How to Choose the Right Sanitary Ball Valves for Your Applications

When it comes to ensuring the cleanliness and efficiency of fluid transfer systems, the selection of appropriate sanitary ball valves plays a critical role. Sanitary ball valves are specifically designed for applications that require high hygiene standards, making them essential in industries such as food processing, pharmaceuticals, and biotechnology. Choosing the right type of sanitary ball valve can significantly impact both the performance and safety of these systems.

In this guide, we will explore the key factors to consider when selecting sanitary ball valves for your specific applications. Understanding the materials, connections, and certifications associated with these valves is crucial for guaranteeing compliance with industry regulations and ensuring optimal functionality. By delving into the unique characteristics of various sanitary ball valve designs and their applications, you will be equipped to make informed decisions that maintain the integrity of your fluid systems. With the right knowledge, you can enhance efficiency and uphold the sanitary standards essential for your operations.

Understanding the Basics of Sanitary Ball Valves

Sanitary ball valves are essential components in various industries, particularly in food processing, pharmaceuticals, and biotechnology, where cleanliness and hygiene are paramount. Understanding the basics of these valves is crucial for making informed decisions in your applications. Sanitary ball valves are designed with smooth surfaces and a simple construction that allows for easy cleaning and maintenance. They typically have a full bore design, ensuring that the flow path is uninterrupted, which minimizes the risk of contamination.

When selecting sanitary ball valves, consider the materials used in their construction. Stainless steel is the preferred choice due to its corrosion resistance and ability to withstand high-pressure conditions. Additionally, the valve's seals and gaskets must be compatible with the fluids being handled, as well as meet stringent regulatory standards.

Tips: Always check the certification of the valves for compliance with industry standards. Look for valves that offer features like quick-disconnects for easier maintenance, and consider the mounting options available for flexibility in installation. Finally, take into account the operating temperature and pressure limits of your application to ensure optimal performance and longevity of the valves.

Key Factors to Consider When Selecting Sanitary Ball Valves

When selecting sanitary ball valves for your applications, several key factors need to be considered to ensure optimal performance and compatibility. First, assess the material construction of the valves. Common materials include stainless steel, plastic, or other alloys, each with unique properties suited for different environments and fluid types. The choice of material can impact not only the valve’s durability but also its resistance to corrosion and contamination, which is critical in sanitary applications.

Another essential factor is the valve size and pressure rating. Ensure that the valve can handle the flow rates and pressures required for your system. An undersized valve may lead to insufficient flow, while one that’s too large could create unnecessary turbulence. It is also important to consider the connection type, whether it is tri-clamp, threaded, or welded, as this affects installation and maintenance requirements.

**Tips:** When selecting a valve, always refer to the specifications provided by the manufacturer to verify compatibility with your existing systems. Furthermore, consulting with industry experts can provide valuable insights based on your specific application, ensuring that you choose the most suitable valve for your needs. Lastly, always prioritize valves that are easy to clean and maintain to meet hygiene standards effectively.

Sanitary Ball Valves Selection Factors

Material Selection for Sanitary Ball Valves: What You Need to Know

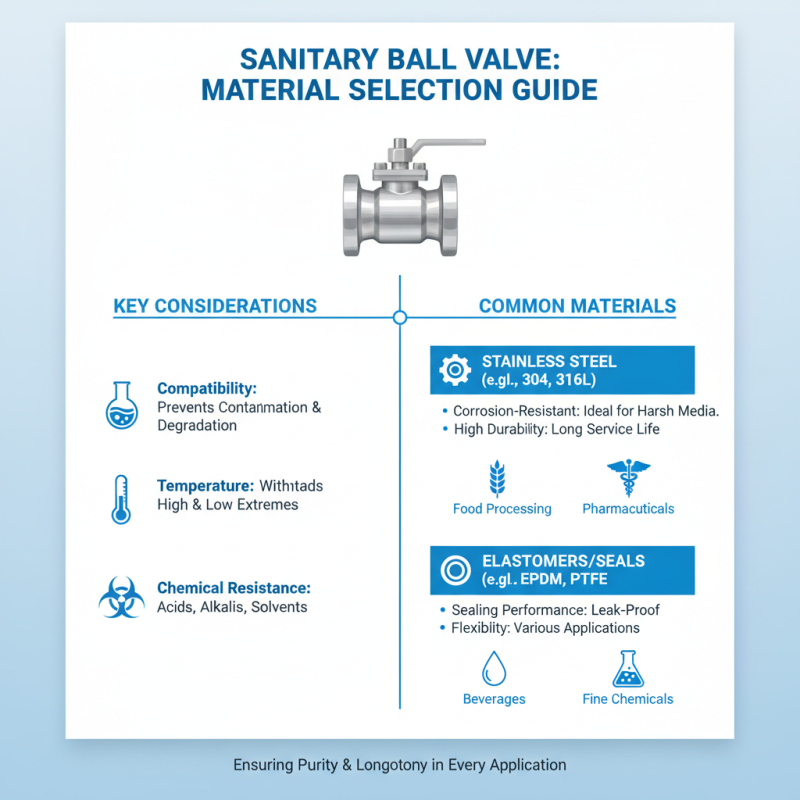

When selecting sanitary ball valves for various applications, material selection is a crucial factor that can significantly impact the valve's performance and longevity. The materials used in sanitary ball valves must be compatible with the substances they will handle, ensuring that there is no contamination or degradation due to chemical reactions. Common materials include stainless steel, which is favored for its corrosion resistance and ability to withstand high temperatures, making it suitable for both food processing and pharmaceutical industries.

In addition to stainless steel, plastic materials like PVC or PTFE can be considered for specific applications where chemical resistance is paramount and where the process temperature is lower. It is essential to evaluate the nature of the media, including pH levels, temperature ranges, and potential exposure to harsh environments, to ensure that the selected material will maintain its integrity and functionality over time. By carefully considering these factors, manufacturers can select the right sanitary ball valves that meet the specific requirements of their processing environments, ultimately ensuring both efficiency and safety in their operations.

Evaluating Compatibility with Your Application’s Specific Requirements

When selecting the right sanitary ball valves for your applications, it is crucial to evaluate their compatibility with your specific requirements, considering factors such as material compatibility, pressure ratings, and temperature tolerance. According to a report by MarketsandMarkets, the global sanitary valves market is expected to reach $3.14 billion by 2025, driven by the burgeoning demand in the food and beverage, pharmaceutical, and chemical industries. Each sector mandates strict compliance to safety and sanitation standards, necessitating careful selection of valves that meet operational criteria.

Material compatibility is often the first consideration in this selection process. For instance, stainless steel is frequently preferred for its corrosion resistance and durability, particularly in environments exposed to harsh chemicals or high temperatures. A study by the International Society for Pharmaceutical Engineering indicates that the right material choice can reduce maintenance costs by up to 30%, highlighting the financial benefits of thorough compatibility evaluations. Furthermore, assessing the required pressure and temperature ratings is vital; improper selections can lead to premature valve failure, safety hazards, and costly downtimes. It is recommended to consult industry standards and guidelines to ensure that chosen valves align with the unique operational demands of your applications, thus enhancing both performance and safety.

How to Choose the Right Sanitary Ball Valves for Your Applications

| Criterion | Considerations | Examples |

|---|---|---|

| Material Compatibility | Ensure valve materials resist corrosion and contamination. | 316 Stainless Steel, EPDM Seals |

| Size and Connection Type | Choose the right diameter and connection style for your piping system. | 1", 2", Tri-Clamp, Threaded |

| Pressure Rating | Consider the working pressure of your system. | 150 psi, 300 psi |

| Temperature Range | Ensure capabilities meet application temperature requirements. | -20°F to +250°F |

| Cleanliness Level | Evaluate requirements for sanitation levels in applications. | FDA approved, 3A standards |

| Flow Characteristics | Choose valves that optimize flow rates for your application. | Full Port, Reduced Port |

Installation and Maintenance Tips for Optimal Valve Performance

When it comes to ensuring optimal performance of sanitary ball valves in various applications, proper installation and maintenance are crucial. According to a report by the Fluid Control Institute, improper installation is a leading cause of valve failure, contributing to over 25% of maintenance issues reported in industrial settings. To mitigate this risk, valves should be installed in accordance with manufacturer specifications, carefully considering the flow direction and ensuring that all connections are secure. Using appropriate tools and techniques can prevent damage to valve seats and seals, which are vital for maintaining hygienic standards in sanitary applications.

Regular maintenance is equally important for the longevity and functionality of sanitary ball valves. A study by the International Society of Automation emphasizes that routine inspections can significantly reduce the likelihood of unexpected downtime caused by valve malfunction. Operators should develop a maintenance schedule that includes checks for leaks, wear, and correct functionality. Employing appropriate cleaning protocols designed for sanitary equipment not only ensures compliance with industry standards but also extends the life of the valve components. By prioritizing both correct installation and consistent maintenance, facilities can achieve reliable performance and uphold the stringent hygiene requirements necessary for industries such as food and beverage, pharmaceuticals, and biotechnology.

Related Posts

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries

-

The Ultimate Guide to Choosing Eco-Friendly Water Fittings for Sustainable Living

-

Essential Tips for Choosing the Right Brewery Fittings for Your Brewing Setup

-

7 Essential Features to Look for in Sanitary Fittings

-

How to Choose the Right Stainless Sanitary Fittings for Your Project