Top 10 Essential Tubing Fittings for Your Next Project

In the realm of fluid dynamics and assembly, the choice of appropriate tubing fittings is crucial for ensuring optimal performance and reliability of systems. According to the International Fluid Power Society, tubing fittings contribute significantly to system efficiency, with an estimated 30% of downtime in hydraulic systems being attributed to improper fitting selection and installation. This highlights the necessity for engineers and project managers to select the right components that not only meet the project specifications but also adhere to industry standards.

With the diverse applications of tubing fittings across various sectors, such as automotive, aerospace, and manufacturing, it becomes imperative to understand the critical features and advantages that each type of fitting offers. A recent report by the ScienceDirect notes that the global market for fluid power components, which includes tubing fittings, is projected to surpass $65 billion by 2025, driven by advancements in technology and increasing demands for automation in production processes. Thus, selecting the top tubing fittings tailored to specific project needs can significantly influence efficiency, reduce leaks, and enhance safety across various applications.

In this article, we will delve into the “Top 10 Essential Tubing Fittings for Your Next Project,” showcasing their unique benefits and applications. By providing insights into these pivotal components, we aim to equip industry professionals with the knowledge needed to make informed decisions while optimizing system performance and longevity.

Key Factors to Consider When Selecting Tubing Fittings

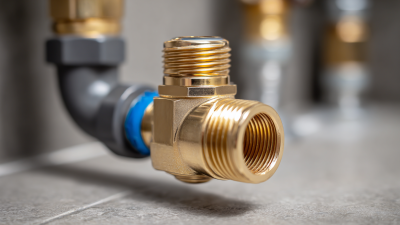

When selecting tubing fittings for your next project, it is crucial to consider several key factors that can impact the performance and reliability of your system. First, assess the material compatibility of the fittings with the fluids they will carry. Different materials, such as stainless steel, brass, or plastic, have varying chemical resistances which can affect their longevity and safety in applications involving corrosive substances.

Another important aspect to consider is the fitting size and pressure rating. Ensuring that you choose fittings that match the dimensions and pressure requirements of your tubing is vital to maintain a secure and leak-free connection. Additionally, pay attention to the fitting design, as some configurations provide better flow characteristics or ease of installation depending on the specific needs of your project. By taking these factors into account, you can ensure a successful implementation of your tubing system and prevent future complications.

Innovative Materials for Enhanced Performance in Tubing Fittings

In the realm of tubing fittings, innovation in materials plays a crucial role in enhancing performance and durability. Recent industry reports indicate that the global tubing fittings market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2022 to 2028. This growth is largely attributed to advancements in manufacturing techniques and materials, such as high-performance polymers and corrosion-resistant alloys. These materials offer superior resistance to environmental stressors, which is essential for applications in challenging conditions, such as oil and gas, chemical processing, and pharmaceuticals.

Moreover, the introduction of composite materials is transforming the way engineers approach tubing fitting designs. According to a comprehensive analysis by the Material Science Institute, fittings made from advanced composites not only reduce weight by up to 40% but also significantly improve chemical resistance and pressure ratings. As industries demand higher efficiency and reduced downtime, the shift towards innovative materials is becoming paramount. By selecting tubing fittings made from these cutting-edge materials, professionals can ensure longer-lasting performance and greater reliability in their projects.

Comparative Analysis of Top 10 Tubing Fitting Brands in 2025

In 2025, the tubing fittings market is expected to witness notable transformations driven by advancements in material technology and the demand for customized solutions across various industries. A recent industry report predicts that the global tubing fittings market will grow at a CAGR of 5.2%, reaching an estimated value of $6.5 billion by 2028. Major players such as Parker Hannifin, Swagelok, and Eaton continue to dominate this competitive landscape, offering a range of products that meet stringent standards.

When comparing top brands in tubing fittings, it is essential to consider performance metrics such as pressure ratings and compatibility with various tube materials. According to a survey conducted by the Fluid Power Journal, 67% of industry professionals prioritize durability and corrosion resistance when selecting tubing fittings. This highlights the significance of brands that invest in innovative materials like stainless steel, brass, and advanced polymers that can withstand harsh environments.

**Tips:** When choosing tubing fittings for your project, ensure you assess the specific application requirements. For high-pressure settings, select fittings that exceed the average workload by at least 25% to ensure reliability. Additionally, always cross-check the compatibility of your fittings with the tubing material to prevent leaks and failures.

Safety Standards and Testing Procedures for Tubing Fittings

When it comes to tubing fittings for various projects, adhering to safety standards is paramount. Tubing misconnections can lead to severe consequences, particularly in medical settings. It’s crucial to implement industry-wide safety standards such as the adoption of specific enteral feeding connectors designed to prevent inappropriate connections. These innovations are aimed at securing the safety of tube-fed patients, ensuring both caregivers and patients can trust the equipment being used.

Tips: Always verify that the tubing fittings you select comply with established safety regulations. Inspect your connections regularly to avoid any potential hazards, and stay updated with the latest industry standards to ensure your equipment remains reliable and safe. When using plastic pipes, be aware of the materials involved; scrutiny over PVC safety has raised significant red flags regarding its use.

Furthermore, understanding the fundamental requirements of safety standards, such as those outlined in the 3-A Sanitary Standards, can enhance your project's integrity. By ensuring that tubing fittings are nontoxic, cleanable, and inspectable, you not only meet regulatory expectations but also improve the overall safety of your installation. Regular testing and adherence to the latest standards are key to maintaining both safety and efficiency in any application involving tubing fittings.

Future Trends in Tubing Fitting Design and Functionality

As the industry evolves, tubing fittings are increasingly driving innovation in design and functionality. Recent trends highlight a shift towards more versatile, durable, and sustainable materials that cater to a variety of applications—from residential plumbing to complex industrial systems. According to a report from the Fluid Power Journal, 65% of manufacturers are integrating smart technology into their fitting designs to enhance performance and efficiency, paving the way for a future where connectivity plays a crucial role in plumbing solutions.

Tips: When selecting tubing fittings for your next project, consider opting for fittings that incorporate advanced materials like PPR-C or reinforced composites, which offer higher resistance to corrosion and temperature fluctuations. Additionally, focus on modular designs that allow for easier maintenance and future upgrades, reducing overall costs in the long run.

Another emerging trend in the field is the increased emphasis on eco-friendly solutions. The market is witnessing a rise in demand for fittings designed with sustainability in mind; the 2023 Global Market Insights report indicates that environmentally-friendly fittings could account for over 40% of the market share by 2025. By embracing these innovations, you not only align with industry standards but also contribute to a more sustainable future in construction and manufacturing practices.

Related Posts

-

Understanding the Types of Tubing Fittings for Optimal Performance

-

7 Essential Insights about Steel Fittings for Optimal Performance

-

Exploring Fittings Steel Market Growth at the 138th Canton Fair in 2025 with Key Industry Insights

-

Exploring Innovative Applications of Tubing Fittings for Modern Plumbing Solutions

-

Top 5 Essential Steel Fittings: Maximizing Durability and Performance in Industrial Applications

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs