The 5 Best Sanitary Ball Valves for Optimal Performance in Your System?

In the world of fluid management, choosing the right components is critical. Among these, sanitary ball valves stand out for their reliability and performance. These valves play a vital role in various systems, especially in food and pharmaceutical industries. Their design ensures minimal product loss and easy maintenance.

However, not all sanitary ball valves are created equal. Performance can vary widely based on material and construction quality. For instance, some materials might corrode or degrade over time. This can lead to unexpected failures. It’s essential to invest time in research to identify the best options for your specific needs.

In this guide, we will explore the five best sanitary ball valves available today. Each selection is based on performance, durability, and user feedback. Finding the right valve for your system can significantly enhance efficiency. There might be areas to improve in understanding product specifications fully. Users often overlook crucial details, only to face issues later. Let’s dive into the options that promise optimal performance.

Overview of Sanitary Ball Valves and Their Importance in Systems

Sanitary ball valves play a crucial role in various systems, particularly in industries requiring strict hygienic conditions. Their design allows for smooth operation and easy cleaning, which is essential in processing applications. These valves help maintain the integrity of the system, preventing contamination and ensuring product quality. The materials used are often corrosion-resistant, adding durability to the equipment.

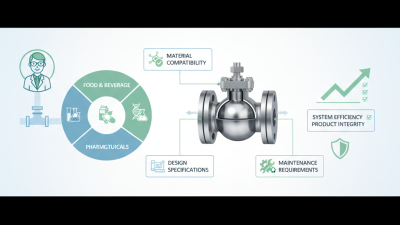

When selecting sanitary ball valves, it is important to consider the specific requirements of your system. Not all valves perform equally under different pressures and temperatures. A valve that works well in one application may not suit another. This mismatch can lead to operational issues and increased maintenance. Regular inspection is necessary to ensure the valves are functioning correctly.

It’s also worth noting that not every user fully understands how to properly install and maintain these valves. Misalignment and improper adjustments can lead to leaks and inefficiencies. Training staff to handle these components is often overlooked but crucial. A small oversight can have significant consequences in a complex system. Thus, taking the time to focus on these details is vital for optimal performance.

Key Features to Consider for Optimal Valve Performance

When selecting sanitary ball valves, several key features should guide your decision. Material is crucial. Stainless steel is a popular choice due to its durability and resistance to corrosion. Look for valves made from high-grade materials suitable for your specific application. This ensures longevity and safety.

Another important factor is the sealing mechanism. A good valve should have effective seals to prevent leaks. Consider valves with EPDM or PTFE seals for optimal performance. These materials maintain integrity under different temperatures.

Flow rate is also vital. Assess how the valve performs under varying pressure scenarios. A well-designed valve should maintain flow while minimizing pressure loss.

Finally, sanitation standards matter greatly. Ensure the valves meet industry regulations. This is essential for hygienic applications, especially in food or pharmaceutical sectors. Regular maintenance is often overlooked. Without it, even the best valves can fail. Simple inspections can help catch potential issues before they escalate. A little attention can make a difference.

Comparison of the Top 5 Sanitary Ball Valves in the Market

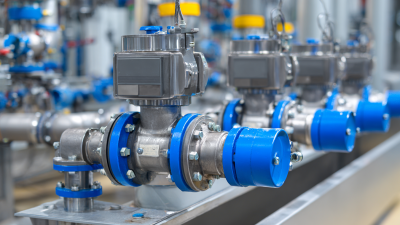

When comparing the top five sanitary ball valves on the market, several factors come into play. These valves play a critical role in fluid control systems. Their design ensures minimal leakage and maximum flow efficiency. Different materials and specifications cater to various applications, making the choice significant.

One key aspect to consider is the valve's construction. A durable body can withstand harsh conditions, while smooth internal surfaces reduce turbulence. Additionally, valve size impacts flow rate. Choosing the right size can optimize performance within your system.

Tips: Always check compatibility with your existing system. Look for user reviews that highlight long-term performance. Test several models if possible. Don't overlook installation ease; a complex setup can lead to mistakes. Remember, even the best valves can fail if misused or improperly installed. Maintain a focus on quality to ensure reliable operation.

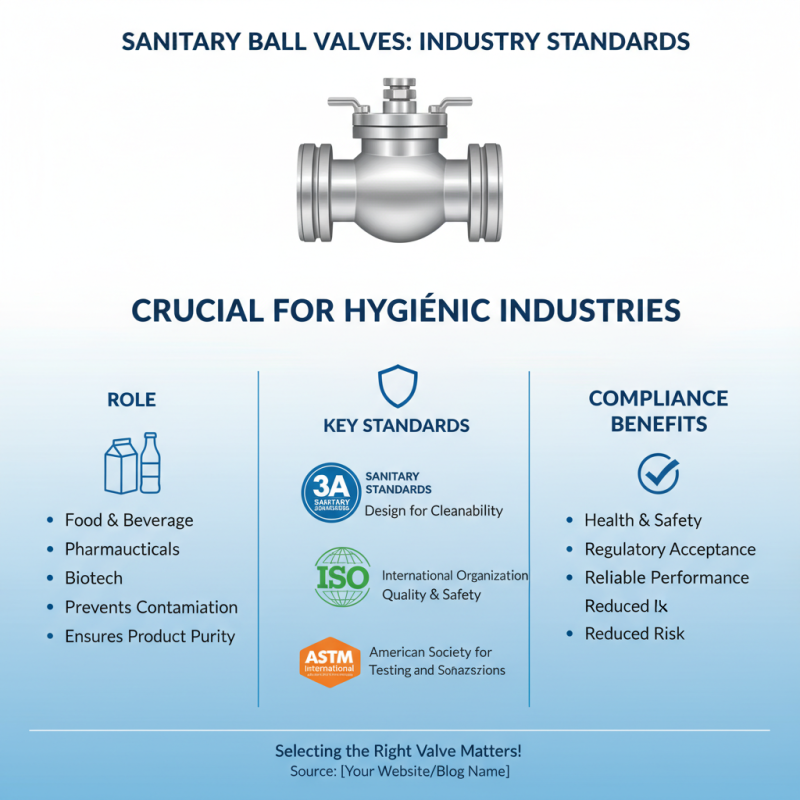

Industry Standards and Certifications for Sanitary Ball Valves

Sanitary ball valves play a crucial role in various industries, especially in food and beverage processing. Understanding industry standards is essential when selecting these components. Standards like ASTM, ISO, and 3A govern the manufacturing and quality of sanitary ball valves. Compliance ensures that products meet health and safety regulations.

The certifications these valves must attain often relate to material quality and hygiene. For instance, valves should be made from stainless steel to resist corrosion and contamination. Surface finish is also critical, with a smoother finish reducing the risk of bacteria harboring. However, not every valve adheres to these standards consistently. It's important to verify certifications before integration.

Quality control in production can vary. Some manufacturers may cut corners, jeopardizing performance. Regular audits and checks are vital. They can expose inconsistencies that lead to failures. Users need to remain vigilant in their selection process to ensure optimal performance in their systems.

Maintenance Practices to Ensure Long-lasting Valve Efficiency

Maintaining sanitary ball valves is crucial for optimal system performance. Regular inspection is necessary. Look for signs of wear or damage. Check seals and gaskets for leaks. Clean valves to remove any buildup. Neglecting these steps can lead to reduced efficiency.

Lubrication plays a vital role, too. Use appropriate lubricants for the specific environment. Avoid over-lubrication; it can attract dust and debris. Sometimes, valves may not perform as expected due to improper maintenance practices. Keeping a detailed log of service activities can provide insights over time.

Don’t forget to train staff on valve care. Knowledge of maintenance routines can improve valve lifespan. However, human error is always a risk. Mistakes happen even with the best intentions. Regular audits can help identify and correct these issues promptly.

Related Posts

-

2025 Guide: How to Choose the Right Sanitary Ball Valves for Your System

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

How to Choose the Right Sanitary Ball Valves for Your Applications

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries