Top 10 Benefits of Using Sanitary Tubing in Industries?

In many industries, the importance of sanitary tubing cannot be overstated. This specialized tubing is designed for the safe transport of fluids in environments where hygiene is critical. Commonly used in food, beverage, and pharmaceutical sectors, it ensures the integrity of sensitive products.

Sanitary tubing offers numerous benefits that enhance operational efficiency and safety. Its smooth surface minimizes the risk of bacterial buildup. Moreover, it is resistant to various chemicals, prolonging its lifespan. Industries rely on sanitary tubing for consistent performance and compliance with health standards.

However, it is essential to recognize that not all tubing is created equal. Companies must invest in high-quality materials to ensure maximum benefits. Ultimately, the decision to use sanitary tubing can significantly impact product quality and safety. This choice warrants careful consideration and reflection on best practices.

Overview of Sanitary Tubing and Its Applications in Industries

Sanitary tubing is essential in various industries. It is primarily used in food, beverage, pharmaceutical, and biotechnology sectors. This type of tubing ensures that products remain uncontaminated during processing and transport. According to a recent report by MarketsandMarkets, the sanitary tubing market is projected to reach $2.8 billion by 2025, growing at a CAGR of 5.3%. This indicates a rising demand driven by stricter health regulations.

The applications of sanitary tubing are vast. In the food industry, it is used to transfer liquids like milk and juices. In pharmaceuticals, it serves for transporting medicines and ensuring purity. It helps meet the FDA standards, which is crucial for compliance. Incompatible materials can lead to failures in safety and quality. Additionally, the design of sanitary tubing can influence cleaning efficiency. A poorly designed system may harbor bacteria.

In several cases, industries underestimate the importance of regular inspections. Failure to detect wear and tear can result in costly downtimes. With rising industry standards, ongoing training and education about proper maintenance procedures are necessary. Data from the European Hygienic Engineering & Design Group suggests that up to 30% of product recalls could be linked to equipment failures. Regular assessments can mitigate these risks, ensuring safe operation across all applications.

Enhanced Hygiene Standards: Why Sanitary Tubing is Essential

Sanitary tubing plays a vital role in maintaining high hygiene standards across various industries. It is primarily designed to prevent contamination, which can occur in processes like food and beverage production or pharmaceuticals. The smooth interior surface of sanitary tubing is easy to clean. This means fewer bacteria can thrive, making it ideal for sensitive applications.

Hygiene is not just a guideline; it’s a necessity. When sanitary tubing is used, companies are more likely to comply with health regulations. They can reduce the risk of product recalls, which can be expensive and damaging to brand reputation. However, not all facilities prioritize regular inspections of these systems. This may lead to unnoticed wear or improper connections, presenting significant health risks.

While the benefits are clear, it’s easy to overlook regular maintenance. It’s crucial to understand that tubing is just one part of a larger system. Routine audits and staff training on sanitary practices can enhance the overall hygiene of an operation. Investing in sanitary tubing is a step forward, but sustaining those standards requires continuous effort and vigilance.

Top 10 Benefits of Using Sanitary Tubing in Industries

This bar chart illustrates the top benefits of using sanitary tubing across various industries, highlighting the importance of enhanced hygiene standards.

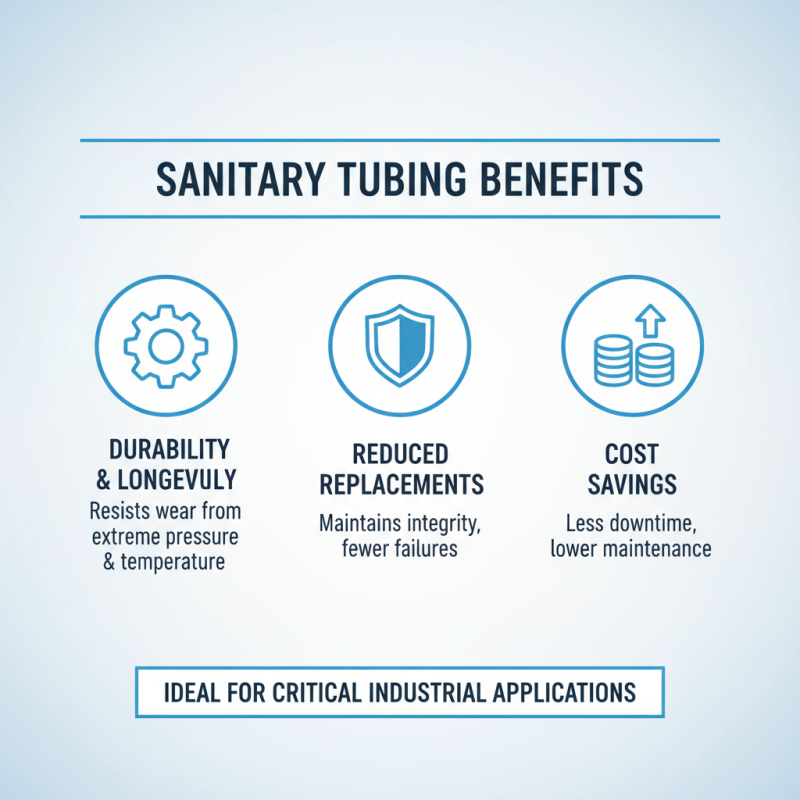

Durability and Longevity: The Benefits of High-Quality Materials

High-quality sanitary tubing offers remarkable durability and longevity, crucial in many industries. It is designed to withstand extreme conditions. For example, high pressures and temperatures can wear down standard tubing quickly. In contrast, sanitary tubing maintains its integrity longer. This reduces the need for frequent replacements, ultimately saving costs.

Materials used in sanitary tubing are carefully chosen for their resistance. Stainless steel, often used, is not only robust but also corrosion-resistant. This ensures that hygiene remains intact, essential in sectors like food and pharmaceuticals. Imagine a food processing plant that relies on clean, safe transport of liquids. Any compromise can lead to significant setbacks, including contamination.

However, it's important to note that not all tubing is created equally. Some may not meet industry standards, leading to potential risks. A thoughtful evaluation of material quality is key. Investing in high-quality sanitary tubing can present a challenge, but the benefits often outweigh initial concerns. Long-term reliability often brings peace of mind and operational efficiency.

Cost-Effectiveness: Long-Term Savings with Sanitary Tubing

Sanitary tubing is a crucial component in many industries, especially in food and beverage, pharmaceuticals, and cosmetics. One significant advantage is its cost-effectiveness. According to a report from the International Society for Pharmaceutical Engineering, businesses can reduce cleaning time by up to 30% by using high-quality sanitary tubing. This means lower labor costs and improved efficiency in production.

Over time, the initial investment in sanitary tubing pays off. The Tubing Manufacturer's Association notes that durability leads to fewer replacements and repairs. Tubing made from stainless steel, for example, lasts much longer than plastic alternatives. This reduces the frequency of purchasing new materials and lowers long-term expenses. However, companies must choose the right grade of tubing. Not all options may provide the same level of durability and cost savings.

Another point to consider is the maintenance. While sanitary tubing is designed for easy cleaning, improper use can lead to costly downtime. Some businesses may overlook recommended cleaning protocols, resulting in more frequent inspections and repairs. For instance, a report from the Food and Drug Administration indicates that 18% of recalls are due to contamination issues linked to outdated tubing practices. The potential savings are high, but only if companies commit to proper maintenance.

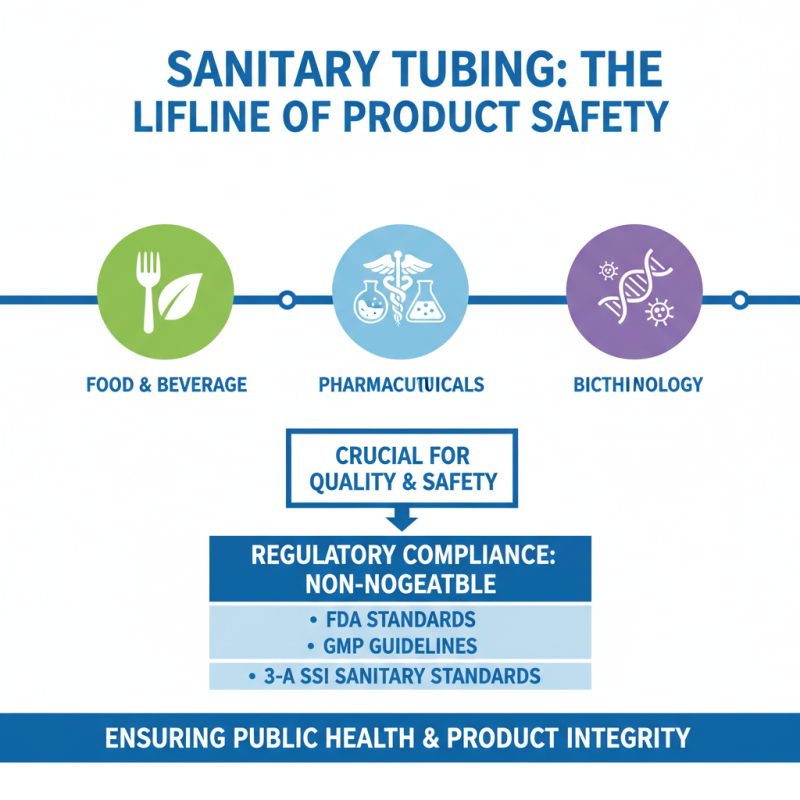

Compliance with Industry Regulations: Ensuring Safety and Quality

Sanitary tubing is a crucial component in many industries. It often serves as a lifeline for ensuring product safety and quality. Compliance with industry regulations is paramount. Many sectors, such as food and beverage, pharmaceuticals, and biotechnology, require strict adherence to safety standards.

Using sanitary tubing helps meet these rigorous demands. It reduces contamination risks, which is vital for products affecting public health. Smooth surfaces on these tubes prevent bacteria growth. This design element promotes easier cleaning, addressing a key point in many compliance checks. However, not all organizations prioritize these features. Some may overlook maintenance or quality assurance, leading to potential safety issues.

Inadequate training of staff can also pose risks. Employees must understand the importance of using proper materials. It’s a shared responsibility to maintain industry standards. Inconsistent practices may undermine confidence in product safety. Organizations should continuously evaluate their processes and training programs. This reflection can lead to improved compliance and a safer workplace.

Related Posts

-

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing

-

The Ultimate Guide to Choosing the Best Sanitary Tubing for Your Business Needs

-

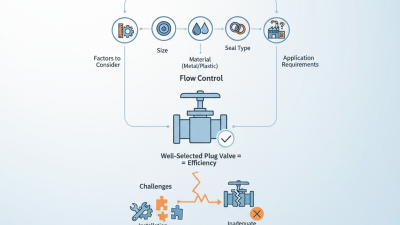

How to Choose Plug Valves for Your Industrial Applications?

-

How to Choose the Right Water Valves for Your Global Supply Needs

-

Why Sanitary Connectors Are Essential for Maintaining Hygiene in Food Production

-

Why Are Sanitary Connectors Essential for Food Safety?