Top 10 Benefits of Using Plug Valves in Industrial Applications?

Plug valves are essential components in industrial applications. They provide reliable flow control and isolation in various settings. According to a report from Market Research Future, the global plug valve market is expected to grow significantly, driven by increased demand from the oil and gas industry. Reports indicate that plug valves account for a substantial share of the total valve market, as they offer advantages like low-pressure drop and minimal turbulence.

These valves feature a cylindrical or tapered design that turns to open or close the flow. Their simple mechanism leads to cost savings in maintenance and operation. However, the effectiveness of plug valves is often influenced by factors like the medium being transported and installation locations. This necessitates careful consideration and effort from engineers and operators alike.

While plug valves excel in many situations, some limitations exist. Seal leakage can occur if not properly maintained, leading to inefficiencies. As industries adopt new technologies, continuous improvement in valve design is crucial. Balancing benefits with potential issues requires ongoing evaluation and adaptation by professionals in the field. The growing reliance on plug valves signifies their importance, but awareness of their shortcomings is key for optimal performance.

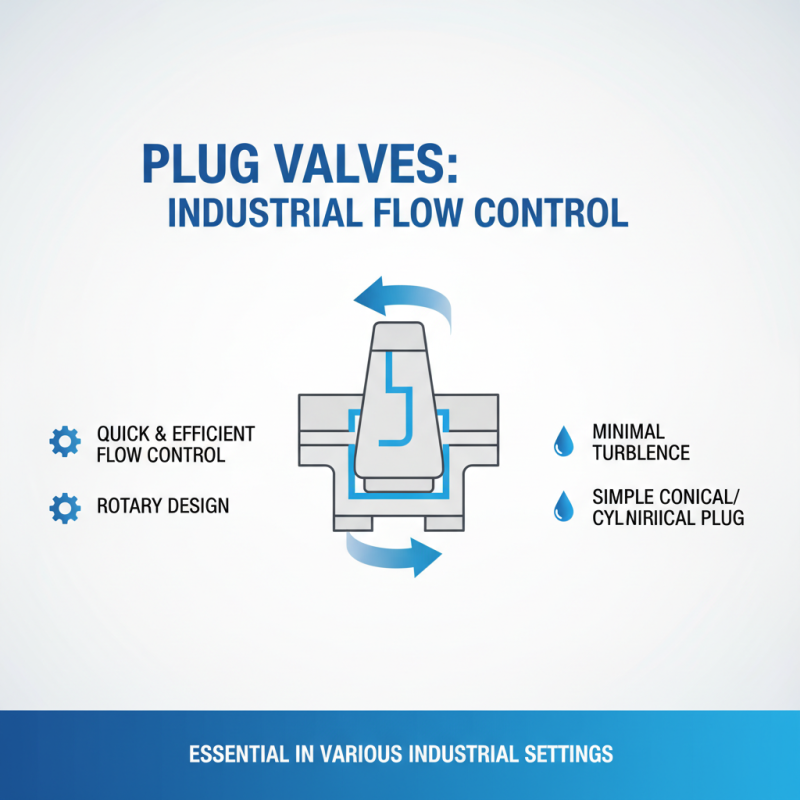

Key Features of Plug Valves in Industrial Settings

Plug valves are essential in various industrial settings due to their unique characteristics. They offer a quick and efficient method for controlling flow. These valves feature a rotary design, allowing for smooth operation. Their simple structure consists of a conical or cylindrical plug. This design minimizes turbulence, which is crucial in many processes.

Another notable feature is the tight seal provided by plug valves. This prevents leakage and ensures system integrity. They are often designed for high-pressure applications, making them suitable for challenging environments. Maintenance can pose some difficulties. Replacing worn components might require system downtime, which manufacturers often want to avoid.

Moreover, plug valves are compact, taking up less space than other types. This can be an advantage in facilities with limited room. However, one needs to consider the specific needs of the application. Choosing the right valve requires understanding fluid characteristics and operational demands. Manufacturers may sometimes overlook these details, leading to performance issues. Attention to these aspects can enhance operational effectiveness.

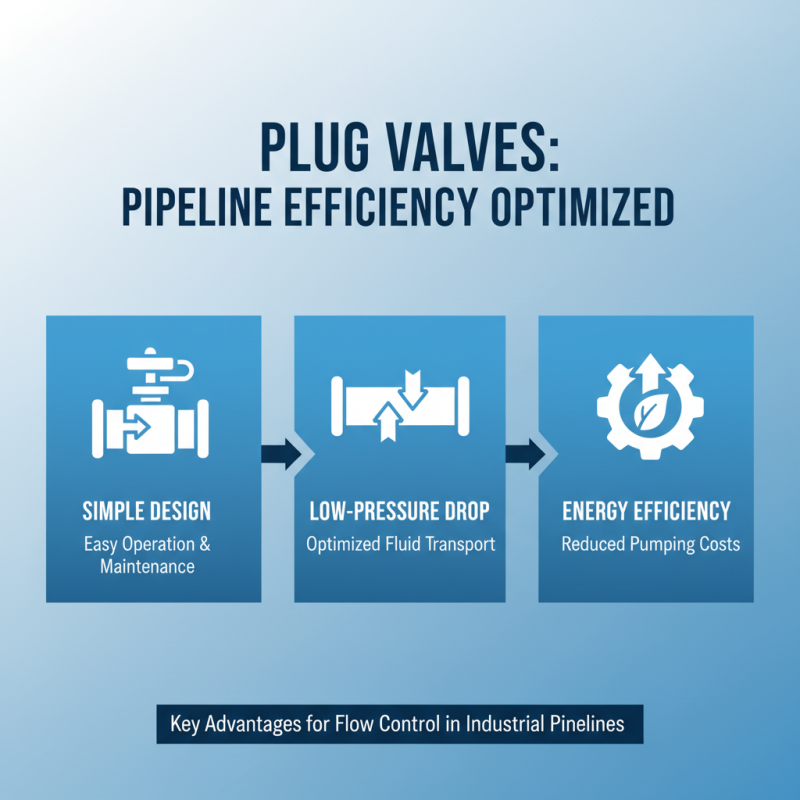

Benefits of Plug Valves for Flow Control in Pipelines

Plug valves offer significant advantages for flow control in pipelines. These valves are simple in design, making them easy to operate and maintain. They can efficiently manage flow in various industrial applications. According to industry reports, plug valves have a low-pressure drop, optimizing fluid transport. This leads to better energy efficiency in pipeline systems.

One key benefit is their ability to handle high temperatures and pressures. This makes them suitable for diverse environments. The versatility of plug valves means they can function well with liquids, gases, or slurries. However, their performance relies heavily on proper installation and regular maintenance. Neglecting these aspects can lead to failures and costly downtimes.

Tips: Ensure that the valve materials match the fluid characteristics. This prevents corrosion and leaks. Regular inspections are crucial to maintain efficiency. Tune-up schedules must be established. Even small wear and tear can lead to significant issues.

Plug valves also provide quick shut-off capabilities. This feature enhances safety in processes requiring immediate response to flow changes. However, be cautious with over-tightening during installation. It can damage the valve, leading to leaks. Understanding the operational environment and using these valves properly can yield great results.

Durability and Maintenance Advantages of Plug Valves

Plug valves are highly favored in industrial settings for their durability and low maintenance needs. According to industry reports, these valves can withstand harsh operating conditions, making them a reliable choice. Plug valves feature simple designs that reduce wear and tear over time. This simplicity leads to fewer components that could fail, which is a significant advantage in high-demand environments.

Regular maintenance for valve systems can be burdensome. However, plug valves generally require less frequent overhauls compared to other types of valves. Their sturdy construction can last for many years, often exceeding expectations in longevity. Some studies indicate that plug valves can operate effectively even in challenging media, like slurries or viscous fluids, without compromising performance.

Tip: Always inspect the sealing surfaces. A small imperfection can lead to leakage. Small adjustments in maintenance routines can have a big impact.

In addition, if repairs are needed, plug valves can be serviced easily without extensive disassembly. When considering industrial applications, it’s essential to weigh the benefits of a straightforward maintenance process against potential operation costs. Even a missed routine check can lead to unexpected complications, so being proactive is key.

Applications of Plug Valves in Different Industries

Plug valves play a significant role in diverse industrial sectors. Their design allows for quick opening and closing of the flow. In the oil and gas industry, plug valves are essential for controlling liquids and gases. They have a low pressure drop, making them efficient. According to a recent industry report, plug valves can help reduce energy costs by up to 30%. This efficiency is critical in processes that require tight control over fluid movement.

In the water treatment sector, these valves help manage flow rates effectively. Their ability to handle suspended solids makes them suitable for this application. Industries that face abrasive materials also benefit from plug valves. Their durable construction allows them to withstand harsh conditions. However, regular maintenance is key to ensuring longevity. Lagging behind in maintenance can lead to unexpected downtimes.

Tip: Always assess the specific needs of your application before selecting a valve. Some industries may require specialized materials. Understanding your operational requirements will optimize valve performance.

Plug valves find uses in other areas too, like pharmaceuticals and chemical processing. Their clean and simple design minimizes contamination risks. However, there may be limitations in high-pressure scenarios. It’s important to analyze these factors before decisions are made.

Top 10 Benefits of Using Plug Valves in Industrial Applications

| Benefit | Description | Industry Application |

|---|---|---|

| Reliable Operation | Plug valves provide a dependable sealing mechanism to prevent leakage. | Oil & Gas |

| Low Pressure Drop | The streamlined design minimizes pressure loss during fluid flow. | Chemical Processing |

| Simplicity of Design | Plug valves feature a simple design with fewer moving parts. | Water Treatment |

| Quick Operation | They allow for fast operation, enabling quick open and close actions. | Food & Beverage |

| Versatile Use | Plug valves can handle a variety of fluids and gases, including slurries. | Mineral Processing |

| Durability | Constructed from robust materials to withstand harsh conditions. | Power Generation |

| Ease of Maintenance | Maintenance is quick and straightforward without special tools. | Pharmaceuticals |

| Space Efficiency | Their compact design saves space, making them suitable for tight installations. | Marine |

| Cost-Effectiveness | Long lifespan and reduced maintenance costs translate to savings. | Construction |

| Excellent Flow Control | Enables precise control over the flow rate of fluids and gases. | HVAC |

Cost-Effectiveness of Plug Valves Over Time

In industrial applications, plug valves stand out for their cost-effectiveness over time. Research indicates that using plug valves can lead to a 20-30% reduction in maintenance costs over their lifespan. Their simple design allows for easy operation and fewer parts, making repairs straightforward. Companies can save money by reducing downtime and labor costs.

Additionally, plug valves often excel in preventing leaks. According to industry reports, they can achieve leakage rates as low as 0.1% under certain conditions. This means less product loss and lower environmental impact. Over years of operation, this can translate to significant savings. Industries heavily reliant on fluid management are seeing the benefits, but some still overlook this potential.

However, plug valves are not without drawbacks. Some may struggle with particulate matter, leading to potential clogging. This issue can increase maintenance needs in specific environments. Companies should assess their unique conditions to make an informed choice. Plug valves offer advantages, but each situation requires careful consideration.

Related Posts

-

10 Best Plug Valves: Unlocking 20% More Efficiency in Your Piping Systems

-

Top 10 Essential Brewery Fittings Every Brewer Should Consider

-

Understanding the Role of Diaphragm Valves in Modern Industrial Applications

-

The Future of Diaphragm Valves Set to Transform Fluid Control Technologies

-

6 Tips to Choose the Right Sanitary Connectors for Optimal Hygiene Compliance

-

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing