Top 10 Best Pump Valves for Optimal Performance in Industrial Applications

In the realm of industrial applications, the significance of selecting the right pump valves cannot be overstated. According to a recent report by the Industrial Valves Association, the global market for pump valves is projected to reach $12 billion by 2025, driven by the increasing demand for efficient fluid control systems across various sectors such as oil and gas, chemicals, and water treatment. This growth underscores the necessity for industries to adopt the best technology and components to enhance operational efficiency and mitigate risks related to fluid handling.

Expert insights on this subject highlight the critical role that pump valves play in ensuring optimal performance. Dr. Emily Carter, a renowned authority in fluid dynamics, emphasizes, "The selection of pump valves can significantly influence not only the efficiency of fluid transfer processes but also the safety and reliability of industrial operations." Her perspective brings to light the intricate connection between valve design and industrial efficiency, making it imperative for engineers and procurement professionals to stay informed about the latest advancements in pump valve technology.

As we delve into the top 10 best pump valves for optimal performance in industrial applications, it is essential to consider both performance metrics and technological innovations that can lead to measurable improvements in production and cost-effectiveness. By carefully evaluating these components, industries can harness the full potential of pump valves and ensure seamless operations.

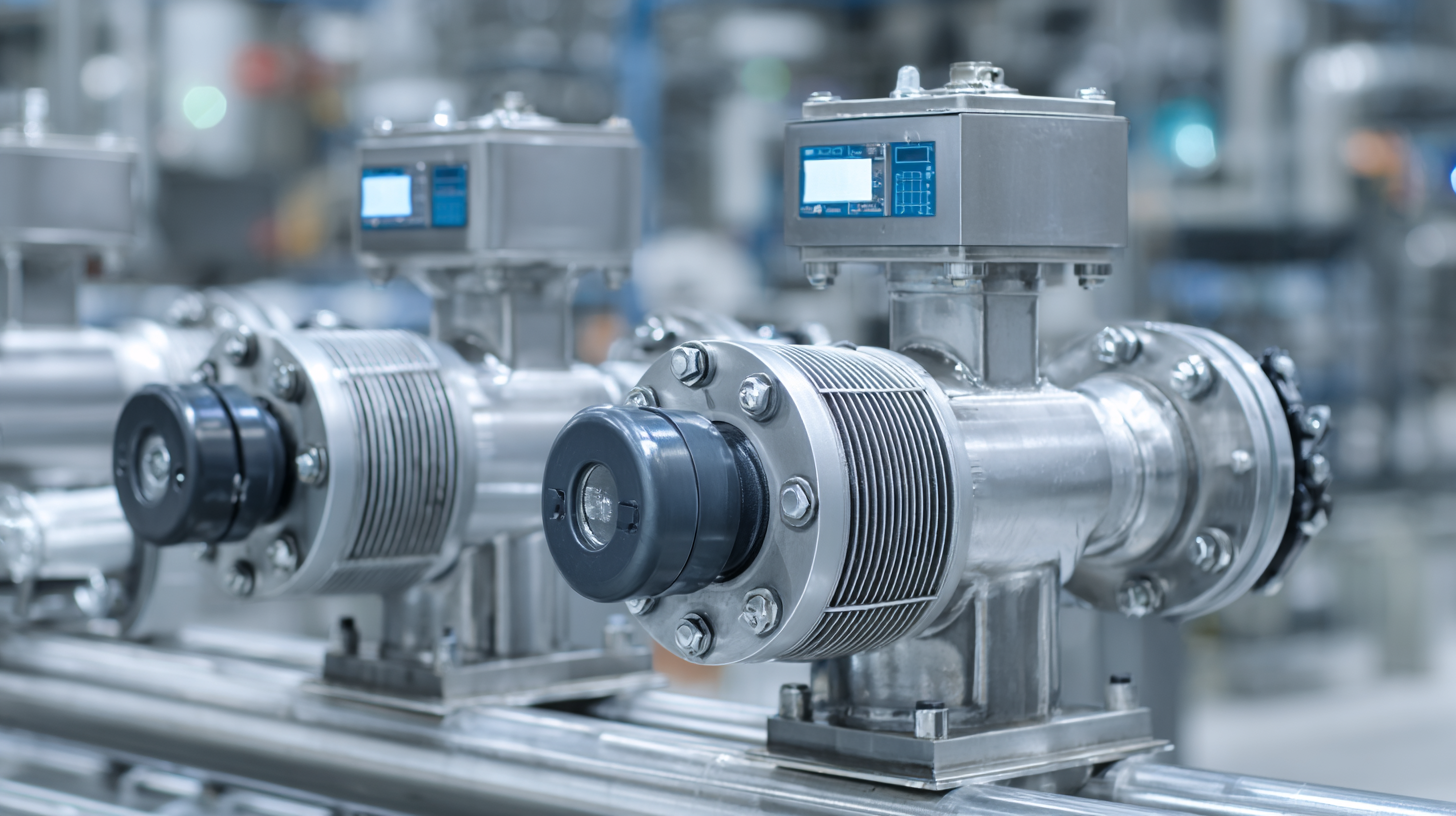

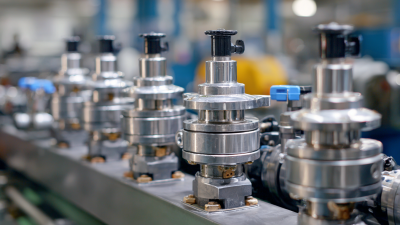

Top 5 Pump Valves: Revolutionizing Fluid Control in Industrial Settings

In the realm of industrial applications, the selection of the right pump valves is critical for achieving optimal fluid control. The top five pump valves currently revolutionizing fluid management in various settings highlight innovative designs and advanced materials that enhance performance and reliability. These valves not only improve efficiency but also reduce operational costs by minimizing leakage and maintenance requirements.

One standout option is the diaphragm pump valve, known for its ability to handle corrosive fluids without compromising integrity. Its design offers superior sealing capabilities, which prevents backflow and ensures precise control. Similarly, ball valves have gained popularity due to their robust construction and ease of operation, making them ideal for high-pressure applications. Additionally, butterfly valves provide a lightweight solution that allows for rapid opening and closing, catering to industries where speed is essential. Collectively, these advanced pump valves are setting new standards in fluid control, enabling industries to operate more effectively and sustainably.

Key Performance Metrics: Flow Rate and Pressure Handling for Optimal Efficiency

In industrial applications, the performance of pump valves is crucial for achieving optimal efficiency. Two key performance metrics that significantly influence the effectiveness of pump valves are flow rate and pressure handling. Flow rate, which quantifies the volume of fluid that can pass through the valve in a specific time frame, directly affects production capabilities. Selecting valves with appropriate flow rates ensures that operations maintain desired throughput levels, minimizing bottlenecks and enhancing productivity.

Equally important is pressure handling, which refers to a valve's ability to withstand and operate under varying pressure conditions without failure. Industrial environments often subject valves to high pressures, making it essential to choose models engineered for durability and resilience. A valve that can handle extreme pressures not only prolongs service life but also safeguards against leaks and failure, which can lead to costly downtime. When selecting the best pump valves, striking a balance between flow rate and pressure handling will ultimately determine the efficiency and reliability of industrial processes.

Material Selection: Analyzing Corrosion Resistance in Pump Valve Applications

In industrial applications, the selection of pump valve materials is critical for ensuring optimal performance and longevity. Corrosion resistance is a primary concern, as valves are often exposed to aggressive environments that can lead to significant wear and degradation. According to a report by the Materials Research Society, approximately 30% of all industrial maintenance costs stem from corrosion-related issues, underscoring the importance of selecting the right materials.

Stainless steel, particularly grades 304 and 316, are commonly used for their impressive resistance to a wide range of corrosive chemicals. However, for more extreme environments, such as those involving chloride ions, super duplex stainless steels or even specialized alloys like Hastelloy may be necessary. A study published in the Journal of Industrial Chemistry highlighted that the use of high-performance materials can reduce valve degradation rates by up to 70%, significantly extending service life and reducing replacement costs. By carefully analyzing the corrosion resistance of materials, industries can improve both reliability and efficiency in their pumping systems.

Maintenance and Durability: Extending the Lifecycle of Industrial Pump Valves

When it comes to industrial pump valves, maintenance and durability are crucial for extending their lifecycle and ensuring optimal performance. Regular inspections and timely servicing can identify potential issues before they escalate, reducing unexpected downtime. It’s important to clean the valves regularly to prevent build-up of debris that can impair functionality. Additionally, replacing seals and gaskets at the first sign of wear can significantly enhance the longevity of your valves.

Tip: Implement a routine maintenance schedule that includes checking for leaks, monitoring performance, and cleaning components as necessary. This proactive approach will help you avoid costly repairs and replacements down the line.

Another key aspect to consider is the material composition of your pump valves. Choosing the right materials that can withstand your specific operating conditions—such as temperature, pressure, and the type of fluids being conveyed—can dramatically improve durability. For instance, stainless steel valves can resist rust and corrosion, making them an excellent choice for harsh environments.

Tip: Consult with your supplier for recommendations on materials that best suit your industrial application, ensuring that you select components designed to last in demanding conditions.

Energy Efficiency: Impact of Pump Valve Design on Operational Costs in Industries

The design of pump valves plays a crucial role in enhancing energy efficiency within industrial applications. Properly designed valves can minimize pressure drops and regulate flow effectively, leading to significant reductions in energy consumption. When a valve allows fluid to flow smoothly with minimal resistance, it not only conserves energy but also lowers operational costs over time. Industries often overlook these components, yet they have a direct impact on overall system performance and energy bills.

Moreover, the choice of materials and engineering specifications in pump valve design can further optimize operations. For instance, advanced materials that resist wear and corrosion can prolong the lifespan of the valve, reducing maintenance costs and downtime. Additionally, intelligent valve designs equipped with automation features can adjust flow rates based on real-time demand, ensuring that energy is used only when necessary. This adaptability not only enhances performance but also aligns with modern sustainability goals in industrial processes. By investing in high-quality, efficient pump valves, organizations can achieve remarkable savings and bolster their commitment to operating sustainably.

Top 10 Best Pump Valves for Optimal Performance in Industrial Applications

| Pump Valve Type | Material | Max Pressure (psi) | Temperature Range (°F) | Energy Efficiency (%) | Operational Cost Savings ($/year) |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | 150 | -20 to 300 | 90 | 2000 |

| Gate Valve | Cast Iron | 250 | 0 to 250 | 85 | 1500 |

| Globe Valve | Brass | 100 | -10 to 200 | 80 | 1200 |

| Check Valve | PVC | 75 | -10 to 140 | 75 | 800 |

| Pressure Relief Valve | Aluminum | 150 | -20 to 260 | 88 | 1700 |

| Butterfly Valve | Polymer | 200 | -40 to 150 | 92 | 2200 |

| Pinch Valve | Rubber | 50 | -10 to 180 | 78 | 900 |

| Automatic Control Valve | Stainless Steel | 300 | -20 to 400 | 95 | 2500 |

| Diaphragm Valve | EPDM Rubber | 150 | -10 to 260 | 85 | 1300 |

| Solenoid Valve | Brass | 250 | -20 to 200 | 90 | 2100 |

Related Posts

-

How to Select the Right Pump Valves for Your Industrial Applications

-

7 Essential Tips for Choosing the Right Sanitary Fittings for Your Project

-

Essential Guide to Choosing the Right Valve Fittings for Optimal Performance

-

Unlocking Global Opportunities for Weld Fittings at the 138th Canton Fair 2025 in China

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs

-

The Ultimate Guide to Choosing the Right Ball Valves for Your Plumbing Projects