10 Essential Tips for Choosing Stainless Steel Sanitary Fittings You Can't Ignore

When it comes to ensuring hygiene and durability in various industries, the choice of materials is critical. Stainless steel sanitary fittings have become a popular choice due to their corrosion resistance, ease of cleaning, and ability to maintain sanitary conditions. However, selecting the right stainless steel sanitary fittings can be a daunting task given the multitude of options available on the market. Understanding the essential aspects to consider is crucial for making an informed decision that will affect not just the functionality, but also the longevity of your systems.

This article will delve into the ten essential tips for choosing stainless steel sanitary fittings that you simply cannot ignore. From understanding the grades of stainless steel to recognizing the importance of proper sizing and pressure ratings, these insights aim to equip you with the knowledge you need to make the right choices. The right fittings not only enhance the efficiency of your operations but also ensure compliance with health standards, making this decision one of the most impactful in any sanitary application. Whether you are working in food processing, pharmaceuticals, or any other sanitation-critical environment, these tips will guide you toward reliable and effective solutions.

Understanding the Importance of Stainless Steel in Sanitary Applications

When it comes to sanitary applications, stainless steel is a material of choice due to its numerous qualities that enhance hygiene and safety. Its inherent resistance to corrosion and rust makes it ideal for environments where cleanliness is paramount. Unlike other materials, stainless steel does not harbor bacteria or pathogens, which is crucial in settings such as food processing, pharmaceuticals, and medical facilities. The non-porous surface of stainless steel prevents the buildup of contaminants, ensuring that sanitation standards are met and maintained.

Another vital aspect of using stainless steel in sanitary fittings is its durability and strength. Stainless steel can withstand high temperatures and pressures, making it suitable for various applications that require rigorous processes. This robustness contributes to a longer lifespan for fittings, reducing the frequency of replacements and minimizing downtime in critical operations. Moreover, stainless steel's aesthetic appeal and ease of cleaning further contribute to its supreme functionality in sanitary settings, ensuring that facilities not only operate efficiently but also maintain a professional appearance.

Key Factors to Consider When Selecting Stainless Steel Sanitary Fittings

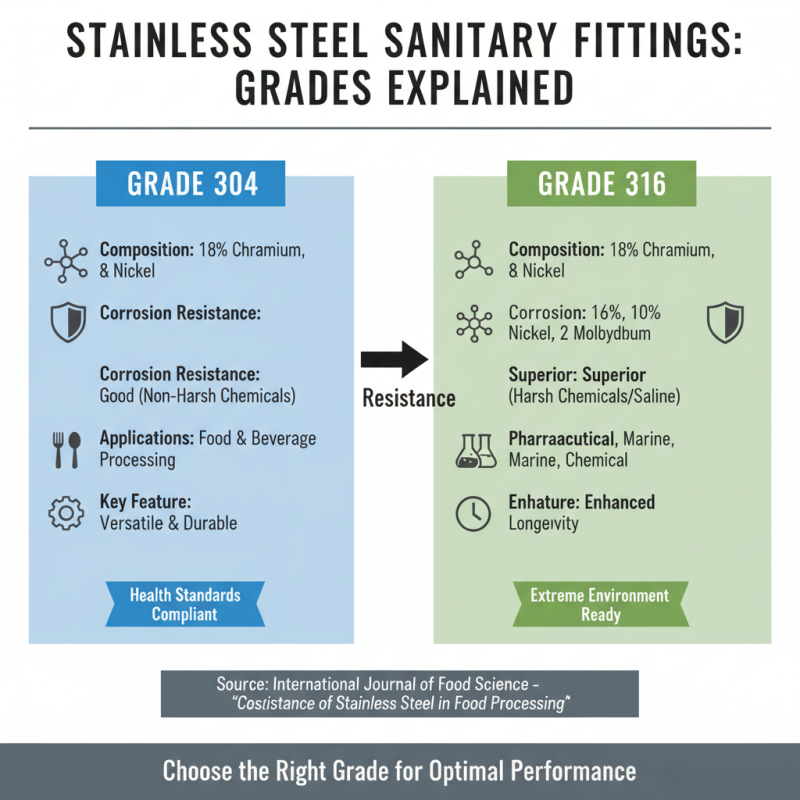

When selecting stainless steel sanitary fittings, several key factors must be taken into account to ensure optimal performance and compliance with industry standards. One of the primary considerations is the grade of stainless steel used in the fittings. Generally, 304 and 316 stainless steel are the most common grades employed in sanitary applications, with 316 showing superior resistance to corrosion, particularly in environments exposed to saltwater or chemical exposure. According to a 2021 report by the International Stainless Steel Forum, corrosion resistance is a significant determinant in the lifecycle cost of fittings, underscoring the importance of selecting the appropriate stainless steel grade for specific applications.

Another crucial factor is the fitting's surface finish, which can impact hygiene and cleaning efficiency. A smooth finish reduces the chance of bacteria adhering to the surface, which is essential for maintaining sanitation in food and pharmaceutical industries. A study published in the Journal of Food Engineering highlights that polished surfaces can reduce microbial attachment by up to 90%, making surface finish an essential consideration when selecting sanitary fittings. Additionally, the fitting’s design and joinery method should be evaluated to ensure compatibility with existing systems and ease of maintenance, ultimately enhancing both safety and efficiency in operational processes.

10 Essential Tips for Choosing Stainless Steel Sanitary Fittings You Can't Ignore

| Tip | Description | Key Factor |

|---|---|---|

| 1. Material Grade | Choose a material grade that suits your specific environment. | Resistance to Corrosion |

| 2. Size and Dimensions | Ensure the fitting matches the size requirements of your system. | Compatibility |

| 3. Surface Finish | Select a smooth surface finish to facilitate cleaning. | Hygiene |

| 4. Certification | Ensure your fittings are certified for your industry standards. | Compliance |

| 5. Temperature Tolerance | Verify the temperature range the fitting can withstand. | Durability |

| 6. Pressure Rating | Choose fittings that can handle the pressure of your system. | Safety |

| 7. Fitting Type | Select the correct type (e.g., elbows, tees) based on your design needs. | Functionality |

| 8. Availability | Check the availability of the fittings for timely procurement. | Supply Chain Efficiency |

| 9. Price | Compare prices to find cost-effective options without compromising quality. | Budget Considerations |

| 10. Supplier Reputation | Research supplier history to ensure reliability and quality. | Trustworthiness |

Common Grades of Stainless Steel and Their Suitability for Sanitary Use

When selecting stainless steel sanitary fittings, understanding the common grades of stainless steel is crucial to ensure appropriate performance and longevity. The most commonly used grades in sanitary applications are 304 and 316 stainless steel. Grade 304 exhibits excellent resistance to corrosion and is suitable for environments not exposed to harsh chemicals. It comprises 18% chromium and 8% nickel, making it versatile for a variety of food and beverage applications. According to the "Corrosion Resistance of Stainless Steel in Food Processing" report by the International Journal of Food Science, 304 stainless steel allows for compliance with health standards while providing durability and performance over time.

On the other hand, 316 stainless steel is preferred for more demanding environments, particularly those that may involve exposure to chlorides or sea environments, where corrosion risk is higher. This grade includes molybdenum, which enhances its resistance to pitting and crevice corrosion. A study published in "Corrosion Science" highlights that 316 stainless steel components can withstand exposure to the aggressive chemicals often found in sanitary processing environments. Thus, while the initial cost might be higher, the long-term benefits in durability and maintenance reduce total lifetime costs significantly. Selecting the appropriate grade based on specific application requirements is essential for optimizing performance and ensuring compliance with sanitary standards.

Essential Certifications and Standards for Sanitary Fittings

When selecting stainless steel sanitary fittings, understanding the essential certifications and standards is crucial for ensuring quality and safety in various applications. Key certifications such as ASTM A270 and ASME BPE are critical benchmarks in the sanitary industry. ASTM A270 specifies the requirements for seamless and welded austenitic stainless steel tubing intended for use in the dairy and food industry, ensuring that materials are safe for food processing and distribution. Meanwhile, ASME BPE sets standards specifically for bioprocessing equipment, focusing on cleanliness, materials, and dimensional requirements.

According to the International Organization for Standardization (ISO), adherence to these standards not only enhances the integrity of sanitary fittings but also minimizes the risk of contamination in sensitive environments. A report by the Stainless Steel Research Institute highlights that fittings and components that meet such rigorous standards have shown an overall 20% reduction in maintenance costs and downtime in industrial applications. Companies that prioritize these certifications are not only ensuring compliance with regulatory bodies but also safeguarding their operations against potential hazards associated with non-compliant materials. In an industry where precision and safety are paramount, the right certifications can significantly influence operational efficiency and product quality.

10 Essential Tips for Choosing Stainless Steel Sanitary Fittings

This chart illustrates the importance of various factors when selecting stainless steel sanitary fittings. Each category is rated on a scale from 1 to 10, based on essential certifications and standards.

Maintenance Tips for Enhancing the Longevity of Stainless Steel Fittings

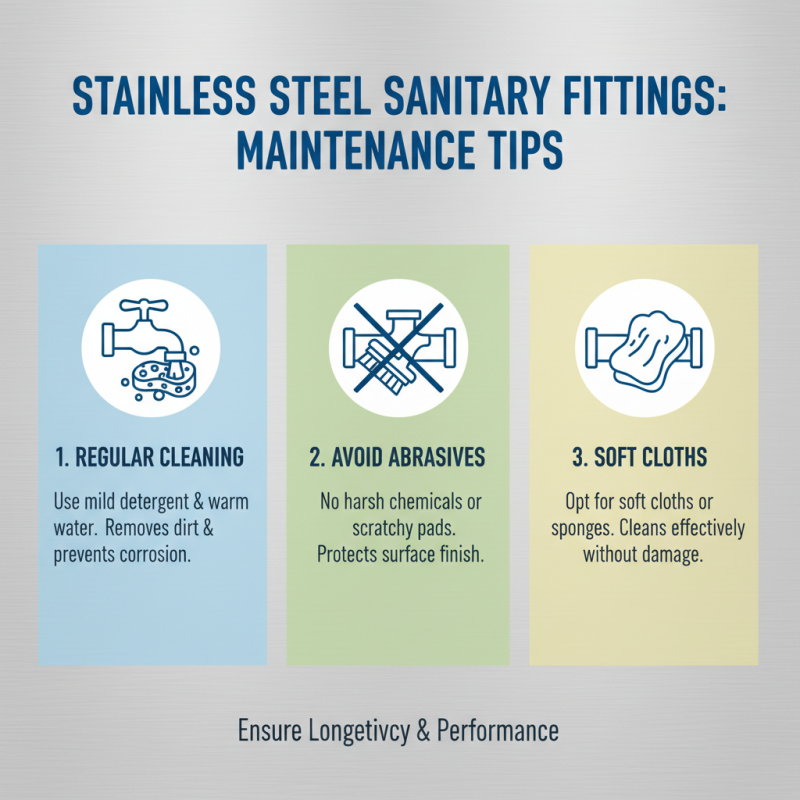

Maintaining stainless steel sanitary fittings is crucial for ensuring their longevity and performance. One of the fundamental maintenance tips is to regularly clean the fittings using a mild detergent and warm water. This simple step not only helps remove dirt and grime but also prevents the buildup of corrosive substances that can compromise the integrity of the fittings over time. Avoid using abrasive materials that could scratch the surface; instead, opt for soft cloths or sponges that effectively clean without damaging the finish.

Another important aspect of maintenance is to frequently inspect the fittings for signs of wear or corrosion. Addressing any issues such as leaks or rust promptly can prevent more significant problems down the line. Additionally, applying a protective coating specifically designed for stainless steel can provide an extra layer of defense against environmental factors. Regular inspections combined with a proactive cleaning regimen will ensure that your stainless steel sanitary fittings remain in optimal condition, fulfilling their role effectively and safely within your system.

Related Posts

-

How to Choose the Right Stainless Sanitary Fittings for Your Project

-

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

-

Why You Need a Comprehensive Sanitary Fittings Catalog for Your Projects

-

Why Sanitary Connectors Are Essential for Maintaining Hygiene in Food Production

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs

-

2025 Top Water Fittings: Essential Guide to Choosing the Best Options