What is Brewery Fittings and Why Are They Essential for Craft Beer Production

When delving into the world of craft beer production, one cannot overlook the critical role of brewery fittings. These essential components serve as the backbone of a well-functioning brewery, enabling brewers to efficiently manage the intricate processes involved in brewing. From fermentation tanks and piping systems to valves and fittings, each element contributes not only to the overall functionality but also to the quality of the final product. The right brewery fittings ensure that brewers can maintain optimal conditions for fermentation and storage, allowing for the precise control needed to create distinct and flavorful beers.

Moreover, the proper selection and installation of brewery fittings can significantly impact the scalability and adaptability of brewing operations. As craft breweries grow and evolve, having a robust infrastructure with reliable fittings allows for seamless transitions when increasing production or experimenting with new recipes. In essence, brewery fittings are not just accessories; they are vital hardware that supports innovation and consistency in craft beer brewing. Understanding their importance can lead to enhanced brewing practices and ultimately, a more satisfying experience for both brewers and consumers alike.

What Are Brewery Fittings?

Brewery fittings are essential components used in the brewing process, playing a vital role in ensuring the efficiency and quality of craft beer production. These fittings encompass a wide range of items including hoses, valves, clamps, connectors, and separators. Each of these components serves a specific function, aiding in the transfer of liquids, maintaining pressure, and facilitating the separation of solids from liquids during brewing. The selection of the right fittings is crucial, as they must withstand high temperatures, pressure variations, and the corrosive nature of beer ingredients.

In addition to their functional roles, brewery fittings contribute to the overall hygiene and safety of the brewing environment. Properly installed and maintained fittings help prevent contamination, ensuring that the final product is of the highest quality. Moreover, their design often supports ease of cleaning and maintenance, which is vital in an industry where sanitation standards are paramount. As craft breweries continue to grow in popularity, understanding and utilizing the right brewery fittings is more important than ever for producing exceptional craft beers.

Types of Brewery Fittings Used in Craft Beer Production

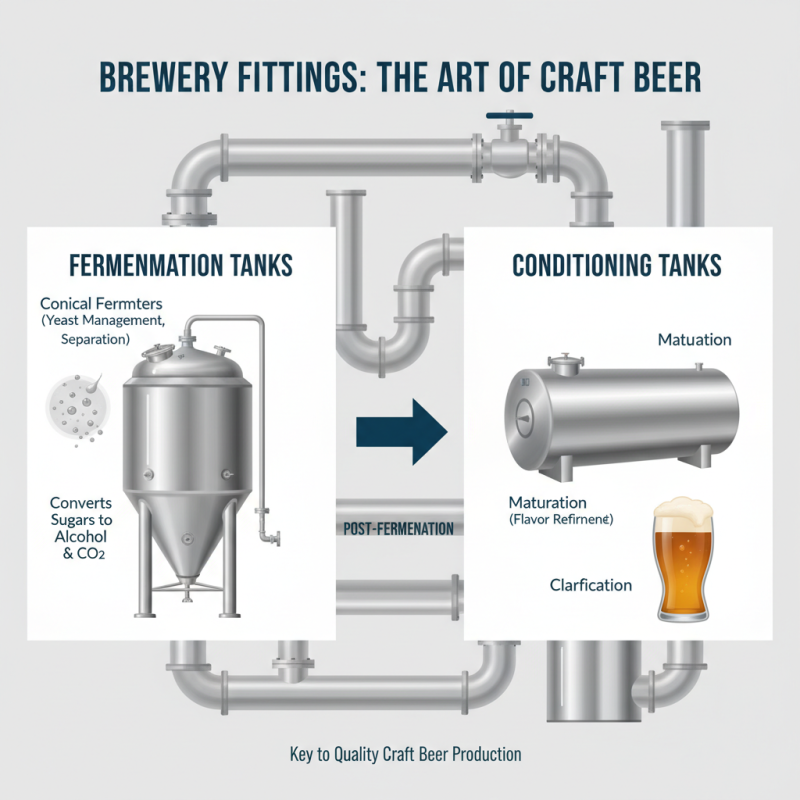

Brewery fittings play a crucial role in the production of craft beer, encompassing a variety of components that facilitate the brewing process. Among the essential fittings, fermentation tanks are vital, allowing yeast to convert sugars into alcohol and carbon dioxide. The selection of fermentation tanks varies, including options like conical fermenters, which can enhance yeast management and facilitate the separation of yeast from the beer after fermentation. Additionally, conditioning tanks are used for maturing the beer, which further refines its flavors.

Another important category of brewery fittings includes transfer lines and valves. These components are designed to move beer and other liquids safely between equipment without risking contamination. High-quality fittings ensure that the beer maintains its intended flavor profile throughout the brewing process. Furthermore, fittings such as pumps and heat exchangers are essential for controlling the temperature during brewing and cooling, ensuring optimal yeast activity and product consistency. Each type of fitting is specifically engineered to meet the demands of craft beer production, allowing brewers to focus on their creativity and quality.

The Role of Brewery Fittings in the Brewing Process

Brewery fittings are essential components in the brewing process, providing the necessary infrastructure for efficient beer production. These fittings encompass a variety of items, including valves, hoses, connectors, and couplings, designed to facilitate the flow of ingredients and the movement of beer throughout the brewing system. Their primary role is to ensure that the brewing process operates smoothly, allowing brewers to maintain quality and consistency in their craft beer.

In the brewing process, precise control over temperature, pressure, and flow is crucial. Brewery fittings enable this control by connecting different parts of the system, such as mash tuns, fermentation vessels, and filtration equipment. High-quality fittings can prevent leaks and contamination, which could otherwise spoil entire batches of beer. Additionally, they help brewers manage the transfer of ingredients and the final product, optimizing the brewing workflow and reducing downtime. By investing in reliable brewery fittings, craft brewers can significantly enhance their production capabilities, ensuring that they deliver exceptional beer to their customers.

Understanding Brewery Fittings and Their Impact on Craft Beer Production

Brewery fittings play a crucial role in craft beer production, impacting costs and efficiency across various areas such as fermentation, transport, and cleaning. The bar chart above illustrates the estimated costs associated with different types of brewery fittings necessary for optimal brewing practices.

Importance of Quality Brewery Fittings for Craft Breweries

Quality brewery fittings play a pivotal role in the production of craft beer, influencing not only the brewing process itself but also the overall efficiency and safety of a brewery. According to recent industry reports, nearly 60% of craft breweries cite equipment reliability as a critical factor in their operations. Components such as valves, fittings, and hoses need to withstand high temperatures and pressures while maintaining sanitary conditions to ensure the beer produced is of the highest quality. Subpar fittings can lead to leaks, contamination, and inefficient brewing processes, which can dramatically affect flavor profiles and overall yields.

Investing in high-quality brewery fittings can yield significant returns for craft breweries. For instance, the Brewers Association indicates that breweries using premium fittings report a 20% increase in production efficiency on average. This is partly due to reduced downtime caused by equipment failures, illustrating the tangible benefits associated with reliable fittings. Furthermore, proper fittings can enhance sanitation practices, reducing the risk of microbial contamination, which is crucial for maintaining the integrity of craft beer.

Tip: Regularly inspect and maintain all brewery fittings to identify any signs of wear or damage. This proactive approach can help prevent costly downtime and ensure consistent production quality. Additionally, consider consulting with industry specialists when selecting fittings to ensure they meet the specific needs of your brewing operations.

Maintenance and Care for Brewery Fittings in Brewing Facilities

Maintenance and care for brewery fittings are crucial in ensuring the smooth operation of brewing facilities. Precise cleaning and regular inspections of fittings like valves, pipes, and connectors help maintain hygiene standards and prevent contamination. These components, which play a vital role in the fermentation and transfer processes, should be regularly sanitized to ensure that no residual flavors or unwanted microorganisms affect the quality of the beer. Establishing a routine maintenance schedule can greatly reduce the risk of equipment failure and downtime, benefiting production efficiency.

In addition to cleaning, it is essential to check for signs of wear and tear in brewery fittings. Over time, frequent use can lead to the degradation of materials, affecting both the performance and safety of the fittings. Inspecting for leaks, corrosion, or any signs of damage ensures that any issues are addressed promptly, thereby preventing costly repairs or replacements. Additionally, maintaining proper temperatures and pressure levels within the system can prolong the lifespan of fittings and enhance the overall quality of the craft beer produced. By prioritizing these maintenance practices, brewing facilities can ensure optimal functionality and consistency in their beer production processes.

Related Posts

-

Essential Brewery Fittings Every Craft Brewer Must Have for Optimal Production

-

Essential Tips for Choosing the Right Brewery Fittings for Your Brewing Setup

-

Exploring Innovative Applications of Tubing Fittings for Modern Plumbing Solutions

-

10 Best Water Valves for Optimal Flow Control in 2023

-

How to Choose the Right Fittings and Valves for Your Industrial Needs

-

Top Strategies for Enhancing Performance with Fittings Valves