How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

Selecting the appropriate stainless steel fittings is crucial for ensuring efficient performance and longevity in various applications across multiple industries. According to a recent market analysis report by Grand View Research, the global stainless steel fittings market is projected to reach $8.7 billion by 2028, indicating a significant demand driven by the construction and oil and gas sectors.

Selecting the appropriate stainless steel fittings is crucial for ensuring efficient performance and longevity in various applications across multiple industries. According to a recent market analysis report by Grand View Research, the global stainless steel fittings market is projected to reach $8.7 billion by 2028, indicating a significant demand driven by the construction and oil and gas sectors.

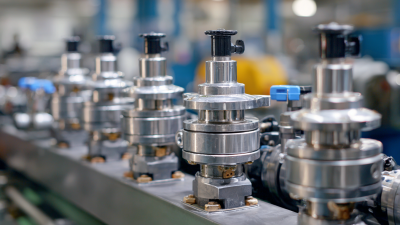

With the wide variety of stainless steel fittings available—ranging from flanges to valves—understanding the key factors that influence their performance is essential for industry professionals. Factors such as corrosion resistance, temperature tolerance, and specific application requirements must be carefully evaluated. Furthermore, adhering to industry standards like ASTM and ASME can enhance reliability and safety in installations.

This article delves into critical considerations and insights for choosing the right stainless steel fittings to optimize performance and ensure sustainability in your projects.

Understanding Stainless Steel Grades and Their Applications

When selecting the right stainless steel fittings, understanding the different grades and their applications is crucial. Stainless steel grades, such as SS 304L, SS 316, and SS 316L, are certified to meet specific quality standards, reflecting their suitability for various environments. For example, grade SS 316 is known for its superior corrosion resistance and is often used in marine applications, making it an optimal choice for fittings exposed to harsh conditions.

When selecting the right stainless steel fittings, understanding the different grades and their applications is crucial. Stainless steel grades, such as SS 304L, SS 316, and SS 316L, are certified to meet specific quality standards, reflecting their suitability for various environments. For example, grade SS 316 is known for its superior corrosion resistance and is often used in marine applications, making it an optimal choice for fittings exposed to harsh conditions.

The mechanical properties and performance of these stainless steel grades are not only influenced by their composition but also by their processing techniques. Research into static recrystallization characteristics and advanced manufacturing methods has shown that optimized compositions can significantly enhance the functionality of stainless steel, especially in demanding applications like cryogenic storage or structural components in nuclear setups. Understanding these factors can aid in making informed decisions that lead to optimal performance and durability in engineered products.

Identifying Essential Performance Factors for Stainless Steel Fittings

When selecting stainless steel fittings, understanding essential performance factors is crucial for ensuring optimal functionality and durability. First and foremost, the grade of stainless steel plays a significant role. Common grades like 304 and 316 exhibit different levels of corrosion resistance and strength. For instance, while 304 is widely used in standard environments, 316 contains molybdenum, which enhances its resistance against chloride corrosion, making it more suitable for marine or chemical applications.

Another critical factor is the fitting's design and compatibility with existing piping systems. Properly designed fittings ensure smooth flow and reduce turbulence, which can lead to wear and energy inefficiencies. It's essential to consider the fitting’s pressure rating and temperature thresholds as well; mismatched specifications may lead to leaks or failures in high-stress situations. Lastly, certifications from recognized standards organizations can provide assurance of quality, further reinforcing the performance reliability of the chosen fittings. By considering these factors, professionals can make informed decisions that enhance the overall integrity of their plumbing or industrial systems.

Key Performance Factors for Stainless Steel Fittings

Evaluating Compatibility with Fluid Types and Environmental Conditions

When selecting stainless steel fittings, a crucial step is evaluating their compatibility with the specific fluid types they will interact with. Different fluids can have varying effects on stainless steel, depending on their chemical composition and properties. For example, corrosive substances like acids and bases can lead to preferential corrosion in certain grades of stainless steel. Thus, understanding the chemical compatibility is vital to prevent premature failure of the fittings and ensure a reliable system.

In addition to fluid types, environmental conditions play a significant role in the performance of stainless steel fittings. Factors such as temperature, pressure, and exposure to humidity or seawater can affect the integrity of the fittings. For instance, while many stainless steel grades perform well in dry conditions, they might succumbing to pitting or crevice corrosion in more aggressive environments. Therefore, it is essential to assess the operational environment and select fittings that can withstand the specific conditions of the application, ensuring long-term durability and functionality.

Analyzing Cost vs. Quality: Making Informed Purchasing Decisions

When selecting stainless steel fittings, the balance between cost and quality is crucial for making informed purchasing decisions. High-quality fittings may come at a premium, but they often offer longer service life, enhanced resistance to corrosion, and superior performance under pressure. This makes them a worthwhile investment, especially in applications where reliability is paramount, such as in chemical processing or marine environments. Conversely, opting for lower-cost options can lead to increased maintenance costs and frequent replacements, ultimately undermining cost savings.

Industry insights suggest that manufacturers and suppliers should be evaluated not just on price but on the overall value they provide. This includes assessing the material certifications, production methods, and warranty offerings. Investing in fittings from reputable manufacturers can ensure compliance with industry standards, which can be a crucial factor in preventing costly downtimes or safety failures. Therefore, when navigating the cost versus quality debate, it is essential to prioritize long-term benefits over initial expenditures to achieve optimal performance in various applications.

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

| Fitting Type | Material Grade | Size (inches) | Estimated Cost (USD) | Recommended Usage |

|---|---|---|---|---|

| Elbow | 304 | 1" | 5.00 | Piping |

| Tee | 316 | 3/4" | 6.50 | Fluid transfer |

| Coupling | 304 | 1/2" | 3.75 | General purpose |

| Reducer | 316 | 2" to 1" | 10.00 | Pressure systems |

| Cap | 304 | 1" | 4.25 | End of pipeline |

Best Practices for Maintenance and Longevity of Stainless Steel Fittings

When it comes to maintaining stainless steel fittings, implementing best practices can significantly enhance their lifespan and performance. Regular inspections play a crucial role in identifying any signs of wear or corrosion. By promptly addressing minor issues, you can prevent more extensive damage down the line. Keeping the fittings clean and free from contaminants is equally essential, as dirt and debris can exacerbate corrosion and hinder functionality.

Tips: Always use a soft cloth or sponge with a mild detergent to clean stainless steel fittings. Avoid abrasive cleaners that may scratch the surface, leading to potential rust over time. Additionally, it’s beneficial to apply a protective coating or sealant periodically, which can help guard against environmental factors.

Another essential factor in maintaining stainless steel fittings is ensuring proper installation and alignment. Misalignment can cause undue stress on the fittings, resulting in leaks or failure. Regularly check the torque settings and re-tighten connections as necessary to maintain optimal performance.

Tips: When reinstalling fittings, ensure the gaskets or seals are in good condition and replace them if there are any signs of damage. Proper torque specifications provided by the manufacturer should always be followed to prevent over-tightening, which can compromise the integrity of the fittings.

Related Posts

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

7 Best Weld Fittings to Enhance Your Industrial Projects

-

How to Choose the Right Sanitary Pipe Fittings for Your Plumbing Needs

-

How to Select the Right Pump Valves for Your Industrial Applications

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

7 Essential Features to Look for in Sanitary Fittings