10 Essential Tips for Choosing the Right Sanitary Diaphragm Valve

Choosing the right sanitary diaphragm valve is essential in various industries. These valves are crucial for maintaining hygiene and efficiency in fluid control systems. With numerous options available, how do you make the best choice?

When selecting a sanitary diaphragm valve, consider the material and design. The right valve should resist corrosion and contamination. Look for models that meet sanitary standards. However, balancing cost and quality can be tricky. Many buyers overlook this.

Another key point is the valve's size and compatibility. Ensure it fits within your system without causing pressure issues. Sometimes, a perfect fit doesn’t guarantee performance. Testing the valve in real conditions is often necessary. Don't settle for the first option. Your choice impacts production quality and safety.

Understanding the Different Types of Sanitary Diaphragm Valves

Choosing the right sanitary diaphragm valve requires understanding its various types. Sanitary diaphragm valves primarily fall into three categories: manual, pneumatic, and electric. Each type serves distinct purposes in processing environments. Manual valves offer straightforward operation but may not be suitable for high-precision applications. Reports show that around 40% of facilities use pneumatic valves due to their efficiency in controlling flow rates.

When evaluating these valves, consider material compatibility. The diaphragm material plays a crucial role in performance. For instance, many facilities prefer ethylene propylene diene monomer (EPDM) for its durability against harsh chemicals. Yet, EPDM may lack resistance to certain solvents. This inconsistency can lead to unexpected failures, which 30% of users report experiencing in their operations.

Valves also differ in size and design, affecting installation and maintenance. Compact designs may be favored for space-limited areas, but they sometimes compromise flow capacity. An industry study revealed that improper valve selection can lead to a 20% increase in operational costs. Understanding the functional differences among valve types enables better decision-making. Thus, investing time in research can yield significant returns in efficiency and reliability.

Key Factors to Consider When Selecting a Sanitary Diaphragm Valve

When it comes to selecting a sanitary diaphragm valve, several key factors must be considered. Understanding the operating conditions is essential. The valve's pressure rating and temperature limits should align with your system's needs. For instance, a study by the Sanitary Valve Manufacturer Association noted that 65% of valve failures stem from misalignment with system demands.

Another critical aspect is the material choice. The right material ensures compatibility with the fluids being handled. Stainless steel remains the preferred choice due to its corrosion resistance. Depending on the application, materials like PTFE or rubber may also be relevant. Moreover, improper materials can lead to disruptions, as 40% of plants report contamination issues tied to material failures.

**Tip:** Always verify valve certifications. The certification should include compliance with industry standards. This ensures safety and quality in operations.

Consider the valve's design thoughtfully. A simple design often leads to easier maintenance. Complex designs may present challenges, particularly in cleaning processes. According to industry reports, 30% of maintenance costs are linked to inefficient valve designs.

**Tip:** Assess the ease of disassembly. This aspect is crucial for certification meets and regular checks. Regular maintenance may highlight unseen issues, making this step vital.

Material Selection: Choosing the Right Construction for Your Needs

Material selection is crucial when it comes to sanitary diaphragm valves. Different materials respond differently to various chemicals, temperatures, and pressures. For instance, stainless steel is often favored for its resistance to corrosion and high-temperature resilience. However, it can be expensive and may not always be the best choice for less corrosive applications.

On the other hand, plastics like PVC or PVDF are lightweight and offer good chemical resistance at a lower cost. Yet, they may not withstand high temperatures well. A study by the International Journal of Chemical Engineering noted that about 30% of valve failures are due to improper material selection. This highlights the need for thorough understanding and consideration.

Choosing the right construction also involves understanding the environment where the valve will be used. Some materials may fail under specific conditions, leading to leaks or system failures. Paying attention to factors like pressure ratings and the physical environment is essential. A poorly selected material can lead to significant operational issues and increased maintenance costs, which should prompt a careful evaluation of all options available.

10 Essential Tips for Choosing the Right Sanitary Diaphragm Valve - Material Selection: Choosing the Right Construction for Your Needs

| Material Type | Temperature Range (°C) | Pressure Rating (bar) | Chemical Compatibility | Applications |

|---|---|---|---|---|

| Stainless Steel | -50 to 200 | 10 | Excellent | Food processing, Pharmaceuticals |

| PVC | 0 to 60 | 6 | Moderate | Water treatment, Low-pressure applications |

| PTFE | -200 to 260 | 6 | Excellent | Chemical processing, Sterilization |

| Brass | -20 to 90 | 10 | Good | Water, Air lines |

| Silicone | -50 to 200 | 4 | Good | Food and drink applications |

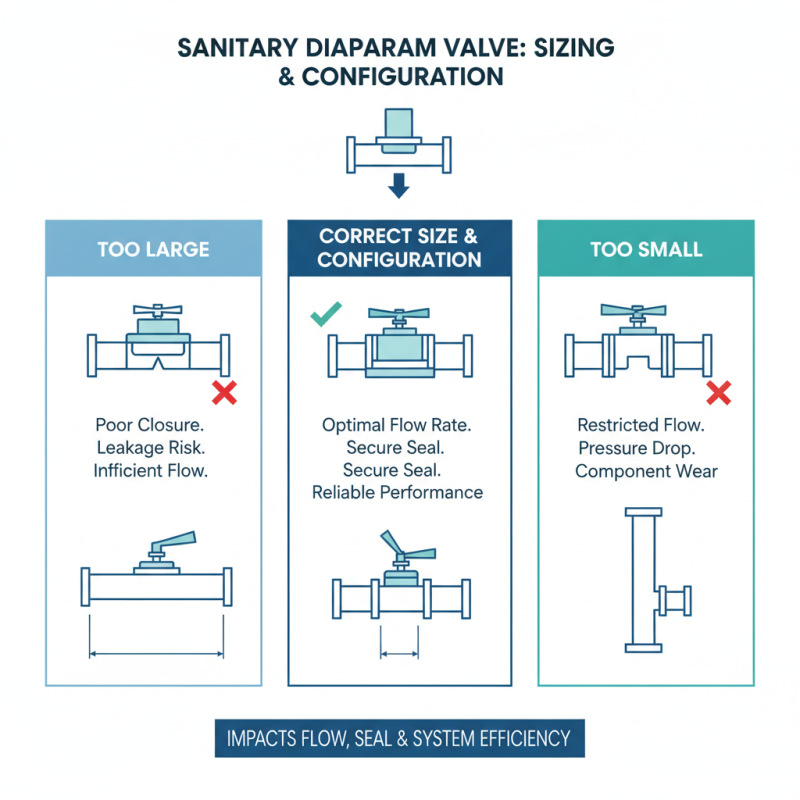

Assessing Valve Sizing and Configuration for Optimal Performance

When selecting a sanitary diaphragm valve, sizing and configuration are crucial. The right size directly impacts flow rates. It can be tempting to choose a valve that's too large or too small. This can lead to poor performance. Oversized valves may not close properly, while undersized ones can restrict flow.

Consider the application and system pressures when sizing. Each process has unique demands. Take precise measurements of pipe diameters. Ensure there is enough space for installation. Proper layout also depends on accessibility for maintenance. A well-placed valve contributes to efficiency.

Don't overlook material compatibility. Different materials react differently within various environments. A mismatch might lead to corrosion or contamination. This could affect the quality of the fluid being processed. Regular reviews of your valve options are needed as systems evolve. Reassessment helps to adapt to any changes in your operational needs. Adjustments in your selection may lead to improved efficiency and safety.

Importance of Certification and Compliance in Sanitary Applications

In sanitary applications, certification and compliance are critical. They ensure that products meet specific safety and quality standards. A valve might look impressive on the outside. However, if it's not certified, it could pose serious risks. Contaminants can easily infiltrate a system during production.

When choosing a sanitary diaphragm valve, ask for the certifications. Look for compliance with industry standards like ASME and ISO. This reflects reliability and safety in your operations. Be wary of valves that lack proper documentation. They can lead to costly clean-ups and quality issues.

Consider the materials used in the valve’s construction. Are they compatible with your application? Sometimes, details are overlooked, leading to potential failures. Regular reviews of compliance are essential. They help identify any lapses before they become major problems. Balancing quality with affordability can be challenging. Always prioritize safety over cost. Failing to do so can have dire consequences.

Related Posts

-

10 Essential Tips for Choosing Stainless Steel Sanitary Fittings You Can't Ignore

-

Why Are Sanitary Connectors Essential for Food Safety?

-

How to Choose Plug Valves for Your Industrial Applications?

-

Top 10 Valve Fittings for Efficient Fluid Control Solutions?

-

Why Are Stainless Steel Fittings Preferred in Construction?

-

Transform Your Bathroom with High-Quality Sanitary Fittings: Insights from 2023 Market Trends