What is a sanitary diaphragm valve and how does it work?

Sanitary diaphragm valves play a critical role in various industries. They ensure hygiene and safety in systems like food processing and pharmaceuticals. These valves control the flow of fluids while preventing contamination.

The design of a sanitary diaphragm valve is unique. It utilizes a flexible diaphragm to open and close the flow path. This mechanism creates a tight seal, preventing any leakage. Moreover, the materials used are often resistant to corrosion and easy to clean.

However, users must be aware of potential challenges. Maintaining the diaphragm can be tricky. Over time, wear and tear might raise concerns. Longevity depends on proper installation and routine checks. Understanding these factors is essential for effective operation. Ultimately, a sanitary diaphragm valve is a vital component for maintaining product integrity.

What is a Sanitary Diaphragm Valve? Definition and Purpose Explained

Sanitary diaphragm valves are crucial in industries that require strict hygiene standards. These valves are designed to control the flow of liquids, often in food, pharmaceuticals, or biotech sectors. The defining feature is the diaphragm, which acts as a barrier between the media and the valve’s mechanics, preventing contamination. Reports indicate that the global sanitary valve market is expected to grow by over 5% annually, reflecting the rising demand for hygienic processing solutions.

The primary purpose of a sanitary diaphragm valve is to maintain cleanliness while allowing for precise flow control. With a simple design, these valves minimize dead zones where bacteria could thrive. Most sanitary diaphragm valves operate pneumatically or manually. This flexibility allows companies to automate processes or use manual controls based on their needs. However, maintenance remains a challenge. Regular inspections are necessary to ensure the diaphragm remains intact, as wear can lead to leaks.

In practical applications, using sanitary diaphragm valves can significantly reduce product loss and contamination. Yet, the initial setup can be complex, requiring proper training and understanding of the system. Some industries report difficulties in finding skilled professionals who can maintain these systems. This gap highlights the need for better education and awareness around the importance of sanitary equipment.

Understanding the Flow Characteristics of Sanitary Diaphragm Valves

This bar chart illustrates the flow characteristics of sanitary diaphragm valves, displaying flow rate, pressure drop, and temperature tolerance. Understanding these metrics is essential for evaluating valve performance in sanitary applications.

Key Components of a Sanitary Diaphragm Valve: Materials and Design

Sanitary diaphragm valves play an essential role in various industries. They are designed to control the flow of liquids and gases while maintaining hygiene. The key components of these valves determine their efficiency and reliability.

The body of the valve is typically made from stainless steel. This choice ensures durability and resistance to corrosion. The diaphragm itself is often crafted from elastomer or Teflon, which provides excellent sealing. A well-designed diaphragm minimizes contamination risks.

The operators of these valves vary but often include manual, pneumatic, or electric systems. Each method has its benefits and drawbacks. Part of the design also focuses on ease of cleaning, which is paramount in sanitary applications. The smooth surfaces reduce the likelihood of residue buildup.

Despite the high-quality materials, maintaining the optimal performance of these valves requires regular inspection. Sometimes, issues like leaks can occur if the diaphragm wears out. It's important to conduct thorough checks to ensure they function properly. Balancing the materials with their intended use is crucial. Inadequate design can lead to operational challenges.

How Sanitary Diaphragm Valves Operate: Mechanism and Functionality

Sanitary diaphragm valves are essential in industries requiring clean and sterile processes. They feature a flexible diaphragm that controls flow by moving up and down. This unique design prevents contamination, making them ideal for food, beverage, and pharmaceutical applications.

The operation is straightforward. When the actuator moves, it pushes or pulls the diaphragm. This action either opens or closes the valve. The diaphragm creates a seal against the valve body, ensuring no media leaks occur. Regular maintenance is crucial for optimal performance. Inspect the diaphragm for wear and tear. Replace if necessary to avoid unexpected failures.

Tips:

Always ensure the valve is compatible with the media. Check for operational pressure limits. Proper installation is also key to functionality. A misaligned valve may lead to leaks. Regular checks can save time and resources in the long run.

Applications of Sanitary Diaphragm Valves in the Food and Beverage Industry

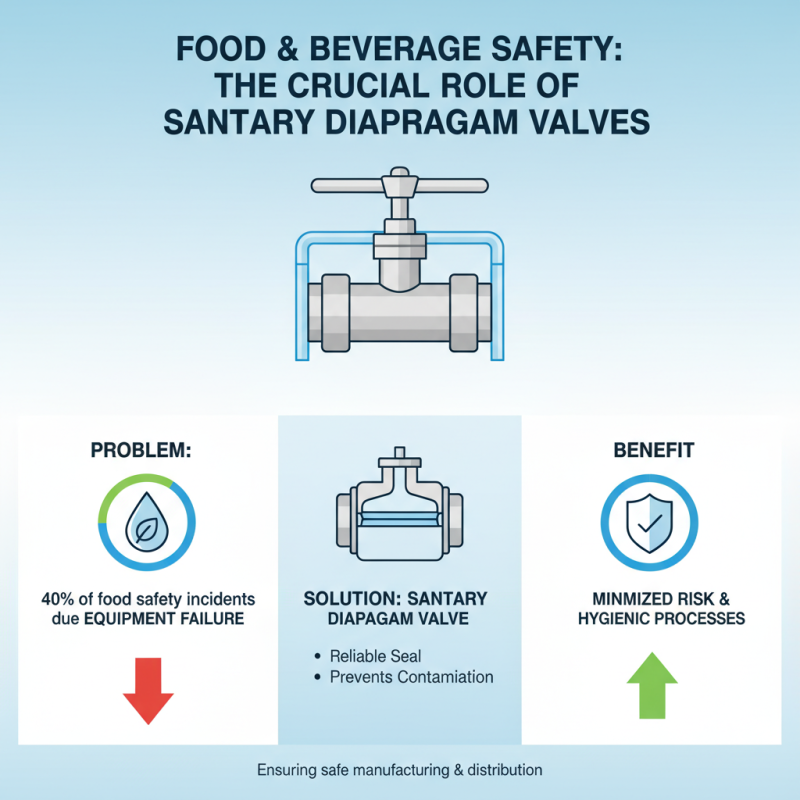

In the food and beverage industry, sanitary diaphragm valves play a crucial role. These valves ensure safe and hygienic processes in manufacturing and distribution. According to industry reports, nearly 40% of food safety incidents stem from equipment failure. A sanitary diaphragm valve minimizes this risk by providing a reliable seal and preventing contamination.

These valves are often used in applications such as dairy production and brewing. They can handle varying pressures and temperatures, adding versatility. For instance, dairy companies often face challenges with bacteria. A leak-free operation in sanitary diaphragm valves reduces this issue significantly. However, maintenance can be a concern. Improper handling may lead to wear and tear, affecting functionality.

The design of these valves allows for easy cleaning and inspection. Yet, if not properly maintained, they can create hidden risks. Equipment that is not regularly checked may compromise food safety standards. As awareness of food safety grows, industries are increasingly adopting these valves to enhance their operations. However, continuous oversight is crucial. Ensuring that these components function correctly can prevent costly recalls or safety breaches.

Benefits of Using Sanitary Diaphragm Valves for Hygiene and Safety Standards

Sanitary diaphragm valves are essential in maintaining hygiene standards in sensitive industries like food processing and pharmaceuticals. These valves feature a flexible diaphragm that controls flow, minimizing contamination risks. They excel in handling viscous and corrosive materials while ensuring reliable sealing.

The benefits of using these valves extend to improved safety. A report from the International Society for Pharmaceutical Engineering states that 80% of contamination issues stem from improper valve operation. This highlights the importance of choosing the right valve for critical applications. Sanitary diaphragm valves mitigate these risks effectively by eliminating dead zones where contaminants can accumulate.

**Tip:** Regular maintenance and inspection are vital. Look for wear on the diaphragm and check for leaks.

These valves can be more challenging to clean than traditional options. The immediate need for thorough cleaning raises costs and downtime, which can be a concern.

**Tip:** Implement a strict cleaning schedule to ensure optimal performance. This will help you avoid potential contamination and safety issues.

Investing in sanitary diaphragm valves enhances overall safety and hygiene. Their design promotes efficient flow control while meeting stringent industry standards. Ultimately, they are a valuable addition to any system demanding high purity levels.

Related Posts

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

How to Choose the Right Sanitary Ball Valves for Your Applications

-

2025 Guide: How to Choose the Right Sanitary Ball Valves for Your System

-

Ultimate Sanitary Connectors Checklist for Ensuring Compliance and Efficiency