Why Choosing the Right Pump Fittings is Crucial for Your System Performance

In the complex world of fluid dynamics, the importance of selecting the right pump fittings cannot be overstated. According to renowned industry expert Dr. Emily Carter, a leading authority in hydraulic engineering, “The effectiveness of a pumping system directly hinges on the quality and compatibility of its fittings.” This insight underscores the fundamental role that pump fittings play in overall system performance.

The careful selection of pump fittings is crucial not only for maximizing efficiency but also for ensuring safety and longevity of the equipment. Each fitting must complement the pump’s specifications, such as pressure and flow rates, while also being compatible with the fluid being transported. As systems vary greatly in design and application, understanding the nuances of pump fittings can significantly enhance operational reliability and reduce maintenance costs.

Ultimately, the decision-making process surrounding pump fittings should never be taken lightly. Whether in industrial settings or smaller-scale operations, the ramifications of inadequate fittings can lead to severe performance issues and costly downtime. Thus, investing time and resources into selecting the correct pump fittings is not just a best practice but a necessity for achieving optimal system performance.

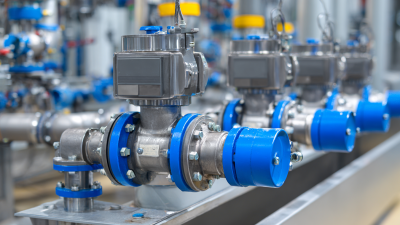

Importance of Pump Fittings in Fluid Transfer Systems

When it comes to fluid transfer systems, the significance of pump fittings cannot be overstated. These components may often go unnoticed, yet they play a crucial role in ensuring that the fluid moves efficiently and safely through the system. Quality fittings help to avoid leaks, reduce maintenance costs, and enhance overall system performance, ultimately contributing to a more sustainable operation. The right selection of pump fittings can therefore have a substantial impact on your operational efficiency.

Tips: Always choose fittings that are compatible with the materials being pumped to avoid chemical reactions that could degrade the fittings or the fluid. Regularly inspect fittings for wear and tear to prevent unexpected failures. Additionally, consider using fittings with a proven track record in similar applications for better reliability.

Innovation in pump fitting technology continues to evolve, addressing the various challenges faced in fluid transfer systems. Closed transfer systems, for example, are now available to improve safety and efficiency when handling hazardous materials, such as pesticides. These technological advancements reinforce the vital role pump fittings play in maintaining high standards in fluid transfer operations, showcasing the importance of selecting the right components for enhanced performance.

Types of Pump Fittings and Their Applications

When selecting pump fittings, understanding the various types and their applications is essential for optimizing system performance. There are several categories of pump fittings, including threaded, flanged, and slip-on fittings, each designed to cater to specific operational needs. For instance, threaded fittings are commonly used in applications where space is limited, allowing for tight connections without the need for additional tools. Flanged fittings, on the other hand, provide robust mechanical connections, making them ideal for high-pressure systems typically found in industrial settings.

Recent advancements in technology, particularly within the agricultural sector, highlight the importance of efficient pump fittings. According to industry reports, incorporating smart technology in agricultural irrigation systems can enhance efficiency and sustainability while significantly boosting crop yields. The demand for high-performance liquid chromatography (HPLC) systems also underscores the necessity for precise pump fitments, as they directly influence the accuracy of chemical processing. Ensuring compatibility among various components not only enhances operational efficiency but also prevents costly downtimes, emphasizing the critical role of selecting the right pump fittings in any system.

Types of Pump Fittings and Their Applications

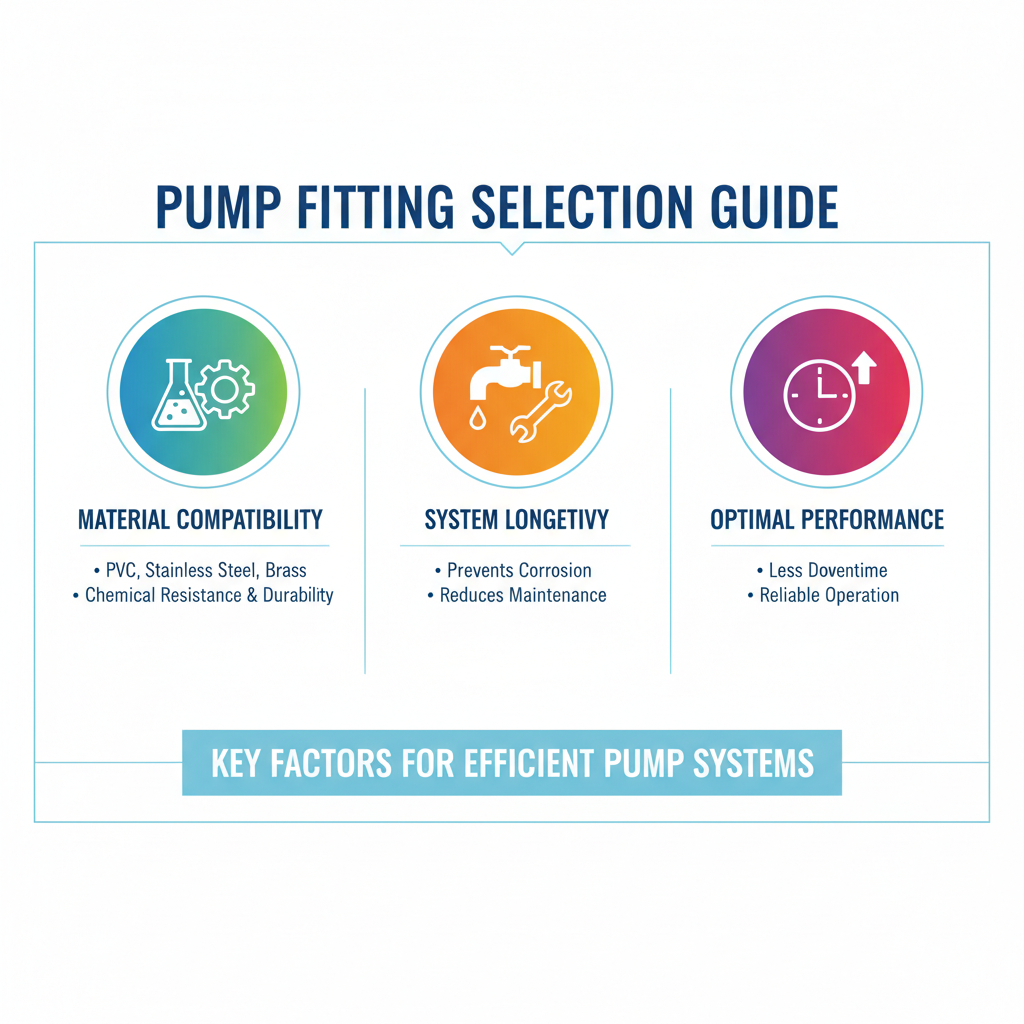

Factors to Consider When Selecting Pump Fittings

When selecting pump fittings, several critical factors come into play to ensure optimal system performance. Firstly, compatibility with the pump material is essential. Different materials such as PVC, stainless steel, or brass exhibit varying chemical resistances and durability. Choosing the right material helps avoid corrosion and ensures longevity, ultimately reducing maintenance costs and system downtime.

Another significant consideration is the fitting size and configuration. Proper sizing affects flow rates and can prevent issues like cavitation or pressure drops within the system. It’s also crucial to analyze the system's pressure ratings and temperature ranges, as fittings must withstand the operational conditions without leaking or failing. Additionally, it’s important to factor in installation ease and accessibility, which can influence future maintenance and repairs. Ensuring that your pump fittings meet these criteria can lead to increased efficiency and reliability in your pumping system.

Impact of Improper Fitting Choices on System Efficiency

Choosing the right pump fittings is essential for ensuring optimal system performance, as improper fitting choices can significantly affect efficiency. When fittings do not match the system specifications, it can lead to increased flow resistance, leaks, and pressure drops. This inefficiency not only wastes energy, leading to higher operational costs, but can also cause undue stress on the pump and other components, ultimately shortening their lifespan.

Furthermore, improper fittings may disrupt the fluid dynamics within the system. For example, sharp bends or mismatched diameters can create turbulence, reducing the fluid's ability to flow smoothly. This can result in uneven flow rates and potential cavitation, which further compromises the pump’s performance. By investing time and resources into selecting the appropriate fittings, operators can enhance system reliability, improve energy efficiency, and maintain optimal performance throughout the lifespan of the pump system.

Maintenance Tips for Ensuring Optimal Pump Fitting Performance

Maintaining optimal pump fitting performance is essential for ensuring the longevity and efficiency of your pumping system. Regular maintenance not only prevents potential failures but also enhances overall system efficiency. One critical tip is to schedule routine inspections of your pump fittings. Look for signs of wear, corrosion, or improper alignment, as these issues can significantly affect performance. Addressing small problems early can save you from costly repairs or system downtime.

Another vital maintenance tip is to ensure proper sealing and connections. Loose fittings or damaged seals can lead to leaks, which decrease system efficiency and can cause damage to surrounding components. Always check the fittings for tightness and replace any worn seals to maintain the integrity of your system. Lastly, consider using compatible materials when replacing fittings. Using mismatched materials can lead to chemical compatibility issues and accelerated wear. By following these maintenance tips, you can ensure that your pump fittings perform at their best, contributing to the overall effectiveness of your pumping system.

Why Choosing the Right Pump Fittings is Crucial for Your System Performance - Maintenance Tips for Ensuring Optimal Pump Fitting Performance

| Fitting Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Maintenance Frequency |

|---|---|---|---|---|

| PVC Fitting | Polyvinyl Chloride | 150 | 32 to 140 | Annually |

| Copper Fitting | Copper | 1000 | -40 to 250 | Biannually |

| Stainless Steel Fitting | Stainless Steel | 1500 | -50 to 300 | Yearly |

| Brass Fitting | Brass | 800 | -30 to 250 | Yearly |

| Aluminum Fitting | Aluminum | 600 | -40 to 200 | Every six months |

Related Posts

-

How to Choose the Right Stainless Steel Fittings: Key Factors and Industry Insights for Optimal Performance

-

How to Choose the Right Diaphragm Valves for Your Industrial Applications

-

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries

-

How to Choose the Right Ball Valve for Your Application

-

Understanding the Benefits of Stainless Steel Ball Valves for Industrial Applications

-

10 Best Tubing Fittings for Your Plumbing Projects in 2023