How to Choose the Right Steel Fittings for Your Project?

When embarking on a construction or engineering project, choosing the right fittings steel is crucial. Expert John Anderson, a renowned authority in the fittings steel industry, emphasizes, "The right steel fittings can make or break a project." This statement highlights the importance of selecting the appropriate fittings. The choice affects not only the integrity of the structure but also its overall success.

Many factors come into play when selecting fittings steel. Different applications require varying types of steel, sizes, and finishes. It’s vital to consider the specific conditions of your project. For example, will the fittings be exposed to extreme temperatures or corrosive environments?

However, the selection process can be overwhelming. Many individuals overlook essential details. Mistakes, such as choosing mismatched sizes or inappropriate materials, can lead to setbacks. It's important to reflect on past experiences and learn from them. Attaining the right balance of quality and cost is not always straightforward.

Understanding the Different Types of Steel Fittings Available

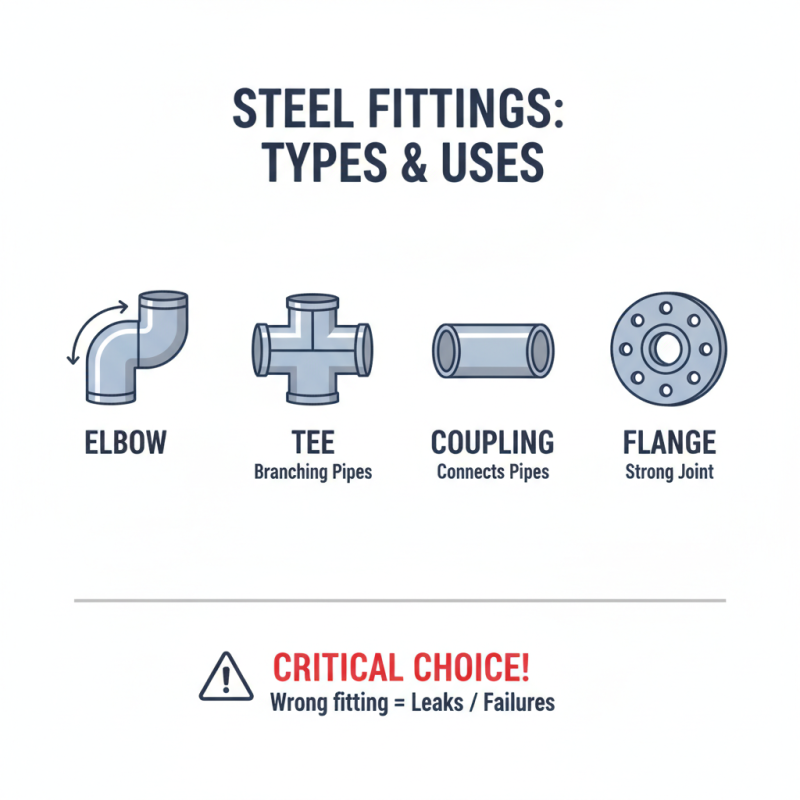

When choosing steel fittings for your project, it's essential to understand the various types available. Steel fittings come in many shapes and sizes. Common types include elbows, tees, couplings, and flanges. Each type serves a specific purpose, whether it’s to change direction, connect pipes, or create a strong joint. Not all fittings are equal, and the wrong choice can lead to leaks or structural failures.

Material is crucial when selecting fittings. Some are made from stainless steel, while others are carbon steel. Stainless steel is resistant to corrosion but can be more expensive. Carbon steel, though stronger, might rust without proper treatment. Consider the environment of your project. Will it face water exposure? High temperatures? These factors can influence your choice.

Installation can also be tricky. Some fittings are easy to work with, while others require specialized skills. Mistakes can be costly. Take time to research and even ask professionals for advice. Understand that the right fitting can make or break your project. A hasty decision may lead to troubles down the line. Ensure you evaluate your options carefully.

Key Factors to Consider When Selecting Steel Fittings

Choosing the right steel fittings requires careful consideration. It’s crucial to assess the project’s requirements. Think about the environment where the fittings will be used. Will they face moisture? Corrosion is a concern in such cases. Selecting corrosion-resistant options could save future maintenance costs.

The size and compatibility with existing piping are also key factors. A mismatch can lead to leaks or failures. Always double-check measurements before purchasing. It’s often tempting to go with the cheapest option. However, cheaper materials might not last, leading to more expenses later on. Inspect quality ratings and construction methods to ensure longevity.

Do not overlook installation ease. Some fittings are more complex than others. Complicated fittings can lead to delays. Consider the overall design and accessibility during installation. Engaging with experts can provide insights that save time and money. Reflect on your choices and be open to adjustments; this is part of the process.

Assessing the Compatibility of Steel Fittings with Your Project Materials

When selecting steel fittings, assessing compatibility is crucial. The right fitting must align with the project materials. For example, carbon steel is often paired with other carbon steel components. This pairing is fundamental to ensure strength and reliability. Studies show that improper material compatibility can lead to failures. A report by the Steel Founders' Society indicates that up to 30% of fitting failures stem from material mismatches.

Consider the environment as well. Exposure to moisture may require stainless steel for corrosion resistance. A compatibility matrix can help determine the durability of fittings. Yet, many overlook this important step, often leading to costly mistakes. The associated failure rate in such scenarios can exceed 20%, according to industry analyses.

Additionally, take note of joint designs. Some joints require specific fitting types to ensure leakage prevention. However, the complexity of certain projects can lead to confusion. Rushing decisions without thorough evaluation results in subpar fittings. Review project specifications before settling on materials. Adjusting the selection process can save future headaches.

How to Choose the Right Steel Fittings for Your Project?

This chart illustrates the compatibility of different types of steel fittings with various project materials based on their strength ratings and common applications.

Evaluating Quality Standards and Certifications for Steel Fittings

Choosing the right steel fittings requires understanding quality standards. Industry certifications ensure the reliability and safety of your fittings. Look for ISO 9001 certification, which indicates a strong commitment to quality management. According to industry data, fittings that meet ASTM standards have a longer lifespan in construction projects.

Tip: Always ask suppliers for quality documentation. Evaluating the standards guarantees that the fittings will perform under pressure.

Quality doesn't stop at certifications. Consider the manufacturing process too. Steel fittings should undergo rigorous testing, such as pressure and impact tests. Reports highlight that fittings tested for extreme conditions provide greater safety margins.

Tip: Check if the supplier provides testing results. It reflects their commitment to transparency and quality.

Remember, not all suppliers adhere to high standards. Scrutinize backgrounds and customer reviews. Quality may look good on paper, but what about real-life performance? Investing time here can prevent future headaches.

Cost Considerations and Budgeting for Steel Fittings in Your Project

When budgeting for steel fittings, it’s essential to understand the material costs. Prices can fluctuate based on market conditions. Always check for local suppliers to compare costs effectively. Buying in bulk can reduce the overall price per unit, leading to significant savings.

Consider the project’s scope and complexity. Large projects may require more fittings, which adds to the cost. Unforeseen changes can increase expenses. It's vital to anticipate potential needs. Sometimes, overspending on high-grade materials seems tempting but might not always be necessary. Weigh the benefits versus the budget constraints carefully.

Installation expenses should also be part of the equation. Costs can swell if skilled labor is required. This often involves planning for extra time or tools, which can lead to delays. Take a moment to reflect on potential alternatives. Is there a simpler design? Are there ways to streamline the process? Addressing these questions can help you stay within budget while accomplishing your goals.

How to Choose the Right Steel Fittings for Your Project? - Cost Considerations and Budgeting for Steel Fittings in Your Project

| Fitting Type | Material Grade | Unit Cost ($) | Typical Applications | Estimated Lifespan (Years) |

|---|---|---|---|---|

| Elbow | ASTM A234 Gr. WPB | 2.50 | Piping systems, HVAC | 30 |

| Tee | ASTM A234 Gr. WPB | 3.00 | Water, oil, and gas pipelines | 30 |

| Reducer | ASTM A234 Gr. WPB | 3.50 | Fluid transfer systems | 25 |

| Flange | ASTM A105 | 4.00 | Industrial piping systems | 30 |

| Cap | ASTM A234 Gr. WPB | 1.75 | Pipelines, end closures | 20 |

Related Posts

-

7 Essential Insights about Steel Fittings for Optimal Performance

-

Top 5 Essential Steel Fittings: Maximizing Durability and Performance in Industrial Applications

-

Top Steel Fittings Types You Need to Know in 2026?

-

Exploring Fittings Steel Market Growth at the 138th Canton Fair in 2025 with Key Industry Insights

-

Understanding the Types of Tubing Fittings for Optimal Performance

-

Top 10 Essential Tubing Fittings for Your Next Project