How to Choose the Best Stainless Steel Ball Valves for Your Needs

Choosing the right stainless steel ball valves for your needs is essential for ensuring the efficiency and reliability of various industrial applications. According to a report by MarketsandMarkets, the global ball valve market is projected to reach $11.46 billion by 2026, driven by the growing demand across sectors such as oil and gas, water and wastewater treatment, and power generation. This shifting landscape underscores the importance of selecting high-quality stainless steel ball valves that meet specific operational requirements.

As noted by industry expert Dr. Emily Johnson, a prominent figure in fluid control technologies, "The choice of stainless steel ball valves can significantly affect the performance and longevity of any system." Her insights highlight the critical role that material selection plays in valve efficacy, especially in environments that demand high durability and corrosion resistance. Understanding the various types, specifications, and applications of stainless steel ball valves will empower professionals to make informed decisions, ultimately optimizing both performance and safety in their operations.

Understanding Stainless Steel Ball Valves and Their Applications

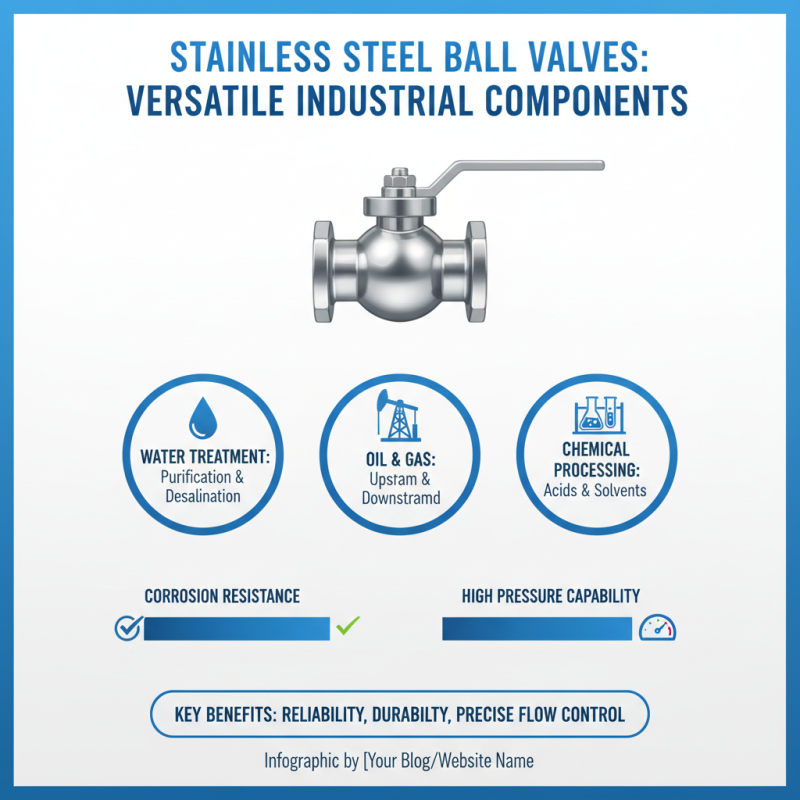

Stainless steel ball valves are versatile components widely used in various industries due to their excellent resistance to corrosion and ability to maintain high pressure. Understanding their applications is essential for selecting the right valve for specific needs. They are commonly utilized in sectors such as water treatment, oil and gas, and chemical processing, where reliability and durability are paramount. The smooth, spherical design of the valve allows for quick and efficient flow control, making them ideal for systems that require precise regulation of fluids.

In addition to their practical applications, stainless steel ball valves are favored for their aesthetic appeal and easy maintenance. They are especially beneficial in environments where hygiene and cleanliness are crucial, such as food and beverage processing facilities. Their robust construction ensures a long lifespan, reducing the frequency of replacements and maintenance efforts. When choosing a ball valve, it is important to consider factors such as the size, pressure rating, and temperature range, ensuring that the valve will perform effectively within the specific operational parameters of the intended application.

Key Factors to Consider When Choosing Stainless Steel Ball Valves

When selecting stainless steel ball valves, there are several key factors to consider to ensure optimal performance and longevity. Firstly, the valve's material composition is crucial; austenitic stainless steels, such as 304 and 316, are widely recognized for their corrosion resistance and durability in various environments. According to a report by Grand View Research, the global stainless steel market is projected to reach $170.37 billion by 2027, underscoring the importance of high-quality materials in valve construction to meet industrial demands.

Another significant factor is the valve's size and pressure rating, which must align with the specific application requirements. Ensuring the correct diameter and pressure class is vital to prevent leaks and ensure efficient flow control. The American Society of Mechanical Engineers (ASME) provides guidelines for pressure-temperature ratings, which can be critical in selecting the right valve for applications in the oil and gas industry, where specifications can be stringent. Additionally, understanding the flow characteristics is essential; ball valves typically offer excellent flow rates with minimal pressure loss, making them ideal for a variety of workflows.

Ultimately, when selecting the best stainless steel ball valves, evaluating these critical factors—material use, size, pressure rating, and flow efficiency—can lead to improved operational reliability and cost-effectiveness in industrial settings. Utilizing data from industry reports can further aid in making informed choices tailored to specific needs.

Different Types of Stainless Steel Ball Valves and Their Features

When selecting the best stainless steel ball valves for specific applications, understanding the various types and their features is crucial. Stainless steel ball valves are primarily classified into two categories: full port and reduced port. Full port valves have a wider bore that matches the diameter of the piping, which allows for minimal pressure drop and a greater flow capacity. According to industry analysis, full port valves can improve system efficiency by up to 20% compared to reduced port models, making them ideal for applications that require maximum flow rate.

Another critical distinction lies in the valve design, which can be either two-way or three-way. Two-way valves are standard and provide a simple on/off function, while three-way valves are essential for diverting or mixing flow between different pipelines. Reports from the Flow Control Industry indicate that three-way valves account for approximately 30% of the overall market for ball valves, underscoring their importance in complex piping systems. Additionally, considerations such as seat material, which can affect sealing performance and longevity, should also be examined to ensure the valve meets the operational demands of the environment it will be installed in.

Comparison of Different Types of Stainless Steel Ball Valves

Maintaining and Troubleshooting Stainless Steel Ball Valves

Maintaining and troubleshooting stainless steel ball valves is essential to ensure optimal performance and longevity. Regular maintenance protocols can significantly enhance the lifespan of these components, reducing the likelihood of costly replacements. According to a report by the American Society of Mechanical Engineers (ASME), regular inspections and maintenance can increase valve life by up to 70%. Key maintenance practices include routine cleaning, lubrication, and checking for signs of wear and corrosion which can compromise the valve's integrity. Utilizing non-abrasive cleaners and ensuring appropriate lubrication can prevent the buildup of debris and facilitate smooth operation.

When faced with operational issues such as leaks or failure to open or close, it is crucial to conduct a thorough troubleshooting process. A study from the Valve Manufacturers Association (VMA) suggests that improper installation accounts for approximately 30% of valve malfunctions. Therefore, ensuring correct alignment and torque settings during installation is paramount. Additionally, technicians should inspect the seals and gaskets for damage, as these components play a vital role in preventing leaks. If issues persist, it may be necessary to disassemble the valve for a more comprehensive evaluation, particularly focusing on internal components for debris or wear that could hinder functionality. Implementing these maintenance and troubleshooting practices can significantly enhance the efficiency and reliability of stainless steel ball valves in various applications.

Evaluating Suppliers and Making Informed Purchases of Valves

When selecting stainless steel ball valves, evaluating suppliers is crucial to ensure that you are making informed purchases that meet your operational needs. It's essential to consider the supplier's reputation, product quality, and customer service track record. A recent industry report indicated that 70% of manufacturers prioritize long-term partnerships with suppliers who demonstrate consistent quality and reliability in their products. Therefore, researching supplier certifications, such as ISO 9001, and reviewing their manufacturing processes can offer insights into the quality of their valves.

Moreover, the purchasing decision should be supported by data from trusted sources. Studies have shown that the total cost of ownership (TCO) of valves can vary significantly based on factors such as material selection, maintenance requirements, and lifespan. For instance, stainless steel ball valves typically offer a longer lifespan in corrosive environments compared to plastic alternatives, which can translate into lower maintenance costs over time. Engaging in thorough market research and tapping into industry reports can provide valuable comparisons to ensure that the selected valves not only meet immediate needs but also contribute to overall cost efficiency in the long run.

Related Posts

-

Understanding the Benefits of Stainless Steel Ball Valves for Industrial Applications

-

How to Choose the Right Diaphragm Valves for Your Industrial Applications

-

The Ultimate Guide to Choosing the Right Ball Valves for Your Plumbing Projects

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

Top Strategies for Enhancing Performance with Fittings Valves

-

The Complete Guide to Choosing the Right Stainless Steel Fittings for Your Plumbing Projects