Innovations Driving Industry Growth in 2023

-

How to Choose the Best Stainless Steel Ball Valves for Your Needs

-

Essential Brewery Fittings Every Craft Brewer Must Have for Optimal Production