Essential Brewery Fittings Every Craft Brewer Must Have for Optimal Production

In the ever-growing craft brewing industry, the significance of high-quality brewery fittings cannot be overstated. According to the Brewers Association, the craft beer segment has seen a remarkable 20% growth in production volume over the past three years, underscoring the need for brewers to optimize their operations for efficiency and quality. Essential brewery fittings, such as fermenters, kegs, and filtering systems, are critical components that directly impact the brewing process and the final product quality. A report from Mordor Intelligence indicates that the global brewery fittings market is projected to reach $1.9 billion by 2026, driven by increasing consumer demand for artisanal beers and the expansion of microbreweries. Therefore, understanding which fittings are vital is essential for craft brewers aiming to scale production effectively while maintaining the distinctive quality of their brews.

Essential Mash Tuns: Key Features and Benefits for Craft Brewing Success

When it comes to craft brewing, the mash tun is an essential piece of equipment that can greatly influence the efficiency and quality of the brewing process. According to the Brewer's Association, nearly 78% of craft brewers identify fermentation as the most critical stage in brewing, but the foundation of that process begins with effective mashing. A high-quality mash tun allows brewers to finely control the temperature and timing of the mash, which can optimize enzyme activity that converts starches into fermentable sugars.

Modern mash tuns are designed with advanced features that enhance performance. For instance, many units now come equipped with built-in temperature control systems and advanced insulation to maintain consistent temperatures throughout the mashing process, which can improve overall brew quality. A report by Market Research Future suggests that the craft beer market is projected to grow by 4.4% annually, underscoring the importance of investing in reliable brewing equipment like mash tuns to meet increasing consumer demand. Furthermore, a well-designed mash tun can facilitate easier cleaning and maintenance, contributing to operational efficiency and hygiene—critical factors for any successful brewing operation.

Essential Brewery Fittings for Optimal Production

The Ultimate Guide to Choosing Fermentation Tanks for Optimal Yeast Health

When considering optimal yeast health in fermentation tanks, it's essential for craft brewers to choose equipment that maintains precise temperature control and an anaerobic environment. Research shows that temperature fluctuations can significantly impact yeast performance, reducing fermentation efficiency by up to 20%. Utilizing double-walled fermentation tanks with glycol jacket systems can help regulate temperature effectively, thus promoting a healthier yeast population and improving beer quality.

Moreover, the tank material plays a crucial role in yeast health. Stainless steel, which is non-reactive and easy to clean, reduces the risk of contamination. A study indicates that cleanliness in fermentation environments can enhance yeast activity by 30%, as it minimizes off-flavors and encourages a dominant yeast culture. Additionally, incorporating conical fermentation tanks can optimize yeast harvesting and repitching processes, which are vital for ensuring consistency in flavor profiles. Robust fittings and fittings that allow for thorough cleaning and maintenance are not just optional; they are critical for any craft brewery aiming for excellence in fermentation and brewing efficiency.

Must-Have Kegs: Comparing Different Materials and Sizes for Craft Breweries

When it comes to setting up a craft brewery, selecting the right kegs is crucial for both

storage and marketing. Various materials such as

stainless steel, aluminum, and plastic each offer unique benefits.

Stainless steel kegs, for instance, are renowned for their durebility and resistance to corrosion, making them ideal for long-term use.

On the other hand, aluminum kegs are lighter and often more cost-effective, which can be advantageous for smaller breweries focusing on

mobility and transport.

Size also plays a significant role in keg selection.

Smaller craft breweries may prefer micro-kegs for limited releases and events, while larger ones may opt for half-barrel kegs to meet

higher demand. Recent innovations, such as keg collars with integrated tap handle labels, are making it easier for breweries to manage

branding and logistics. This type of solution not only streamlines operations but also enhances the customer experience by ensuring clear

labeling and presentation. As the craft beer market continues to evolve, effective keg solutions will remain a fundamental aspect of optimized production.

Wort Chillers: Best Practices for Efficient Cooling to Improve Quality

Efficient cooling is a critical step in the brewing process, significantly impacting beer quality and yield. Wort chillers play an essential role by reducing the temperature of wort quickly after boiling, which not only helps to achieve optimal fermentation temperatures but also minimizes the risk of contamination. According to a survey by the Brewers Association, brewers using efficient cooling techniques reported a 20% increase in production output on average, showcasing the direct correlation between cooling efficiency and overall brewing success.

To maximize the performance of wort chillers, best practices should be implemented. For instance, utilizing a counterflow chiller can improve cooling efficiency by allowing the wort and cooling water to flow in opposite directions, resulting in faster heat exchange. Industry data indicates that brewers who adopted this method experienced a reduction in cooling time by up to 30%, significantly speeding up batch turnover. Furthermore, maintaining appropriate water temperatures and flow rates ensures that the chilling process remains effective. Investing in quality insulation and regular maintenance can also prevent heat loss and optimize the cooling process, further enhancing beer quality and consistency.

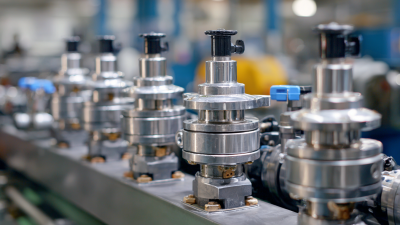

Essential Tubing and Fittings: Ensuring Safety and Hygiene in Craft Brewing Processes

In craft brewing, ensuring safety and hygiene during the brewing process is paramount. Essential tubing and fittings play a critical role in maintaining the quality of the beer while preventing contamination. The use of food-grade silicone and stainless steel tubing is highly recommended, as these materials are resistant to bacterial growth and easy to clean. Breweries should invest in high-quality fittings that provide secure connections to minimize the risk of leaks or failures during production.

Moreover, regular inspection and maintenance of tubing and fittings are vital to guarantee optimal performance and safety. Breweries must implement a routine cleaning schedule, utilizing sanitizing solutions that are safe for brewing equipment. This practice not only preserves the integrity of the brewing process but also enhances the overall flavor profile of the beer. By prioritizing the right materials and maintenance protocols, craft brewers can ensure a hygienic environment that fosters quality production.

Related Posts

-

The Ultimate Guide to Understanding and Choosing Butterfly Valves for Your Industrial Needs

-

Ultimate Sanitary Connectors Checklist for Ensuring Compliance and Efficiency

-

How to Choose the Right Sanitary Pipe Fittings for Your Plumbing Needs

-

Top Strategies for Enhancing Performance with Fittings Valves

-

How to Select the Right Pump Valves for Your Industrial Applications

-

Understanding the Types of Tubing Fittings for Optimal Performance