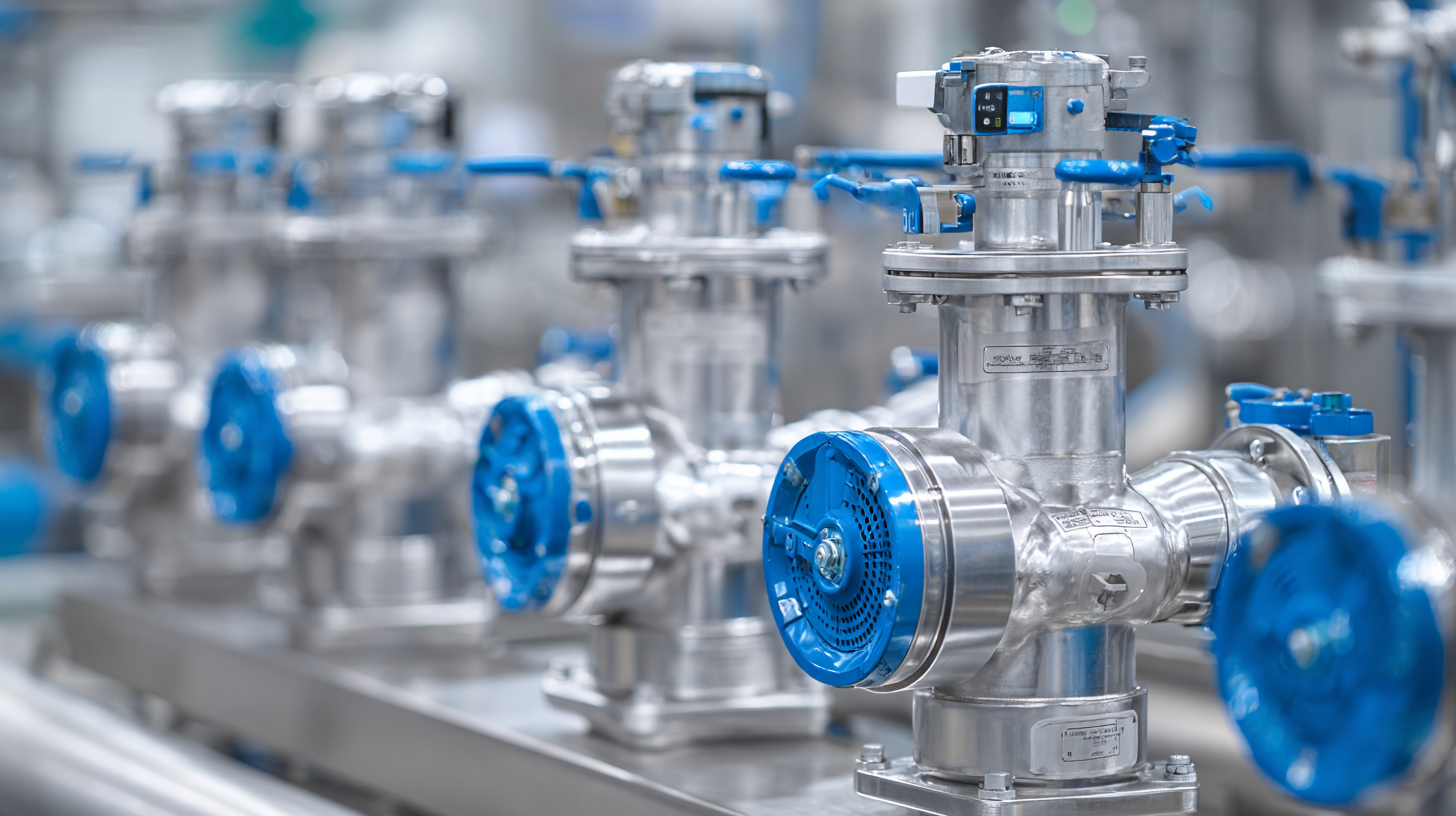

How to Choose the Right Diaphragm Valves for Your Industrial Applications

Choosing the right diaphragm valves for your industrial applications is a critical decision that can significantly influence the efficiency and reliability of your operations. Diaphragm valves, known for their unique design and ability to handle a variety of fluids, offer distinct advantages such as leak prevention and ease of maintenance. However, with numerous options available on the market, selecting the most suitable diaphragm valves can be overwhelming. Understanding the key factors that impact performance—such as material compatibility, pressure rating, and application specifics—is essential for making an informed choice. In this guide, we will provide valuable tips and insights to help you navigate the complexities of diaphragm valve selection, ensuring that you choose the right products to meet your operational needs and enhance overall system performance.

Factors Influencing Diaphragm Valve Selection for Industrial Applications

When selecting diaphragm valves for industrial applications, several critical factors come into play. Understanding the specific requirements of your system is paramount. This includes considerations such as the type of fluid being handled, pressure and temperature ranges, and the desired flow rate. Each of these elements can significantly influence the performance and longevity of the diaphragm valve.

**Tips:** Always ensure that the diaphragm material is compatible with the fluid to prevent premature wear or failure. Additionally, consider the valve's size carefully; an oversized valve can lead to inefficiencies, while an undersized valve may not handle the required flow.

Another important aspect is the operating environment. Factors such as exposure to corrosive substances, temperature fluctuations, and physical space constraints should guide your selection. For example, a valve used in a steam application will require materials that withstand high temperatures and pressures.

**Tips:** Be proactive about maintenance requirements. Some diaphragm valves are easier to service and repair than others, so choosing a model that allows for straightforward access will save time and costs in the long run. Prioritize suppliers that offer comprehensive support and maintenance resources.

How to Choose the Right Diaphragm Valves for Your Industrial Applications

| Application Type | Material | Pressure Rating | Temperature Range | Media Type | Size |

|---|---|---|---|---|---|

| Chemical Processing | PTFE | 150 psi | -40°F to 180°F | Acids and Bases | 1" to 2" |

| Water Treatment | EPDM | 200 psi | 32°F to 150°F | Water | 2" to 4" |

| Pharmaceutical | Silicone | 100 psi | -10°F to 250°F | Biological Fluids | 0.5" to 3" |

| Food Processing | Rubber | 125 psi | 30°F to 180°F | Food Products | 1" to 3" |

| HVAC Systems | PVC | 80 psi | 15°F to 140°F | Air and Gas | 2" to 6" |

Key Specifications to Consider: Pressure, Temperature, and Material Compatibility

When selecting diaphragm valves for industrial applications, it's essential to focus on key specifications such as pressure, temperature, and material compatibility. Pressure ratings determine the maximum pressure that a valve can handle without risk of failure. It's crucial to match the valve’s pressure specifications with the operational requirements of your system, ensuring safety and longevity.

Temperature is another critical factor. Different valve designs are built to withstand various temperature ranges, which directly affect their performance and material integrity. For instance, high-temperature applications may necessitate valves constructed from specially engineered polymers or metals that can endure thermal stress. Always check the manufacturer’s temperature ratings to avoid unexpected failures.

**Tips:** Before finalizing your valve choice, consider the chemical compatibility of materials with the fluids being transported. Some materials may degrade over time when exposed to certain chemicals, leading to leaks or valve failure. Always consult with your supplier for compatibility charts. Additionally, think about the installation space and configuration of the valve; some designs may be more suitable for tight spaces than others.

Understanding Different Diaphragm Valve Designs: Weir vs. Straight-Through Types

When selecting diaphragm valves for industrial applications, understanding the differences between weir and straight-through designs is crucial. Weir diaphragm valves feature a raised seat that creates a weir effect, causing the fluid to change direction as it flows through the valve. This design is particularly advantageous for controlling flow in applications that handle slurries or fluids with a high level of particulate matter, as it minimizes sediment buildup and allows for better flow regulation. The weir design also tends to offer a tighter seal, making it suitable for applications requiring leak-proof performance.

In contrast, straight-through diaphragm valves have a more direct flow path, allowing fluids to pass through with minimal resistance. This design is ideal for applications where a high flow rate is necessary and is often preferred for clean, low-viscosity fluids. The straight-through configuration reduces the turbulence of the fluid, thus preserving its characteristics. However, this design may be less effective in handling viscous fluids or those with solid particles, as it could lead to blockages or increased wear on the valve components. Understanding these differences will help in making an informed decision based on the specific requirements of your industrial processes.

Comparison of Diaphragm Valve Types in Industrial Applications

This chart compares two types of diaphragm valves commonly used in industrial applications: Weir type and Straight-Through type. The data represents the percentage of typical applications where each design is preferred. As observed, Weir type valves are utilized in about 60% of applications compared to 40% for Straight-Through type valves, indicating a strong preference for Weir design in many industrial scenarios.

Analyzing Industry-Specific Standards and Certifications for Diaphragm Valves

When selecting diaphragm valves for industrial applications, understanding industry-specific standards and certifications is crucial. Different sectors, such as pharmaceuticals, food processing, and chemical manufacturing, have unique requirements that dictate the selection of diaphragm valves. For example, valves used in the pharmaceutical sector must comply with stringent regulations like the FDA and cGMP standards to ensure product purity and safety. Similarly, valves in food applications may need to meet 3A Sanitary Standards to ensure hygienic processing.

**Tips:**

When researching diaphragm valves, consider the specific regulations that apply to your industry. Always verify that the valve you choose is certified by recognized bodies, which can typically be found in the product specifications. This not only ensures compliance but also enhances reliability and performance.

Another important factor to consider is the materials used in the diaphragm valves. Different materials offer varying levels of resistance to chemical exposure and temperature fluctuations. Checking for certifications related to material safety, such as NSF or CE marks, can provide peace of mind that the valve will perform well in demanding industrial environments.

Staying informed about these standards can significantly impact your operational efficiency and safety. Take the time to evaluate all certifications and ensure they align with your specific application requirements.

Cost-Benefit Analysis: Long-Term Savings with Quality Diaphragm Valve Selection

When selecting diaphragm valves for industrial applications, it's essential to perform a thorough cost-benefit analysis to ensure long-term savings. Quality diaphragm valves, while potentially more expensive upfront, often lead to reduced maintenance and operational costs. They are designed to withstand harsh conditions and resist wear, which minimizes downtime due to replacements or repairs. Over time, the reliability of a well-chosen valve translates into significant savings in both labor and replacement parts.

Additionally, investing in high-quality diaphragm valves can enhance process efficiency. Many superior models come with features that improve flow control and reduce the risk of leaks and product contamination. By considering the total lifetime cost rather than just initial purchase price, industries can better evaluate the true economic impact of their valve choices. Ultimately, thoughtful selection based on a comprehensive cost-benefit analysis will not only lead to immediate fiscal advantages but also enhance overall productivity and reliability in industrial operations.

Related Posts

-

Understanding the Role of Diaphragm Valves in Modern Industrial Applications

-

The Future of Diaphragm Valves Set to Transform Fluid Control Technologies

-

Understanding the Types of Tubing Fittings for Optimal Performance

-

How to Select the Right Pump Valves for Your Industrial Applications

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

10 Best Plug Valves: Unlocking 20% More Efficiency in Your Piping Systems