The Complete Guide to Choosing the Right Stainless Steel Fittings for Your Plumbing Projects

When it comes to plumbing projects, selecting the right materials is crucial for ensuring long-lasting and effective performance. Among these materials, stainless steel fittings stand out for their durability, resistance to corrosion, and versatility in a variety of applications. In this comprehensive guide, we will explore the essential factors to consider when choosing stainless steel fittings for your plumbing systems. From understanding the different types available to evaluating their specific features, this guide aims to equip you with the knowledge necessary to make informed decisions.

Whether you're a professional plumber or a DIY enthusiast, knowing how to select the right stainless steel fittings can significantly enhance the quality of your work. With a variety of options on the market, it can be overwhelming to determine which fittings best suit your project's needs. This guide breaks down the critical aspects of stainless steel fittings, including size, shape, and compatibility with other materials, to help you navigate the selection process with confidence.

As we dive deeper into the world of stainless steel fittings, we will also address common questions and misconceptions, ensuring that you are well-prepared to tackle your plumbing projects effectively. By the end of this guide, you'll have a clear understanding of how to choose the right stainless steel fittings, allowing you to optimize your plumbing solutions for both performance and longevity.

Understanding Stainless Steel Grades: Which One to Choose for Your Plumbing Needs

When selecting stainless steel fittings for plumbing projects, understanding the various grades of stainless steel is crucial.

The two most common grades are austenitic and ferritic. Austenitic stainless steels, such as grade 304, are known for their high corrosion resistance and excellent weldability, making them suitable for a wide range of plumbing applications. According to industry reports, austenitic steel accounts for a significant portion of the global stainless steel seamless pipes market, driven by its use in the oil and gas sector and other demanding environments.

On the other hand, ferritic stainless steels, like grade 430, offer good corrosion resistance and are generally more affordable, but they lack some of the structural integrity found in austenitic grades. Duplex stainless steels, which combine properties of both austenitic and ferritic steels, provide higher strength and enhanced resistance to stress corrosion cracking, making them an excellent choice for challenging applications.

A recent market evaluation highlighted that companies focusing on advanced metallurgy and innovation are thriving, with leaders in this sector investing heavily in developing sustainable solutions to meet industry needs.

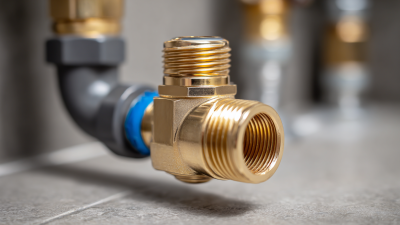

Key Properties of Stainless Steel Fittings: Corrosion Resistance and Strength Explained

When it comes to plumbing projects, choosing the right stainless steel fittings is crucial due to their key properties: corrosion resistance and strength. Stainless steel is an alloy typically composed of iron, carbon, and a minimum of 10.5% chromium. This chromium content is what provides stainless steel its remarkable ability to resist rust and corrosion, making it the perfect choice for both indoor and outdoor plumbing applications. Whether exposed to moisture, chemicals, or varying temperatures, stainless steel fittings maintain their integrity, significantly enhancing the longevity of plumbing systems.

In addition to corrosion resistance, the strength of stainless steel fittings cannot be overlooked. They possess a high tensile strength, which means they can withstand substantial pressure and stress without deforming. This is particularly important in plumbing, where fittings often face fluctuating pressure levels. The durability of stainless steel ensures that these fittings can handle the rigors of daily use while minimizing the risk of leaks or failures. By understanding these properties, plumbers and DIY enthusiasts alike can make informed decisions that ensure the success and safety of their plumbing projects.

Cost Analysis: Comparing Stainless Steel Fittings with Other Plumbing Materials

When considering stainless steel fittings for plumbing projects, it’s crucial to conduct a thorough cost analysis compared to other plumbing materials. The piping and fittings market in North America is expected to grow by USD 14.84 billion from 2022 to 2027, showcasing a robust increase fueled by heightened exploration and production activities. This growth signals a rising demand for durable and high-quality materials, such as stainless steel, which is known for its corrosion resistance and longevity.

Moreover, as remodeling and renovating activities continue to rise, stainless steel fittings become increasingly attractive for both homeowners and contractors looking for reliable and cost-effective solutions. The North America Plumbing Parts Market Research Report anticipates that the ongoing government investments in infrastructure will further drive market growth, emphasizing the importance of choosing the right materials that can withstand time and usage. Such insights suggest that stainless steel fittings not only represent a wise investment in terms of initial costs but also assure long-term savings through their lower maintenance and replacement needs.

Installation Techniques: Best Practices for Maximizing the Longevity of Stainless Steel Fittings

When installing stainless steel fittings in your plumbing projects, employing the right techniques can significantly enhance their durability and performance. Begin by ensuring that all surfaces are clean and free from debris before assembly. This will provide a proper seal and reduce the risk of leaks. Additionally, using appropriate thread sealants can help prevent corrosion and maintain the integrity of the fittings over time.

Tips: Always refer to the manufacturer’s specifications for torque requirements when tightening your fittings. Over-tightening can lead to cracks or damage, while under-tightening may result in leaks. It’s also advisable to inspect the fittings regularly, especially in high-pressure or high-temperature environments, to catch any signs of wear early.

Furthermore, consider utilizing a proper alignment tool during installation. Misalignment can lead to stress on the fittings, potentially causing failure. Using a pipe wrench with care is also crucial; wrapping it with cloth can prevent scratches and marks that could compromise the finish. Following these best practices will not only maximize the longevity of your stainless steel fittings but also ensure a reliable and functional plumbing system.

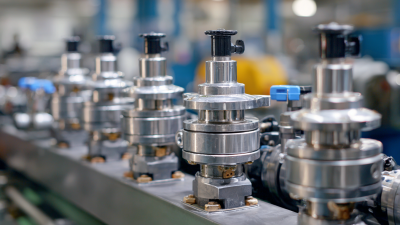

Industry Standards: Compliance and Certification Requirements for Stainless Steel in Plumbing

When selecting stainless steel fittings for plumbing projects, it's essential to consider industry standards and compliance requirements. Stainless steel used in plumbing applications must meet specific certification criteria to ensure durability and safety. Key standards are set by organizations such as ASTM International and the International Organization for Standardization (ISO), which define the material properties, manufacturing processes, and testing methods necessary for reliable performance in plumbing systems.

Compliance with these standards not only helps in selecting high-quality fittings but also ensures that the plumbing systems adhere to local and international regulations. This is particularly important for applications that require sanitary conditions, such as drinking water systems. Properly certified stainless steel fittings resist corrosion, provide longevity, and minimize maintenance costs, making them a worthy investment that aligns with industry best practices. As the demand for resilient and compliant materials grows, businesses in the plumbing sector must stay informed about these standards to remain competitive and meet the needs of their customers effectively.

The Complete Guide to Choosing the Right Stainless Steel Fittings for Your Plumbing Projects

This chart presents the corrosion resistance of various types of stainless steel fittings commonly used in plumbing projects. Type 316 exhibits the highest corrosion resistance, making it ideal for harsh environments, while Type 430 offers the lowest resistance among the options shown.

Related Posts

-

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

-

The Ultimate Guide to Choosing the Best Sanitary Tubing for Your Business Needs

-

The Ultimate Guide to Choosing the Right Sanitary Fittings for Your Facility

-

Exploring Innovative Applications of Tubing Fittings for Modern Plumbing Solutions

-

How to Select the Right Pump Valves for Your Industrial Applications

-

How to Choose the Right Diaphragm Valves for Your Industrial Applications