Essential Tips for Choosing Valve Fittings for Your Project

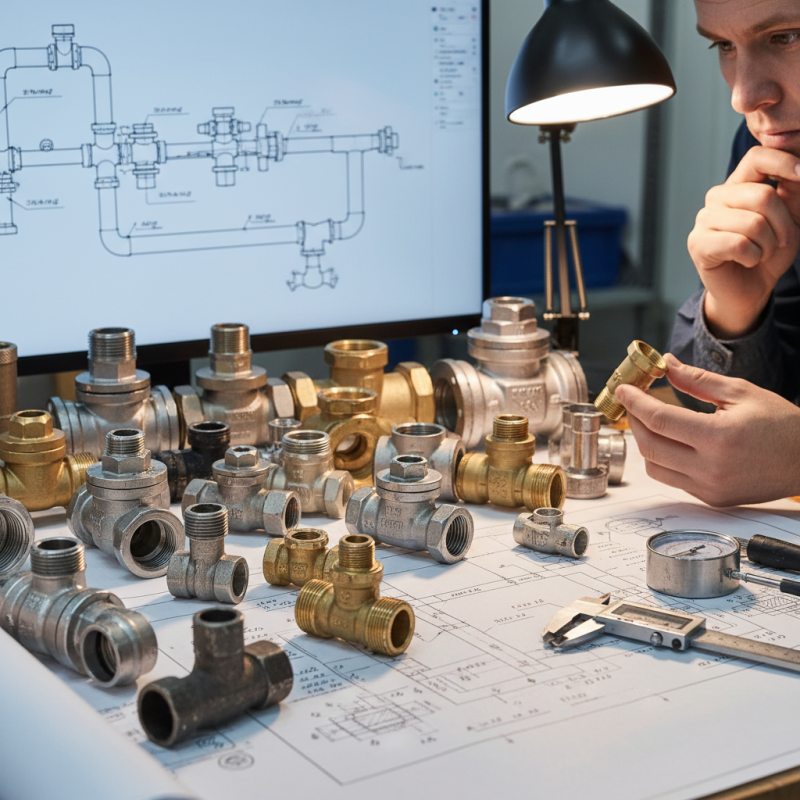

Choosing the right valve fittings is crucial for any project involving fluid control. These fittings come in various types and sizes, making the selection process overwhelming. Understanding the specifications and features of valve fittings will help you avoid unexpected issues later.

Consider the materials used in valve fittings. Different environments may require specific materials for durability. The wrong choice can lead to leaks or failures. You must also think about compatibility with the existing system. Mismatches can be costly.

Don't overlook the importance of proper sizing. Incorrect sizes can disrupt fluid flow. Be aware of pressure ratings as well. High pressure can damage inadequate fittings. Many factors influence your decision, making it essential to reflect carefully on your choices.

Understanding Valve Fittings: Types and Their Applications

When selecting valve fittings for your project, understanding the different types and their applications is crucial. There are various valve types, such as ball valves, gate valves, and check valves. Each type serves a specific function. For instance, ball valves allow for quick shut-off and are ideal for on-off control. Meanwhile, gate valves are better for flow regulation in pipelines.

Tips for choosing the right fitting: consider the medium flowing through the valves. For water systems, standard materials may suffice. But for corrosive substances, opt for resistant materials. Make sure to evaluate the pressure and temperature limits of each fitting. This can prevent failure and ensure safety.

Measure the space available. Compact fittings might fit better in tight locations. Keep in mind that complexity can lead to difficulties in installation and maintenance. Think critically about your requirements. This reflection can save time and resources. Always seek scalable solutions that can adapt to future changes.

Key Factors to Consider When Selecting Valve Fittings

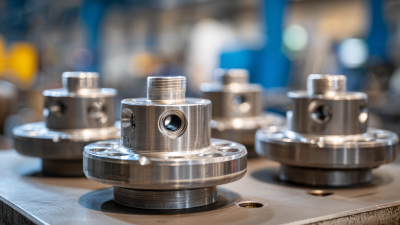

When selecting valve fittings, several key factors are crucial. The material of the fittings plays a significant role. Different environments require specific materials. For instance, stainless steel is ideal for corrosive environments, while PVC may suit less demanding applications. According to a 2022 industry report, corrosion-resistant materials can extend the lifespan of fittings by up to 50%. This prevents costly replacements over time.

Another factor to consider is pressure ratings. Each application will have a specific pressure requirement. Fittings must meet or exceed these ratings to ensure safety and efficiency. Surveys indicate that misuse of fittings, based on pressure miscalculations, leads to failures in over 30% of projects. This statistic highlights the importance of understanding the operational pressures involved.

Lastly, the compatibility of fittings with existing systems cannot be ignored. Mismatched components may lead to leaks and inefficiencies. Ensure that the fittings can connect seamlessly with pipes and other equipment. Regular checks can help identify potential incompatibilities before they become significant issues. Balancing these factors is vital, yet often overlooked, during the selection process.

Industry Standards and Certifications for Valve Fittings

When selecting valve fittings, understanding industry standards and certifications is crucial. These standards ensure compatibility and safety. For instance, the American National Standards Institute (ANSI) provides guidelines for various valve fittings. Compliance with ANSI standards can improve system reliability and performance. A recent report from the Valve Manufacturers Association indicates that up to 30% of valve failures stem from non-compliant fittings.

Additionally, the International Organization for Standardization (ISO) outlines rigorous testing protocols. ISO certifications signal that a product meets stringent quality requirements. In the oil and gas sector, compliance can reduce accidents and downtime significantly. The 2022 Safety Report highlighted that organizations adhering to ISO standards reported 25% fewer incidents than their non-compliant counterparts.

Yet, relying solely on certifications may not suffice. Some manufacturers may cut corners during production. It's essential to verify that the certifications are genuine and up-to-date. Engaging with suppliers and requesting documentation is a necessary step. Doing so can minimize risks and ensure you choose the right fittings for your project.

Essential Tips for Choosing Valve Fittings - Industry Standards and Certifications

Material Selection: How it Affects Performance and Longevity

When selecting valve fittings for projects, material choice is crucial. Different materials impact not just performance but also the longevity of the components. For example, studies show that brass and stainless steel valves can last up to 20 years longer than their plastic counterparts in demanding environments. This considerable difference can affect maintenance costs and project timelines profoundly.

Choosing the right material starts with understanding the application. Corrosive environments require robust materials like stainless steel. In less harsh conditions, materials like PVC may suffice. Pay attention to pressure ratings and temperature thresholds. This knowledge can lead to decisions that save you time and money in the long run.

Tip: Always consult industry standards. They offer guidance on compatibility and durability. Regularly review your choices to adapt to new findings. Materials evolve, and so should your selections. It's essential to balance cost with quality. Sometimes, opting for cheaper options initially leads to higher costs later. Be aware and take time to reflect on your choices. The right valve fitting can make all the difference.

Cost Analysis: Balancing Quality and Budget in Valve Fitting Choices

Choosing the right valve fittings for your project requires a careful balance between quality and budget. It’s tempting to go for the cheaper options, but this might lead to problems down the road. Investing in quality fittings typically means better performance and durability. However, not every high-priced item guarantees satisfaction. Analyze your needs before making a choice.

Consider functionality first. Determine the specific requirements of your project. What will the valve be used for? Under what pressure and temperature? These factors can greatly influence your budget. A cheap fitting may save money initially but could lead to costly repairs or replacements later. Quality fittings can enhance the lifespan of your system.

Tip: Always check the material of the fittings. Some materials are corrosion-resistant and last longer. Compare prices among suppliers but stay focused on performance. It is also useful to assess user reviews. Real experiences can reveal insights that prices alone cannot. Additionally, think about design and compatibility. A fitting that doesn’t align with your current system can create unforeseen expenses. Sometimes, spending a bit more results in significant long-term savings.

Related Posts

-

Understanding Valve Fittings: Key Trends and Innovations Driving Industry Growth in 2023

-

Essential Guide to Choosing the Right Valve Fittings for Optimal Performance

-

How to Choose the Right Fittings and Valves for Your Industrial Needs

-

Top Strategies for Enhancing Performance with Fittings Valves

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs

-

Understanding the Role of Diaphragm Valves in Modern Industrial Applications