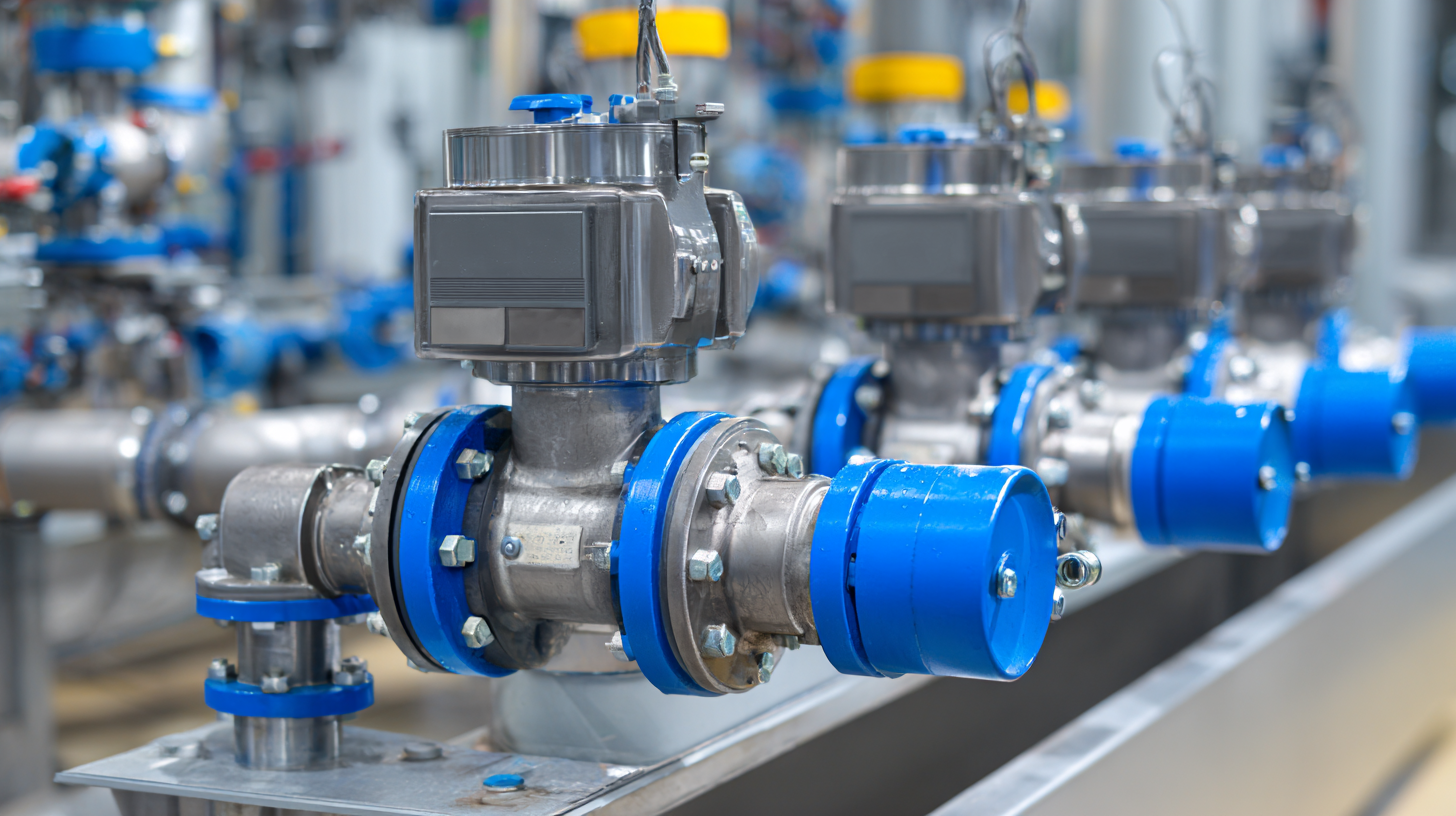

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries

In the realm of modern industries, the efficiency of processes is paramount, particularly in sectors requiring strict hygiene standards such as food and beverage, pharmaceuticals, and biotechnology. According to a recent report by MarketsandMarkets, the smart sanitary valves market is projected to reach USD 1.45 billion by 2026, growing at a CAGR of 12.3%. This surge can be attributed to the escalating demand for automation and precision in process control, where sanitary valves play a critical role.

These advanced systems not only enhance operational efficiency but also ensure compliance with stringent regulatory standards, thereby revolutionizing how industries manage fluids and minimize contamination risks. As organizations strive for enhanced productivity and safety, the integration of smart sanitary valves becomes an indispensable aspect of modern process optimization strategies.

Transforming Industrial Workflows with Intelligent Sanitary Valve Solutions

In the quest for enhancing industrial workflows, intelligent sanitary valve solutions have emerged as game-changers. These smart valves seamlessly integrate with modern automation systems, enabling precise control over fluid dynamics while ensuring hygiene standards. By adopting advanced sensor technologies and data analytics, industries can monitor real-time performance and make data-driven decisions that streamline operations. This capability not only minimizes waste but also optimizes maintenance schedules, ultimately contributing to a more efficient production environment.

Furthermore, the adaptability of intelligent sanitary valves across various applications—from food and beverage to pharmaceuticals—demonstrates their versatility in addressing specific industry needs. With their programmable features, these valves facilitate rapid adjustments during production changes, reducing downtime and enhancing overall productivity. As industries increasingly focus on sustainability and efficiency, the implementation of smart sanitary valve solutions is proving crucial in transforming traditional workflows into agile, responsive systems that meet the demands of modern manufacturing.

Revolutionizing Process Efficiency with Smart Sanitary Valves

This chart illustrates the significant increase in process efficiency before and after the implementation of smart sanitary valves in modern industries. The data shows an improvement from 65% to 90%, highlighting the transformative impact of intelligent valve solutions on industrial workflows.

Integrating Digital Technology for Enhanced Process Management in Industries

In modern industries, integrating digital technology into process management has become essential for enhancing operational efficiency. The digital transformation landscape reveals that organizations striving for success are increasingly adopting smart sanitary valves equipped with digital capabilities. According to recent reports, businesses that have embraced digital technologies have seen process enhancements exceeding 30%, significantly shortening time-to-market and improving product quality. Leveraging real-time data analytics and IoT connectivity, smart sanitary valves not only optimize flow control but also facilitate predictive maintenance, reducing unexpected downtime and associated costs.

Moreover, the integration of lean management principles in conjunction with digital transformation is paramount. A study shows that companies adhering to lean methodologies alongside technological integration can improve their manufacturing efficiency by up to 25%. The evolution towards smart sanitary valves exemplifies this trend, integrating features that allow for seamless data exchange across systems. This connectivity fosters a more agile and responsive manufacturing environment, enabling industries to adapt swiftly to market demands while ensuring compliance with the highest safety standards. In an era defined by rapid digital acceleration, the convergence of these technological advancements marks a revolutionary step forward in industrial process management.

Key Advantages of Smart Sanitary Valves in Operational Efficiency

Smart sanitary valves are transforming modern industries by enhancing operational efficiency through automation and intelligent control. One of the key advantages of these valves is their ability to provide real-time monitoring and data analytics. This capability allows operators to optimize processes by identifying bottlenecks, reducing waste, and ensuring consistent product quality. The integration of smart technology facilitates predictive maintenance, minimizing downtime and extending the lifespan of equipment.

Another significant benefit is the improved safety and compliance with industry standards. Smart sanitary valves are designed with built-in sensors and feedback mechanisms that allow for precise control over fluid dynamics and pressure. This ensures that processes run within safety parameters, effectively reducing the risk of contamination and accidents. Furthermore, remote control options enable operators to manage systems from anywhere, increasing flexibility and response times in critical situations. In summary, smart sanitary valves not only streamline processes but also foster a safer and more productive working environment in modern industries.

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries - Key Advantages of Smart Sanitary Valves in Operational Efficiency

| Feature | Description | Impact on Efficiency | Key Industries |

|---|---|---|---|

| Automated Control | Remote monitoring and control of valve operations | Reduces manual intervention, increases responsiveness | Food and Beverage, Pharmaceuticals |

| Data Analytics | Real-time data collection for operational insights | Enables predictive maintenance and optimization | Chemical Processing, Water Treatment |

| Improved Hygiene | Seamless design to minimize contamination risks | Enhances safety and product quality | Pharmaceuticals, Biotech |

| Energy Efficiency | Optimized flow control to reduce excess energy use | Lowers operational costs and carbon footprint | Food and Beverage, HVAC |

| Enhanced Durability | Designed for long-lasting performance under stress | Reduced downtime and maintenance frequency | Oil and Gas, Water Utilities |

Real-Time Monitoring and Control: The Future of Sanitary Valves

The advent of smart sanitary valves is poised to transform process efficiency in modern industries, with real-time monitoring and control emerging as crucial components of this evolution. In sectors such as pharmaceuticals and food processing, the integration of IoT (Internet of Things) technology into sanitary valves offers unprecedented visibility into operational processes. According to a recent report by MarketsandMarkets, the industrial IoT market is expected to reach $110.6 billion by 2025, highlighting the increasing demand for connected devices that allow for immediate data collection and analysis.

These smart valves enable continuous monitoring of critical parameters such as flow rates, pressure, and temperature, allowing operators to respond to anomalies instantaneously. For example, a study by Frost & Sullivan indicates that implementations of real-time monitoring systems can enhance process efficiency by up to 30%, significantly reducing waste and downtime. Such capabilities not only ensure compliance with regulatory standards but also enhance product quality, making them indispensable in industries that prioritize hygiene and safety. As organizations recognize the potential for cost savings and improved operational workflows, the future of sanitary valves lies in their ability to provide actionable insights in real time.

Case Studies: Successful Implementation of Smart Valves in Various Sectors

The deployment of smart sanitary valves is making significant strides across various sectors, showcasing successful implementations that have revolutionized process efficiency. In the water distribution industry, for example, the integration of the Internet of Things (IoT) solutions has enabled precise management of non-revenue water (NRW). This not only improves water conservation efforts but also enhances operational transparency and accountability. Intelligent valves equipped with real-time monitoring capabilities allow operators to quickly respond to leaks or anomalies, drastically minimizing wastage and optimizing resource allocation.

Moreover, the automotive manufacturing sector has benefited from the implementation of smart valves within quality monitoring frameworks. By harnessing machine learning technologies, companies can continually analyze process data and maintain high manufacturing standards. This real-world application demonstrates how smart valves contribute to a holistic approach in quality management, striking a balance between efficiency and quality assurance. Similarly, in the oil and gas industry, smart valves help streamline operations powered by sustainable energy solutions, reflecting the ongoing transformation toward more environmentally conscious practices.

Related Posts

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

How to Select the Right Pump Valves for Your Industrial Applications

-

The Ultimate Guide to Understanding and Choosing Butterfly Valves for Your Industrial Needs

-

7 Essential Insights about Steel Fittings for Optimal Performance