2026 Best Stainless Steel Ball Valves What to Look For?

Choosing the right stainless steel ball valves is crucial for many applications. These valves are known for their durability and efficiency. However, not all stainless steel ball valves are created equal. When making a decision, consider several key factors.

First, assess the material quality. Look for high-grade stainless steel that can withstand harsh environments. The valve design also matters. A well-designed ball valve enhances flow control and reduces the risk of leaks. Failing to choose the correct design can lead to inefficiencies.

Next, think about the size and connection type. These aspects affect installation and compatibility. Lastly, explore the manufacturer’s reputation. It’s essential to choose a trusted brand. A good brand can make a difference in performance and longevity. Balancing these factors can help you make a more informed choice.

Key Features of Stainless Steel Ball Valves to Consider

When selecting stainless steel ball valves, consider their construction. The material must withstand corrosion and high pressure. Look for valves made from high-quality stainless steel. This ensures durability and longevity. A well-made valve should also have a smooth finish. It prevents buildup and enhances operation efficiency. Taking time to check this aspect can save future maintenance costs.

Next, focus on the valve size and connection type. Different applications may require various sizes. Ensure the valve fits seamlessly into your system. Look at the connection type, such as threaded or welded. Each has its pros and cons. Selecting the wrong type can lead to leaks or failures. It’s crucial to double-check compatibility with your existing setup.

Don’t forget about the valve seat material. PTFE is common for its resilience. However, think about your specific flow conditions. Some situations might require alternative materials. Lastly, consider the valve’s operating pressure and temperature limits. They are not always clearly stated. Verify that they align with your needs to avoid unexpected issues.

2026 Best Stainless Steel Ball Valves - Key Features to Consider

| Feature | Description | Importance |

|---|---|---|

| Material Grade | Common grades include 304 and 316 stainless steel, affecting corrosion resistance. | High |

| Size Options | Available in various sizes, typically from 1/4" to 6". | Medium |

| Connection Types | Includes threaded, flanged, or welded connections for different applications. | High |

| Pressure Rating | Rated for various pressure standards, typically up to 600 psi. | High |

| Temperature Range | Operational temperature range from -20°F to 400°F depending on the valve design. | Medium |

| Actuation Type | Options include manual, electric, or pneumatic actuators for remote operation. | Medium |

| Seal Type | Common seals include PTFE or rubber, affecting leak prevention and durability. | High |

Types of Stainless Steel Used in Ball Valves and Their Advantages

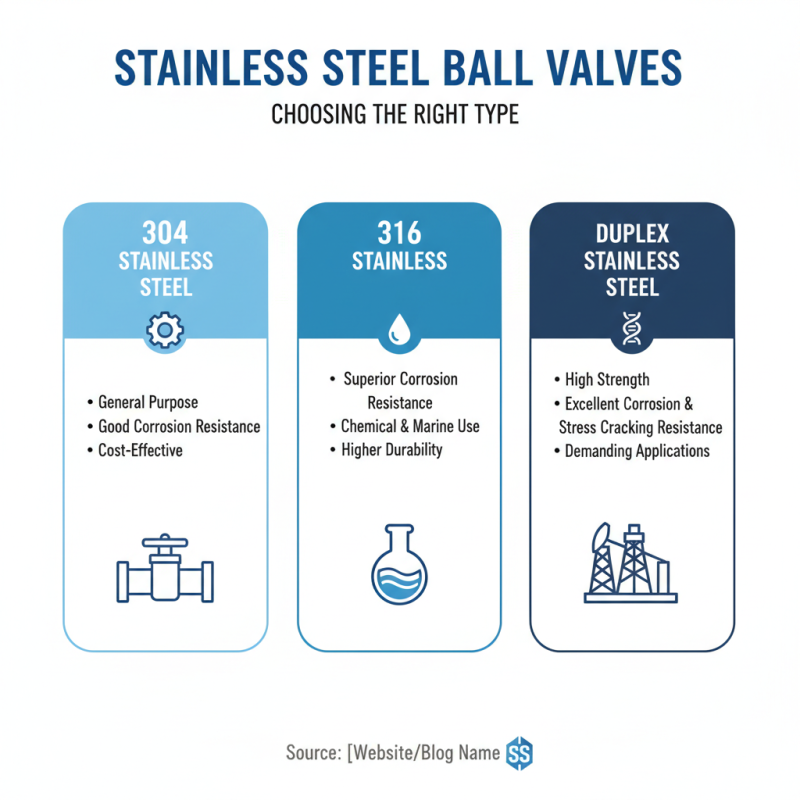

When choosing stainless steel ball valves, understanding the types of stainless steel used is crucial. There are mainly three types: 304, 316, and duplex stainless steel. Each offers unique benefits tailored to specific applications.

304 stainless steel is the most common option. It has a good balance of strength and corrosion resistance. However, it might not withstand harsh environments. In contrast, 316 stainless steel contains molybdenum, enhancing its resistance to pitting in chloride environments. This makes it ideal for marine applications or chemical processing. Reports show that 316 stainless steel valves can last 30% longer in corrosive settings compared to 304.

Duplex stainless steel is another option. It combines the best of both worlds: high strength and excellent corrosion resistance. It's particularly useful in industries like oil and gas. However, it is often more expensive and requires special handling during manufacturing. This trade-off can lead to project budgeting challenges. Understanding these differences is vital when selecting the right valve for your needs. Disregarding the material characteristics can lead to premature valve failure and expensive repairs.

Understanding Valve Sizing and Its Impact on Performance

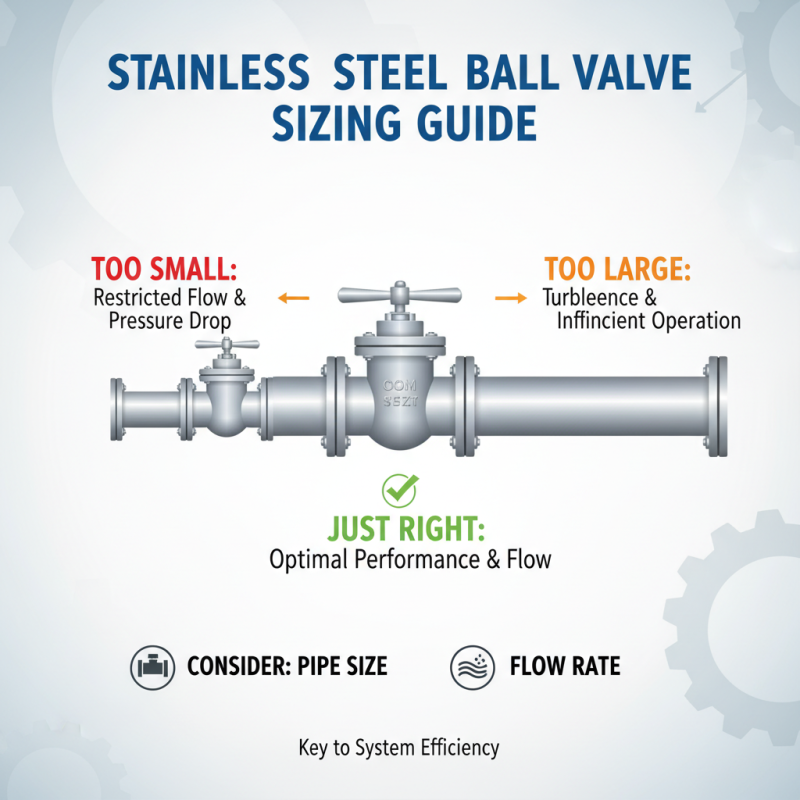

When choosing stainless steel ball valves, understanding valve sizing is crucial. The right size affects the overall performance of your system. A valve that is too small can restrict flow, causing pressure drop. Conversely, an oversized valve may lead to turbulence and inefficient operation. It's essential to consider the pipe size and the flow rate when selecting a valve.

Performance is not only about the size. The material and design of the valve also matter. Stainless steel offers corrosion resistance, which is important in many applications. However, even stainless steel valves can have weak points. For instance, the welds may be less durable than the body. Observing these details can save time and costs in the long run.

Failing to account for pressure ratings can lead to serious issues. A valve rated for lower pressure will eventually fail under high pressure. So, ensure to check the specifications carefully. This will prevent malfunction and unsafe situations. Choosing the right valve involves more than just picking a common size; it requires precision and attention to detail. Every decision impacts the system's reliability and efficiency.

Evaluating the Brand Reputation and Warranty of Ball Valves

When evaluating stainless steel ball valves, brand reputation plays a crucial role. A strong brand often signifies quality. According to industry reports, 70% of buyers prioritize brands with a proven track record. This emphasis on reputation reflects an understanding that reliable products lead to fewer failures and replacements over time.

Warranty terms are equally important. A warranty can indicate a manufacturer’s confidence in their product. Some survey data indicates that 60% of customers feel more secure purchasing from brands offering generous warranties. However, not all warranties are created equal. Some may have numerous exclusions or limited coverage periods. Potential buyers must read the fine print and assess if the warranty aligns with their needs.

In the stainless steel ball valve market, transparency is key. Brands that openly share their manufacturing processes and quality control standards often earn consumer trust. Yet, it’s not uncommon for manufacturers to be vague about these details. This gap can lead to uncertainty for buyers. Thus, while brand reputation and warranty are vital, consumers should also advocate for clarity in product information.

2026 Best Stainless Steel Ball Valves: Brand Reputation and Warranty Evaluation

Maintenance Tips for Long-lasting Stainless Steel Ball Valves

When maintaining stainless steel ball valves, consistent attention is key. Regular visual inspections can reveal wear and tear. Check for rust or corrosion. Even minor blemishes can lead to larger problems. According to a 2022 industry report, poorly maintained valves can decrease efficiency by up to 30%. This can translate into significant cost inefficiencies over time.

Proper lubrication is essential for smooth operation. Use the right type of lubricant specified for stainless steel. Over-lubrication is a common mistake. It can attract contaminants, causing blockages. A study indicated that 25% of valve failures are linked to improper lubrication practices. Ensure the seals are intact to prevent leaks.

Environmental factors also play a substantial role. Exposure to harsh chemicals can corrode components. Consider the surrounding environment when choosing locations for installation. A check on installation orientation is vital. Valves installed incorrectly may require more frequent maintenance. Being vigilant can extend the life of your valve system significantly.

Related Posts

-

Understanding the Benefits of Stainless Steel Ball Valves for Industrial Applications

-

Exploring Ball Valves Industry Trends at the 138th Canton Fair 2025 in China

-

2026 Best Ball Valves for Your Needs What to Consider?

-

How to Choose the Right Diaphragm Valves for Your Industrial Applications

-

The Future of Diaphragm Valves Set to Transform Fluid Control Technologies

-

Why Are Stainless Steel Fittings Preferred in Construction?