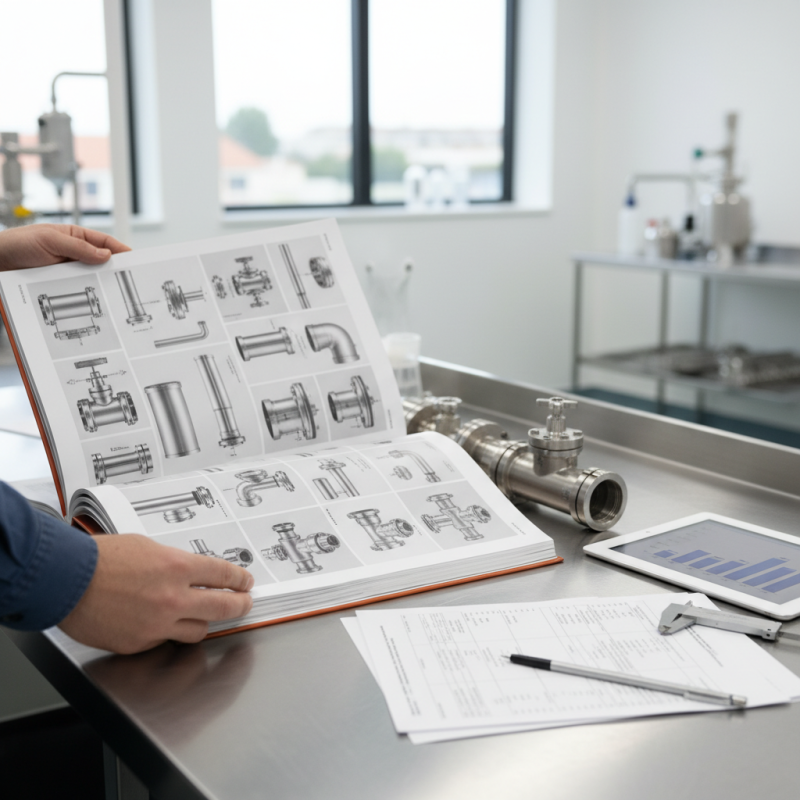

How to Choose the Right Sanitary Fittings Catalog for Your Needs?

Choosing the right sanitary fittings catalog is essential for any project. According to a recent report by Industry Research, the global sanitary fittings market is projected to reach $2.5 billion by 2025. This growth highlights the increasing demand for quality sanitary solutions across various sectors.

Selecting the proper sanitary fittings is often complex. Many buyers overlook specific requirements, such as material compatibility and intended application. This can lead to costly mistakes or installation issues. Data indicates that improper installation or selection can increase maintenance costs by up to 40%.

Understanding your needs is crucial. Assessing the environment, types of fluids handled, and regulatory requirements helps narrow your options. A detailed sanitary fittings catalog can provide invaluable insights, but navigating it demands careful consideration. Proper choices not only enhance efficiency but also ensure compliance and safety.

Understanding Your Sanitary Fitting Requirements

Understanding your sanitary fitting requirements involves evaluating your specific needs. Start by assessing the type of installation. Are you working on a commercial building or a residential project? Each has different standards and demands. For example, a restaurant might need fittings that can withstand high temperatures and frequent usage. In contrast, a home might prioritize aesthetics alongside function.

Next, consider the materials. Stainless steel, for example, is durable and resistant to corrosion. But it may not always match the decor of a home. Plastic fittings can be cost-effective and easy to install, yet they might lack the longevity needed for some applications. Look at the long-term implications of your choice. This step often gets overlooked but is crucial.

Finally, think about the size and dimensions of the fittings. Measure the space accurately to ensure a perfect fit. Oversized fittings can complicate installations, while undersized ones may not function properly. Reflections on past projects can guide you. Remember, it's about finding that balance between practicality and form. Every choice counts.

How to Choose the Right Sanitary Fittings Catalog for Your Needs? - Understanding Your Sanitary Fitting Requirements

| Fitting Type | Material | Size Range (mm) | Pressure Rating (bar) | Application |

|---|---|---|---|---|

| Elbow | Stainless Steel | 15 - 100 | 20 | Water Supply |

| Tee | Brass | 10 - 80 | 16 | Gas Distribution |

| Valve | Plastic | 20 - 50 | 10 | Chemical Processing |

| Coupling | Copper | 15 - 90 | 25 | Water and Sewer |

| Reducer | Stainless Steel | 20 - 75 | 18 | HVAC Systems |

Types of Sanitary Fittings Available in the Market

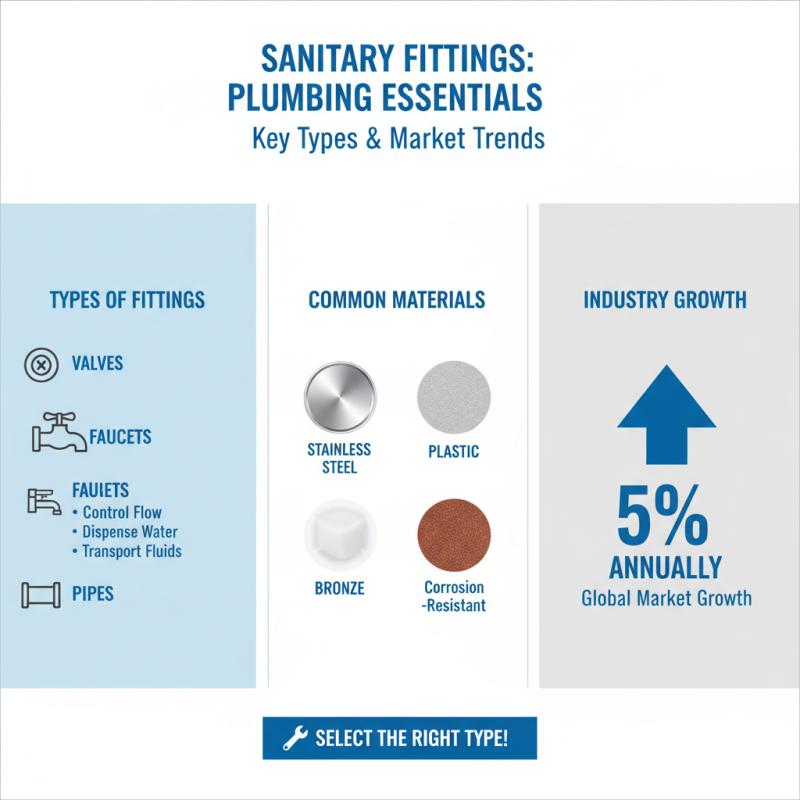

Sanitary fittings play a crucial role in plumbing systems. The types of sanitary fittings available in the market vary widely. Common categories include valves, faucets, and pipes. Each type serves a specific function and comes in different materials like stainless steel, plastic, and bronze. According to a recent industry report, the global market for sanitary fittings is expected to grow by 5% annually, highlighting the importance of selecting the right type.

Valves are essential for controlling the flow of fluids. They can be ball valves or gate valves, each having distinct advantages. Ball valves often offer better sealing. On the other hand, gate valves provide smooth fluid transition. Choosing the wrong type may lead to leaks or inefficiencies. This emphasizes the need for understanding your unique requirements.

Faucets are another critical aspect. They come in various styles, including pull-down and wall-mounted. Each design serves different spaces and functions. A mismatch in faucet choice can impact usability and aesthetics. Many buyers overlook this detail and later regret their decision. It's vital to assess your needs carefully.

Evaluating Quality and Safety Standards in Sanitary Fittings

When selecting sanitary fittings, quality and safety standards are crucial. Evaluating materials, certifications, and production processes can help ensure safety. Look for products made from durable materials like stainless steel or high-quality plastics. These materials resist corrosion and are easier to clean. Check if the fittings comply with relevant safety standards.

Tips: Always ask for certification documents. These can verify the product’s compliance with regulatory guidelines. Don’t overlook the importance of user feedback. Reviews can provide insights into the performance and durability of the fittings.

Understanding the manufacturing process can also shed light on quality. Ethical production practices often lead to better, safer products. Look for suppliers who prioritize quality assurance. Sometimes, cheaper options may save money but compromise safety. Always think long-term about the value of investing in high-quality fittings.

Comparing Costs and Value in Sanitary Fitting Catalogs

When selecting sanitary fittings, understanding costs and value is crucial. A recent industry report indicates that prices can vary significantly among catalogs. Costs may fluctuate from $500 to $2,000 depending on quality and specifications. Often, lower prices come with compromises in durability or compliance with standards.

Value goes beyond just price. Consider the longevity of materials used. For instance, fittings made from stainless steel generally last longer than those made from plastic. Depending on your project scale, this choice can lead to savings over time. Many contractors fail to notice the hidden costs of maintenance and replacements.

Additionally, not all catalogs provide comparable product descriptions. Some may lack essential details on certifications or warranties. This can affect the overall project budget. It's easy to get lost in low initial costs, but reflecting on potential long-term benefits is vital. Aim for a balance between quality and cost.

Tips for Selecting the Right Supplier for Sanitary Fittings

Selecting the right supplier for sanitary fittings is crucial for successful projects. Start by researching potential suppliers. Look for those with strong industry experience. Check their reputation in the market. Online reviews can provide insights into reliability. Word-of-mouth recommendations from colleagues are also valuable.

Evaluate the product range offered by each supplier. A diverse catalog can meet various needs. Make sure they provide quality materials. You want fittings that are durable and compliant with standards. Quality often correlates with the supplier's reliability. Don’t hesitate to request samples. Testing products helps avoid future issues.

Communication is key. Contact potential suppliers and assess their responsiveness. Are they open to answering questions? Are they willing to provide technical support? A supplier's willingness to assist can indicate their commitment to customer care. Reflect on your experiences. Did the supplier communicate effectively? Poor communication can lead to misunderstandings. Choosing wisely from the start saves time and resources later.

Sanitary Fittings Selection Criteria

Related Posts

-

Transform Your Bathroom with High-Quality Sanitary Fittings: Insights from 2023 Market Trends

-

7 Essential Features to Look for in Sanitary Fittings

-

How to Choose the Right Diaphragm Valves for Your Industrial Applications

-

The Ultimate Guide to Choosing the Best Sanitary Tubing for Your Business Needs

-

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing

-

7 Compelling Reasons to Choose the Right Brewery Fittings for Your Craft Business