What is a butterfly valve and how does it work?

Butterfly valves are essential components in various industrial applications. They control fluid flow efficiently. Understanding how these valves work can enhance system performance.

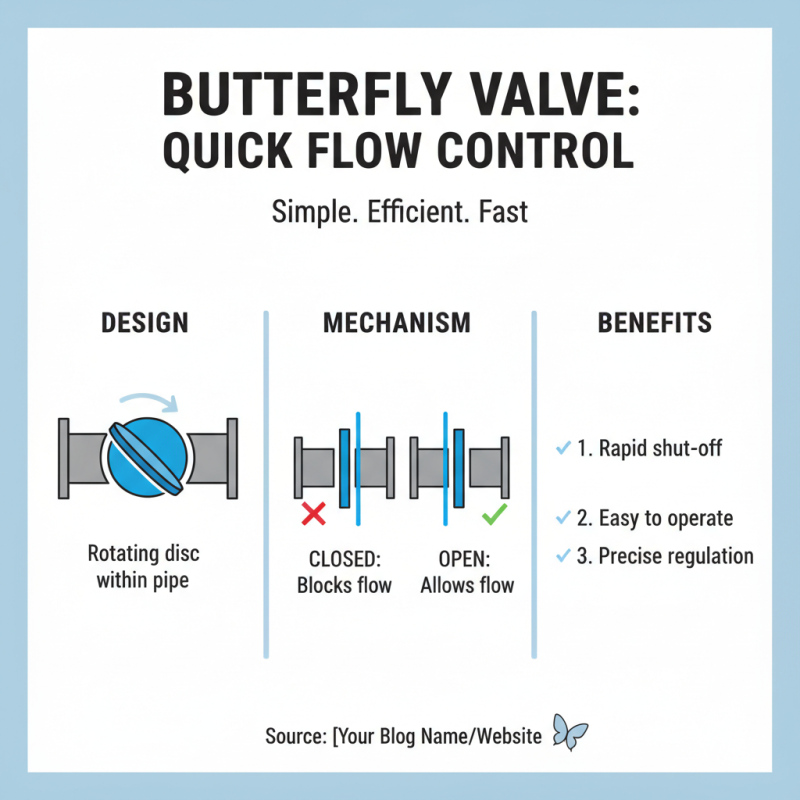

A butterfly valve consists of a disk that pivots to open or close. When the valve is open, fluid flows freely. When closed, the disk blocks the flow. This simple design allows for quick operation. Butterfly valves are often chosen for their compact size and lightweight. However, they may not be suitable for high-pressure applications.

Many industries rely on butterfly valves. They are common in water treatment plants and HVAC systems. Despite their advantages, they can also present challenges. For example, improper installation may lead to leaks. It is crucial to ensure correct fitting and maintenance. This article delves deeper into the workings and applications of butterfly valves.

What is a Butterfly Valve? Definition and General Overview

A butterfly valve is a type of flow control device. It features a disc that rotates around a central axis. This disc opens or closes the flow of liquid or gas within pipes. When turned parallel, the flow is unrestricted. When turned perpendicular, the flow stops. This design allows for quick operation and efficient flow control.

Tips: Regular maintenance is essential. Dust and debris can interfere with the valve's performance. Check for leaks after installation. Address any issues immediately.

These valves are used in various applications. They are common in water supply systems and HVAC systems. Their lightweight design makes them easy to install. However, improper sizing can lead to operational problems. Choosing the right valve for your system is crucial. Oversized valves can cause pressure drops, while undersized valves may restrict flow.

Tips: When selecting a butterfly valve, consider the type of medium. Different materials perform better with specific fluids. Always consult a professional if uncertain.

Butterfly Valve Performance Metrics

This chart illustrates the flow rate and pressure drop characteristics of a butterfly valve under various conditions. The data represents common operational metrics for valve performance in fluid systems.

Key Components and Design Features of Butterfly Valves

Butterfly valves are essential in controlling the flow of liquids and gases. Their design is simple yet effective. The main components include a disc, a shaft, and a body. The disc is the heart of the valve. It rotates around the shaft to open or close the flow path. This movement is typically 90 degrees.

The body of the valve houses all components. It can be made from various materials. Common choices are metal and plastic. The choice depends on the application. Different designs cater to specific pressure and temperature requirements. These components must work smoothly together, ensuring reliability and efficiency.

Tips: Regular maintenance is necessary. Check for any wear or leakage. This ensures optimal performance. Always consider the operating environment. Corrosive materials can affect valve integrity. Understanding these factors is crucial for longevity.

Another aspect to consider is installation. Proper alignment of the valve can prevent future issues. Misalignment may lead to premature wear and failure. Always consult technical guidance or experts when needed. Small oversights now can lead to significant problems later on.

Operating Mechanism: How a Butterfly Valve Controls Flow

A butterfly valve is a simple but effective device used to control the flow of fluids. Its design includes a disc that rotates within the pipe. As the disc turns, it either blocks or allows the fluid to pass. This mechanism provides quick and efficient flow regulation. The rotating action makes it easier to operate than other types of valves.

The operating mechanism is straightforward yet fascinating. When the handle is turned, the disc pivots on a shaft. This rotation creates a narrow opening, allowing fluid to flow through. The position of the disc determines the flow rate. It’s interesting how such a simple motion can control significant fluid volumes. However, improper handling can lead to inefficiencies. Misalignment of the disc can cause leaks or prevent full closure.

Butterfly valves are often chosen for their compact design. They take less space than gate or globe valves. Yet, they are not flawless. Their performance can vary with different mediums. Sediment in the fluid can obstruct the disc's motion. Regular maintenance is essential to ensure they function correctly. Users should remain vigilant about their condition.

Applications of Butterfly Valves in Various Industries

Butterfly valves are widely used in various industries due to their simple design and efficient operation. These valves can control the flow of liquids and gases effectively. In the water supply sector, they regulate the flow in pipelines. Their lightweight design allows for easy installation and maintenance.

In the chemical industry, butterfly valves are crucial. They manage the flow of aggressive chemicals safely. Their durability helps in minimizing leaks and spills. In HVAC systems, these valves control air flow, contributing to energy efficiency.

Tip: Regular maintenance is essential. Check for any wear and tear. A small oversight can lead to bigger issues later.

In the food industry, butterfly valves play a key role. They ensure hygiene and compliance with standards. Their smooth operation prevents contamination in processed foods. It’s important to select the right material for specific applications.

Tip: Avoid using butterfly valves in high-pressure situations. This could lead to failure. Each application is unique, so always assess your needs carefully.

While butterfly valves are versatile, they are not always perfect. In certain conditions, they can create turbulence. This can affect flow rates negatively. Evaluate the specific requirements and limitations of your system before selection.

Performance Metrics: Efficiency and Durability of Butterfly Valves

Butterfly valves are widely used in various industries. Their design allows them to control the flow of liquids and gases effectively. Performance metrics such as efficiency and durability are crucial for their function. These valves are typically lightweight and easy to install. This simplicity can sometimes lead to overlooked aspects in installation.

Efficiency is measured by how well the valve controls flow. A well-designed butterfly valve minimizes pressure loss. However, not all models deliver high efficiency. Some may struggle under specific conditions, such as high temperatures or corrosive fluids. It's important to carefully select the valve type for each application.

Durability hinges on the materials used. Many butterfly valves are made of metal or plastic. Metal valves usually last longer but can be more expensive. Plastic valves are lighter and cost-effective but may wear out more quickly. Operators should periodically inspect valves for signs of wear and corrosion. Neglecting maintenance can lead to performance issues. Such problems can be costly over time, highlighting the need for regular assessments.

Related Posts

-

The Ultimate Guide to Understanding and Choosing Butterfly Valves for Your Industrial Needs

-

Why Water Fittings Are Essential for Every Home and How to Choose Them

-

10 Essential Tips for Choosing Stainless Steel Sanitary Fittings You Can't Ignore

-

10 Best Water Valves for Optimal Flow Control in 2023

-

How to Choose the Best Fittings Sanitary for Your Plumbing Needs

-

Essential Tips for Choosing Valve Fittings for Your Project