Essential Guide to Choosing the Right Valve Fittings for Optimal Performance

In the ever-evolving industrial landscape, the importance of selecting the right valve fittings cannot be overstated, as they play a crucial role in ensuring optimal system performance and efficiency. According to a report by MarketsandMarkets, the global valve fittings market is projected to reach USD 80 billion by 2025, with a compounded annual growth rate (CAGR) of 6.4%. This underscores the growing recognition of how vital it is to choose appropriate valve fittings that minimize leaks, prevent corrosion, and enhance operational safety. Moreover, the American Society of Mechanical Engineers (ASME) emphasizes that improper fittings can lead to up to 30% decrease in energy efficiency, highlighting the financial and operational impacts of poor choices. As industries seek to optimize their processes, understanding the nuances of valve fittings selection becomes paramount, and this guide aims to provide essential tips and insights to help achieve peak performance in various applications.

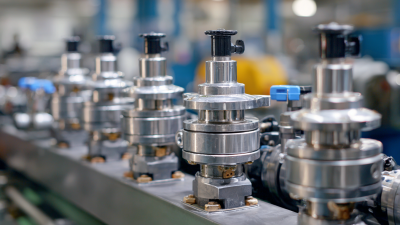

Understanding Valve Types: A Comprehensive Overview of Common Valve Configurations

When selecting valve fittings, understanding the various types of valves is crucial for optimal performance. Each valve configuration serves a specific purpose, from controlling flow rates to managing pressure within a system. Common types include

globe valves,

gate valves,

ball valves,

and

butterfly valves.

Globe valves are excellent for throttling, while gate valves are ideal for on/off control, providing minimal resistance when fully opened. Ball valves offer durability and quick operation, while butterfly valves are lightweight and suitable for large volume flows.

Tips: When evaluating valve types for your application, consider the medium being controlled, the pressure and temperature ranges, and the required flow characteristics. This ensures a fitting match between the valve type and system requirements.

Another key consideration is the material of the valve itself. Common materials include

brass,

stainless steel,

and

plastic, each with unique advantages. Stainless steel is ideal for corrosive environments, while plastic valves are lightweight and cost-effective. Understanding these factors will lead to better decision-making in valve selection.

Tips: Always check the compatibility of valve materials with the fluids they will handle. Avoiding chemical reactions or wear is vital to the longevity and functionality of your valve fittings.

Key Performance Metrics: Evaluating Flow Rate, Pressure Drop, and Leak Rates

When selecting valve fittings, understanding key performance metrics is crucial for ensuring optimal performance. Evaluating flow rate is essential, as it directly impacts how efficiently a system operates. A higher flow rate generally indicates better system efficiency; however, it must be balanced with other factors like pressure and application requirements. Accurate assessment of the flow rate not only aids in selecting the right fitting but also in matching it to the overall system design.

Another critical metric is pressure drop, which measures the decrease in pressure as fluid flows through the valve. A significant pressure drop can lead to energy losses and affect process efficiency. It is vital to choose fittings that minimize pressure drop while still achieving the desired flow characteristics. Lastly, evaluating leak rates ensures system integrity and reliability. Minimizing leakage not only conserves resources but also enhances safety.

Therefore, a holistic approach to analyzing these performance metrics helps in selecting the most suitable valve fittings, leading to improved system performance and longevity.

Materials Matter: Selecting the Right Valve Fittings Based on Application and Environment

When selecting valve fittings, understanding the significance of material choice based on the specific application and environment is paramount. Different materials exhibit distinct properties that can affect the longevity and performance of valve systems. For instance, materials such as stainless steel and PVC are often preferred for their corrosion resistance and durability, especially in marine applications where exposure to saltwater can significantly impair system integrity. Reports indicate that nearly 70% of valve failures are attributed to material corrosion, highlighting the necessity of choosing the right material to optimize performance.

Furthermore, valve fittings must be compatible not only with the fluids they will handle but also with the pressures and temperatures of their operating environments. Industry studies show that the right selection can improve energy efficiency by as much as 15%, reducing both operational costs and environmental impact. As illustrated in recent exhibitions, leading companies are showcasing advanced valve technology tailored for energy efficiency, underlining the trend towards sustainability in sectors like the marine industry. Investing in the correct materials and valve fittings ensures reliability and performance, leading to enhanced operational efficiency in diverse applications.

Essential Guide to Choosing the Right Valve Fittings for Optimal Performance

This chart illustrates the performance characteristics of various valve fitting materials under different environmental conditions. Understanding the strengths and weaknesses of each material can help in making the right selection for specific applications.

Installation Considerations: Best Practices for Ensuring Optimal Performance and Longevity

When it comes to installing valve fittings, paying attention to best practices is crucial for achieving optimal performance and longevity of the system. According to a report by the American Society of Mechanical Engineers (ASME), improper installation can lead to a significant increase in maintenance costs, with estimates suggesting that up to 70% of valve failures are a result of installation errors. Therefore, ensuring that the fittings are compatible with the fluid type and operating conditions is essential.

Tip: Always verify the specifications of valve fittings against the system requirements, including pressure ratings and material compatibility. This will help in avoiding premature wear and failures.

Furthermore, attention must be given to proper torque settings during installation. A study published in the Journal of Pipeline Systems Engineering and Practice indicates that inconsistent bolt torquing can lead to leaks, reducing system efficiency. It's advisable to use a calibrated torque wrench and follow the manufacturer's recommendations to establish proper preload.

Tip: Implement regular maintenance checks to monitor the performance of valve fittings. This can preemptively address issues like leaks, which can otherwise compromise system integrity.

Maintenance Guidelines: Ensuring Reliability and Efficiency Through Regular Inspections and Upkeep

Regular inspection and maintenance are crucial for ensuring the reliability and efficiency of valve fittings in industrial applications. Just as educational frameworks emphasize the need for regular evaluations to maintain quality standards, the same principle applies to valve systems which, when neglected, can lead to performance inefficiencies and costly repairs. Scheduled inspections allow for the early detection of potential issues, such as leaks or wear and tear, thus ensuring that the valve fittings function optimally in various conditions.

Furthermore, maintenance guidelines should include a routine check of the fittings for corrosion, physical damage, and alignment. Proper upkeep often involves cleaning and testing the valves to ensure they operate as intended. Additionally, employing advanced technologies such as autonomous underwater robots can significantly enhance inspection efforts, especially for hard-to-reach industrial infrastructure. By adhering to these maintenance practices, industries can prolong the lifespan of their systems and maintain effective operational performance, echoing the importance of diligence in any inspection framework.

Related Posts

-

How to Choose the Right Fittings and Valves for Your Industrial Needs

-

Top Strategies for Enhancing Performance with Fittings Valves

-

Understanding the Types of Tubing Fittings for Optimal Performance

-

6 Tips to Choose the Right Sanitary Connectors for Optimal Hygiene Compliance

-

How to Select the Right Pump Valves for Your Industrial Applications

-

7 Essential Tips for Choosing the Right Sanitary Fittings for Your Project