10 Best Plug Valves: Unlocking 20% More Efficiency in Your Piping Systems

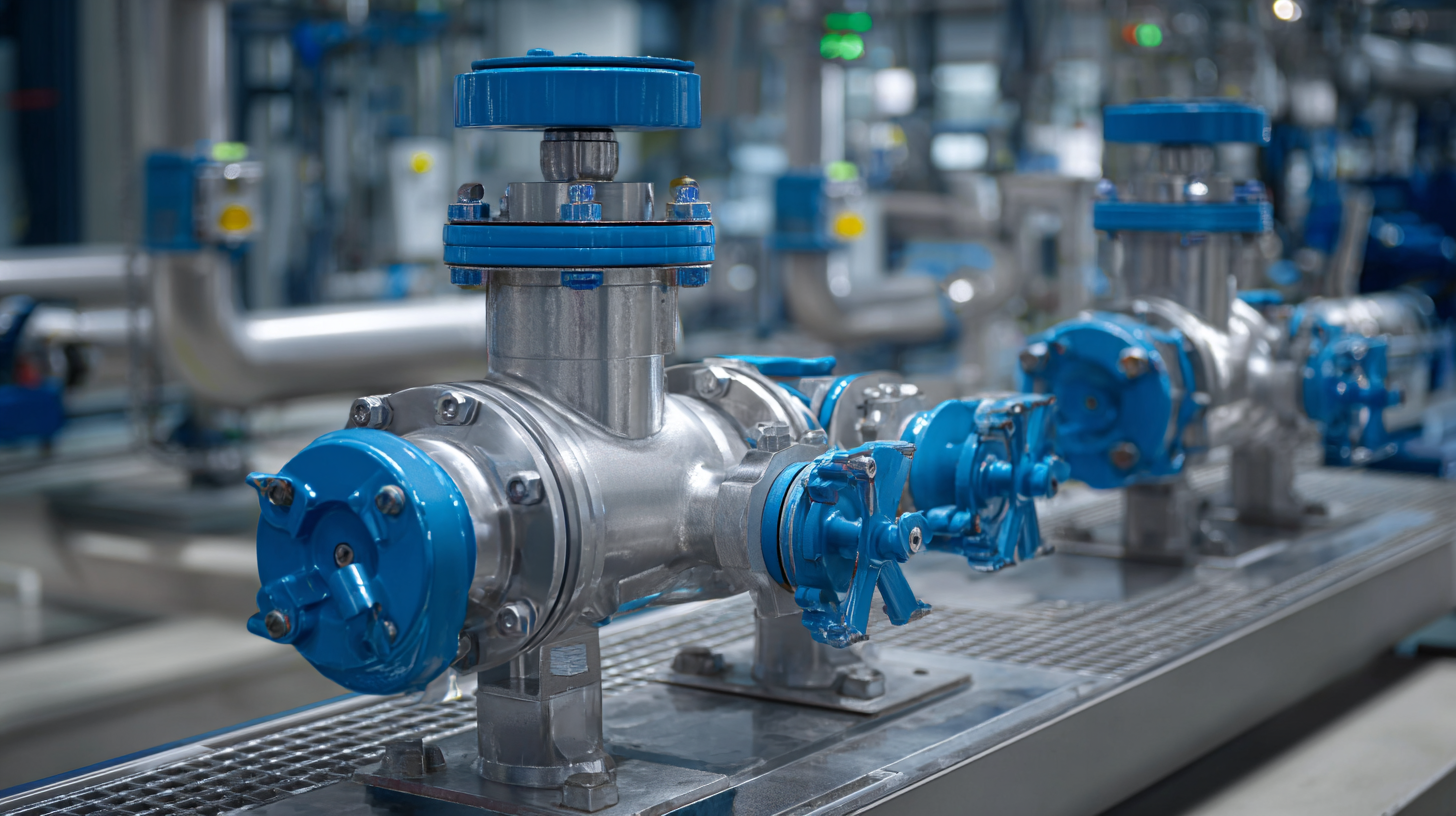

In the realm of industrial piping systems, the efficiency and reliability of flow control components play a crucial role in operational success. Among these components, plug valves have emerged as a preferred choice due to their ability to provide quick shut-off capabilities and minimize pressure drop. Recent industry reports indicate that using advanced plug valves can enhance system efficiency by up to 20%, thereby contributing to significant operational cost savings and improved process performance.

As industries increasingly prioritize sustainability and resource optimization, understanding the intricacies of plug valves becomes essential for engineers and maintenance professionals alike. This article will explore the ten best plug valves available in the market, delving into their features, applications, and the tangible benefits they can bring to your piping systems, ultimately guiding you to make informed decisions for enhanced efficiency.

Exploring the Advantages of Plug Valves in Modern Piping Systems

Plug valves are increasingly becoming a preferred choice in modern piping systems due to their unique advantages. Unlike other valve types, plug valves offer a straightforward design that facilitates efficient flow control. The tapered or cylindrical plugs can be easily rotated within a valve body, allowing for quick opening and closing. This ease of operation significantly minimizes the amount of time and effort required for maintenance and adjustments, making them ideal for high-demand industrial applications.

Moreover, plug valves are known for their ability to provide a tight seal, ensuring minimal leakage when closed. This characteristic not only enhances the efficiency of the system by maintaining optimal pressure but also contributes to safety by reducing potential hazards associated with leaks. Additionally, they are suitable for a wide range of fluids—including corrosive substances—thanks to various material options available. As industries increasingly prioritize efficiency and reliability in their piping systems, the adoption of plug valves can lead to an impressive boost in overall performance while also unlocking the potential for

significant energy savings.

Key Features to Consider When Choosing the Best Plug Valve for Your Needs

When selecting the best plug valve for your piping systems, understanding the key features is essential to unlocking greater efficiency. First and foremost, consider the body material of the valve. Common choices include bronze, stainless steel, and plastic, each offering distinct advantages depending on the medium being transported and the operating environment. For instance, stainless steel valves are preferred for high temperatures and corrosive applications, while plastic valves are lightweight and resist chemical degradation.

Another critical factor is the valve's size and type of end connection. Ensuring compatibility with existing piping is crucial for seamless installation and optimal performance. Additionally, the valve's sealing mechanism plays a vital role in preventing leaks and maintaining pressure. Look for models featuring robust seals made of high-quality elastomers or advanced materials that can withstand varying pressures and temperatures. Finally, consider the ease of maintenance, as some plug valves are designed for quick disassembly without special tools, which can significantly reduce downtime during repairs or replacements. By focusing on these key features, you can enhance the efficiency and reliability of your piping systems.

Efficiency Comparison of Different Plug Valves

Comparative Analysis: Plug Valves vs. Other Valve Types in Efficiency

When evaluating efficiency in piping systems, the choice of valve can significantly impact performance. This comparative analysis delves into the reasons why plug valves stand out against other types like globe or ball valves. Plug valves offer a straightforward design, allowing for quick and unobstructed flow, which can translate to a notable increase in efficiency—up to 20% in some systems. Their ability to provide tight sealing and minimal pressure drop makes them ideal for a variety of industrial applications.

Moreover, the global industrial valves market is anticipated to see substantial growth in the coming years, from USD 86.67 billion in 2025 to USD 131.6 billion by 2033. This growth reflects a rising demand for efficient fluid control solutions, including hydrogen valves technology, which promises to enhance performance in specific sectors. As manufacturers innovate and develop more advanced valve systems, the choice between plug valves and others becomes increasingly significant, as organizations seek to improve operational efficiency and reduce costs across their piping infrastructure.

Installation and Maintenance Best Practices for Optimal Performance

When it comes to achieving optimal performance from your plug valves, installation and maintenance are paramount. Proper installation begins with ensuring that the valve is compatible with your piping system and that all dimensions align correctly. It's critical to clean the pipe ends to remove any debris, as this can impede the sealing surfaces and lead to leaks. Additionally, consider using thread sealants that are compatible with the valve material and the fluid being transported. Ensuring that the valve is installed in the correct orientation—typically with the handle positioned for easy operation—will enhance accessibility and functionality.

Regular maintenance is essential to ensure the longevity and efficiency of your plug valves. Routine inspections should be conducted to check for wear and tear or signs of corrosion. Lubricating the valve periodically will help prevent sticking and maintain smooth operation. It's also vital to exercise the valve regularly, as this can prevent seating issues that could arise from long periods of inactivity. By adhering to these best practices, you can unlock significant efficiency gains in your piping systems, ensuring they operate at peak performance with reduced downtime.

10 Best Plug Valves: Unlocking 20% More Efficiency in Your Piping Systems - Installation and Maintenance Best Practices for Optimal Performance

| Valve Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Applications | Installation Tips | Maintenance Frequency |

|---|---|---|---|---|---|---|

| Full Port | Stainless Steel | 150 | -20 to 400 | Water, Gas | Ensure proper alignment and sealing | Annually |

| Compact | Carbon Steel | 300 | -40 to 300 | Oil, Chemical | Use proper torque values | Semi-Annual |

| Metal Seated | Alloy | 600 | -50 to 500 | Steam, High Pressure | Align according to standards | Quarterly |

| Plastic | PVC | 150 | -10 to 140 | Acids, Corrosives | Chemical resistant lubricants | Annually |

| High Performance | Bronze | 250 | -20 to 350 | Water Treatment | Check for wear and tear | Bi-Annual |

Real-World Case Studies Demonstrating Efficiency Improvements with Plug Valves

Plug valves are gaining recognition for their significant impact on the efficiency of piping systems. In various real-world applications, industries have reported efficiency improvements of up to 20% after switching to plug valves. For instance, a chemical manufacturing plant replaced traditional gate valves with plug valves and, as a result, experienced not only enhanced flow rates but also reduced energy consumption. This upgrade allowed for smoother operations and increased throughput, demonstrating how a simple change in valve design can translate into considerable operational gains.

Another compelling case study comes from the wastewater management sector, where a municipal treatment facility implemented plug valves to optimize their sludge handling processes. The facility noticed a dramatic decrease in operational downtime due to the valves' reliable performance and ease of maintenance. The plant administrators highlighted that the plug valves' streamlined design facilitated quicker adjustments and repairs, allowing for more consistent treatment cycles and improved overall system performance. These examples underline the tangible benefits of plug valves in driving efficiency and reliability across various industries.

Related Posts

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs

-

7 Essential Tips for Choosing the Right Sanitary Fittings for Your Project

-

How to Choose the Right Water Valves for Your Global Supply Needs

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

Understanding the Types of Tubing Fittings for Optimal Performance

-

Understanding the Role of Diaphragm Valves in Modern Industrial Applications