2026 Guide: How to Choose the Right Sanitary Ball Valves for Your Needs

Choosing the right sanitary ball valves is crucial for various applications in the food and pharmaceutical industries. These valves play a significant role in ensuring product safety and maintaining hygiene. With many options available, selecting the best one can seem overwhelming. Understanding your specific needs is essential.

When evaluating sanitary ball valves, consider factors like size, materials, and pressure ratings. Each detail impacts performance and durability. High-quality materials, such as stainless steel, are vital for preventing contamination. Regular maintenance is also important. It affects the longevity and efficiency of the valves.

Not every valve will meet your expectations. Some may not fit well in your system. Make sure to explore different manufacturers and product specifications. Seek expert advice if needed. This thorough approach will help you make informed decisions and ultimately enhance the safety of your processes.

Understanding Sanitary Ball Valves: Definition and Applications

Sanitary ball valves are crucial in various industries. They provide a reliable solution for controlling fluid flow in hygienic applications. These valves are designed to meet specific cleanliness standards. They're commonly used in food processing, pharmaceuticals, and biotechnology. Their smooth interior surfaces help prevent contamination. This feature is vital for maintaining product quality and safety.

Understanding the definition of sanitary ball valves is the first step. Unlike traditional valves, they have a spherical closure element that facilitates flow control. This design minimizes turbulence, ensuring a steady flow. Sanitary ball valves often come in different configurations, such as trunnion or floating styles. Each type serves distinct functions. Some might find it challenging to choose the right type for their application. This choice depends on pressure, temperature, and fluid characteristics.

Choosing the right sanitary ball valve requires careful consideration. Many overlook the importance of material selection. Valves made from stainless steel offer durability and resistance to corrosion. However, budget constraints can complicate decisions. Users may need to balance cost and performance. Knowing the specific needs of your application is crucial. It ensures the valve will perform as needed, preventing costly mistakes down the line.

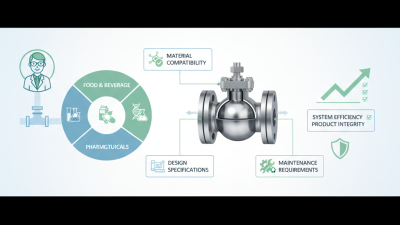

Key Factors in Selecting Sanitary Ball Valves for Your Process

Choosing the right sanitary ball valves can be challenging. There are various factors to consider based on your specific needs. One crucial aspect is the material. You should think about the substances the valves will handle.

Different materials react differently to various chemicals. For instance, stainless steel is popular for its durability and resistance.

Another key factor is the design of the valve. A three-piece design can offer easy maintenance and replacement. However, it may take more space than a two-piece valve. Space is often limited in production facilities.

The right design balances efficiency and maintenance ease. Consider your system's configuration carefully.

Finally, don’t overlook the size of the valve. A valve too small may restrict flow. A valve too large can lead to inefficiencies.

It's difficult to get this right sometimes. Reflecting on operational conditions is essential. The wrong choice can lead to downtime and increased costs. Adjusting expectations is part of the process.

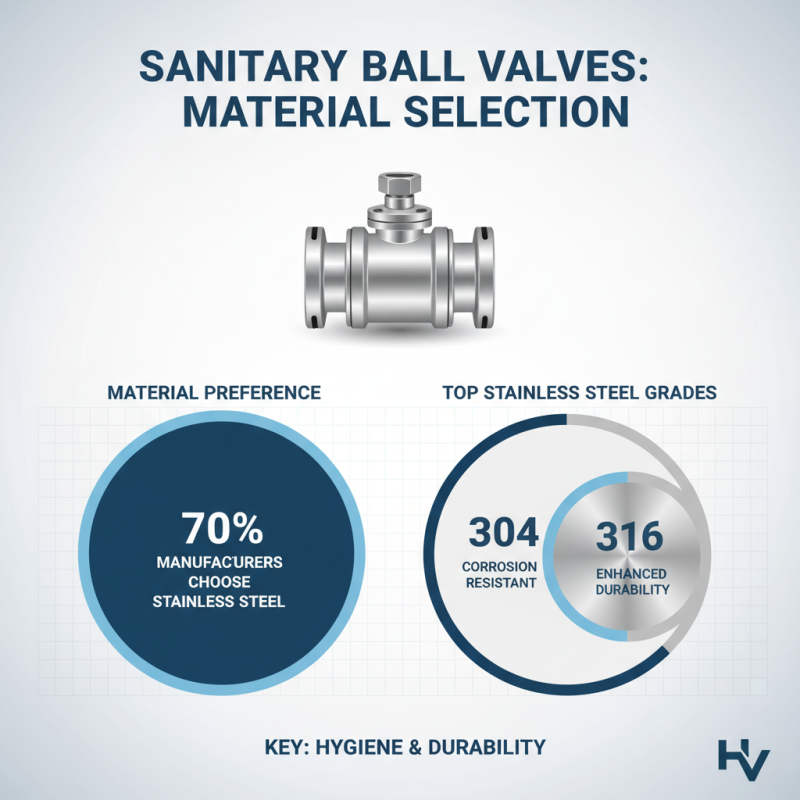

Material Considerations for Sanitary Ball Valves: What You Need to Know

Choosing the right material for sanitary ball valves is crucial. Various materials are available, each with specific properties. Stainless steel is a common choice for hygienic applications, offering excellent corrosion resistance. According to a recent industry report, 70% of manufacturers prefer 304 or 316 stainless steel for its durability.

Plastic options are also popular. They can be lighter and less expensive than metal alternatives. However, they might not withstand high temperatures or aggressive chemicals. The same report identifies that over 30% of facilities use plastic valves in low-pressure systems. It's essential to evaluate your specific needs carefully.

Don't overlook maintenance needs as well. Some materials require more upkeep than others. For example, while stainless steel is durable, it can show signs of wear over time. In contrast, plastic may degrade faster under harsh conditions. Balancing cost, performance, and longevity is vital for making effective material choices. Remember, choosing the wrong type could lead to expensive repairs.

The Role of Valve Size and Configuration in Your Selection Process

When selecting sanitary ball valves, valve size and configuration play crucial roles. The right size ensures that flow rates meet operational demands. For example, a study by the Fluid Control Institute indicated that incorrectly sized valves can reduce system efficiency by up to 30%. This inefficiency impacts production and affects overall system performance.

Configuration also matters. Valves come in various designs, such as two-way or three-way configurations. Each serves distinct applications. A report by the International Society of Automation highlighted that using the correct configuration could improve flow control by 25%. However, many users overlook this aspect, leading to suboptimal setups.

Even with the right size and configuration, other factors can influence performance. Materials, for instance, should match the fluid being handled. Incompatible materials can result in leaks or valve failure over time. It’s essential to consider all aspects of the valve, not just size and type, to ensure reliability and efficiency.

Maintenance and Performance: Ensuring Longevity of Your Valves

When it comes to sanitary ball valves, maintenance is key to ensuring longevity. Regular inspection can prevent unexpected failures. According to industry reports, 65% of valve issues stem from poorly maintained systems. That number can be reduced significantly with proactive measures. Simple checks for leaks, corrosion, or any signs of wear can make a difference.

Tips: Always keep an inspection log. Document any changes or concerns with your valves. This helps in tracking performance over time.

Performance optimization is crucial. Ensure that valve seals are intact. Reports suggest that seals failing can lead to about 20% efficiency loss. Regularly replace them to maintain performance. Temperature and pressure ratings should meet specific needs too. Many users overlook this vital aspect.

Tips: When in doubt, consult with an expert. A second opinion can save costly mistakes. Remember, improper fittings can lead to bigger issues. Always measure accurately before installation.

Related Posts

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

How to Choose the Right Sanitary Ball Valves for Your Applications

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

2025 Guide: How to Choose the Right Sanitary Ball Valves for Your System

-

The Ultimate Guide to Understanding and Choosing Butterfly Valves for Your Industrial Needs

-

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing