Understanding the Essential Role of Fittings Valves in Modern Fluid Systems

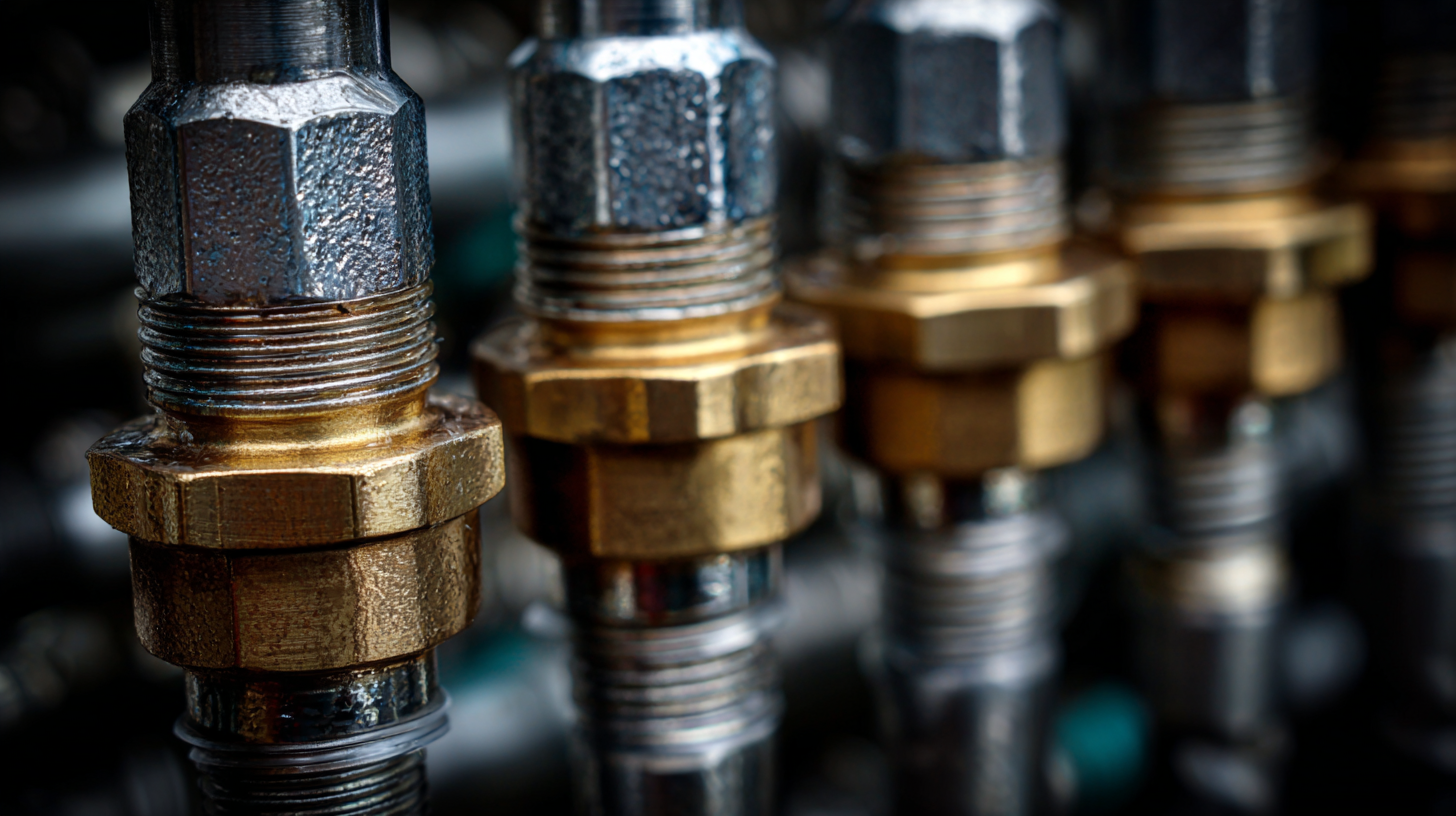

In the complex landscape of modern fluid systems, fittings valves play an indispensable role that often goes unnoticed. These critical components are essential for effectively managing the flow of fluids, ensuring system efficiency and reliability. As industries increasingly depend on intricate piping systems for various applications, understanding the function and importance of fittings valves becomes paramount.

This article aims to provide insights into the various types of fittings valves, their applications, and best practices for their selection and maintenance. By leveraging both digital tools and expert tips, we will explore how these components not only facilitate the seamless transport of fluids but also help mitigate risks associated with fluid management.

Join us as we delve into the vital contributions of fittings valves and how they can enhance the performance of your fluid systems.

The Importance of Fittings Valves in Various Fluid Systems

Fittings valves are crucial components in diverse fluid systems, serving a multitude of functions that enhance efficiency and safety in various applications. In industrial settings, these valves regulate flow and pressure, ensuring that fluids move seamlessly through pipelines. A properly designed fittings valve can prevent leaks and reduce the risk of system failures, which is essential in industries such as oil and gas, pharmaceuticals, and chemical processing. Moreover, they enable precise control of fluid dynamics, ultimately improving operational performance.

In residential plumbing and HVAC systems, fittings valves play a vital role in maintaining comfort and safety. They control water flow in heating systems and manage pressure in water supply lines, significantly impacting daily life. The ability to easily shut off water supply during repairs or emergencies highlights their importance in preventing potential disasters. Thus, fittings valves are indispensable not just in larger industrial frameworks but also in everyday household applications, illustrating their versatility and necessity in both complex and simple fluid systems.

Understanding the Essential Role of Fittings Valves in Modern Fluid Systems

| Fluid System Type | Common Valve Types | Material Used | Operating Pressure (psi) | Temperature Range (°F) | Application Example |

|---|---|---|---|---|---|

| Water Supply | Gate Valve, Globe Valve | Brass, PVC | 50 - 150 | 32 - 140 | Residential Plumbing |

| Oil & Gas | Ball Valve, Check Valve | Stainless Steel, Alloy | 100 - 3000 | -20 - 200 | Crude Oil Transport |

| Chemical Processing | Butterfly Valve, Diaphragm Valve | PTFE, Hastelloy | 50 - 2000 | -40 - 300 | Acid Handling |

| HVAC Systems | Thermostatic Valve, Control Valve | Aluminum, Copper | 30 - 150 | -10 - 160 | Temperature Regulation |

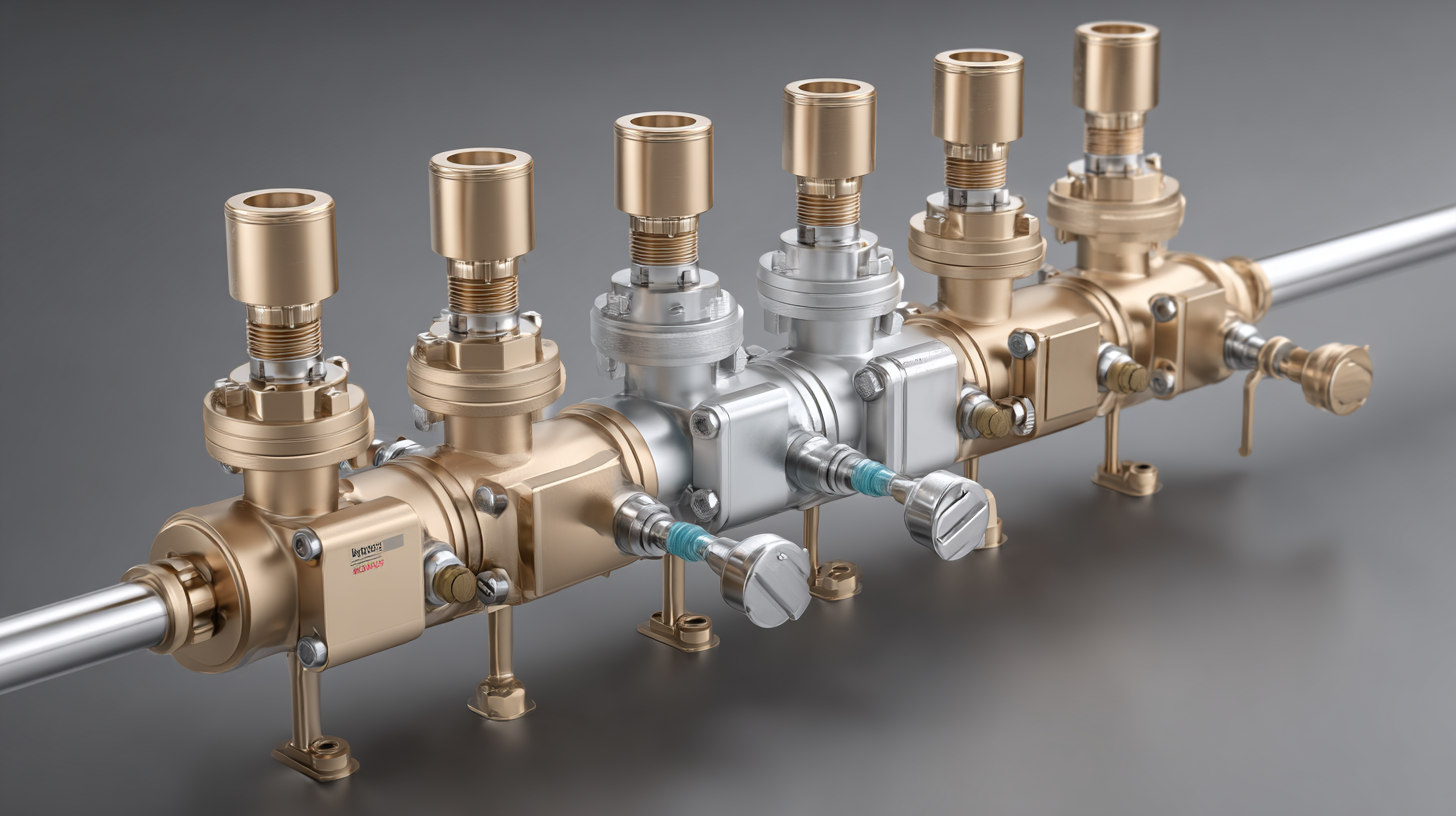

Key Types of Fittings Valves and Their Applications

Fittings valves are crucial components in modern fluid systems, enabling precise control over the flow and direction of fluids. Among the key types of fittings valves, gate valves stand out for their ability to provide a straight flow path with minimal resistance, making them ideal for on/off control in pipelines. Their simple design allows for quick operation, often used in water supply systems and industrial applications where full flow is necessary.

Another important type is the globe valve, known for its versatility in regulating flow. Unlike gate valves, globe valves can throttle the flow, making them suitable for applications requiring fine control, such as in heating systems and chemical processing. Additionally, ball valves offer a reliable option for quick shut-off due to their quarter-turn operation, making them ideal for applications where quick isolation is needed, such as in gas and liquid transport systems. Each type of fittings valve serves its unique purpose, ensuring efficient operation and safety in fluid management applications.

Top 5 Benefits of Using Quality Fittings Valves

In modern fluid systems, the importance of high-quality fittings valves cannot be overstated. One of the primary benefits of using quality fittings valves is enhanced reliability. These components are engineered to withstand various pressures and temperatures, reducing the likelihood of leaks or failures that can disrupt fluid flow and result in costly downtime. When installed, quality fittings valves contribute significantly to the overall stability and longevity of the entire system.

Another critical advantage is improved efficiency. Well-manufactured fittings valves are designed to facilitate better flow control, minimizing pressure losses and energy consumption. By ensuring that fluids move seamlessly through the system, these valves help maintain optimal operational performance. Additionally, quality fittings valves are often easier to maintain, as they are built with materials that resist corrosion and wear, thereby lower maintenance costs over time. Ultimately, the choice of fittings valves plays a pivotal role in the success and sustainability of fluid systems across various industries.

Critical Factors in Selecting the Right Fittings Valves

When selecting fittings valves for modern fluid systems, several critical factors must be considered to ensure optimal performance and longevity. One of the primary considerations is the material composition of the fittings. According to a report by the American Society of Mechanical Engineers (ASME), the right material can significantly reduce the risk of corrosion and contamination, leading to a 20-30% increase in system efficiency. For example, stainless steel is often preferred in environments where chemical resistance is paramount, while PVC is commonly used in less aggressive settings.

Another essential aspect is the pressure and temperature ratings of the fittings valves. The ANSI B16.34 standard outlines the importance of selecting valves that can withstand the specific operating conditions of a system. Fittings that exceed these ratings can lead to catastrophic failures, resulting in downtime and costly repairs. A study from the Fluid Power Journal indicates that improper selection of fittings can account for nearly 25% of system failures in hydraulic applications, underscoring the significance of thorough analysis during the procurement process. By evaluating these factors meticulously, engineers can ensure reliable and efficient fluid management in their systems.

Maintenance Tips for Enhanced Performance of Fittings Valves

Fittings valves play a critical role in the efficiency and safety of modern fluid systems. Regular maintenance is essential to enhance their performance and longevity. One effective strategy is to ensure that valves are inspected routinely for wear and tear, which can prevent potential leaks and operational failures. Cleaning the valve components can also help maintain their functionality, particularly in systems dealing with corrosive or particulate-laden fluids.

In addition to routine inspections, leveraging advanced monitoring technologies can significantly contribute to the effective maintenance of fittings valves. These systems allow for real-time assessment of valve performance, facilitating timely interventions that can mitigate risks and improve reliability. For instance, incorporating pressure relief valve advancements can lead to reduced emissions while boosting overall system efficiency. Moreover, keeping abreast of industrial standards ensures that the fittings and valves comply with safety and performance benchmarks, which is vital for optimizing operational outputs and maintaining sustainable practices in fluid management.

Related Posts

-

Exploring Sanitary Connectors Market Trends at the 138th Canton Fair 2025

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs

-

How to Choose the Right Ball Valve for Your Application

-

Exploring Fittings Steel Market Growth at the 138th Canton Fair in 2025 with Key Industry Insights

-

6 Tips to Choose the Right Sanitary Connectors for Optimal Hygiene Compliance

-

7 Best Weld Fittings to Enhance Your Industrial Projects