2026 Best Ball Valves for Your Needs What to Consider?

In the world of fluid management, ball valves play a crucial role. Industry expert Dr. Emily Carter states, "Choosing the right ball valve can make all the difference." Understanding the nuances of ball valves can help ensure optimal performance in various applications. As we approach 2026, it's essential to examine the features and materials that best suit your needs.

When selecting ball valves, consider factors like size, pressure rating, and material compatibility. These components determine the effectiveness and longevity of the valve. While many users assume all ball valves are equal, subtle differences can lead to issues. You may find that a specific application requires a unique design.

Investing time in understanding ball valves can lead to better decisions. It's not just about picking a valve off the shelf. An informed selection process can prevent costly mistakes later on. Take the time to explore your options and ask the right questions. In a rapidly evolving industry, staying updated is essential for success.

Understanding Ball Valves: Types and Applications

Ball valves are widely used in various industries. These valves offer reliability and performance. They are designed to isolate or control the flow of fluids. Understanding the types of ball valves is crucial before making a selection.

There are several types, including floating, trunnion-mounted, and segment ball valves. Floating ball valves are common for low-pressure applications. They rely on the fluid's pressure to seal properly. Trunnion-mounted valves handle higher pressures and are more stable. Segment ball valves provide unique advantages in throttling applications. Each type has specific applications and must be chosen based on your needs.

Ball valves often face challenges like wear and tear. Regular maintenance is necessary to ensure optimal performance. It's easy to overlook small issues, but these can lead to bigger problems. Evaluating your system’s requirements is key. Consider flow rate, pressure, and material compatibility in your decision-making process.

2026 Best Ball Valves for Your Needs What to Consider? - Understanding Ball Valves: Types and Applications

| Valve Type | Material | Size (inches) | Pressure Rating (psi) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Floating Ball Valve | Stainless Steel | 1 | 150 | -20 to 200 | Water, Oil |

| Trunnion Mounted Ball Valve | Carbon Steel | 2 | 300 | -10 to 400 | Gas, Oil |

| Full Port Ball Valve | Brass | 3 | 600 | -20 to 180 | Water, Air |

| Reduced Port Ball Valve | PVC | 2.5 | 150 | -20 to 140 | Chemicals, Water |

| V-Port Ball Valve | Stainless Steel | 4 | 150 | -20 to 200 | Flow Control |

Key Features to Evaluate in Ball Valves

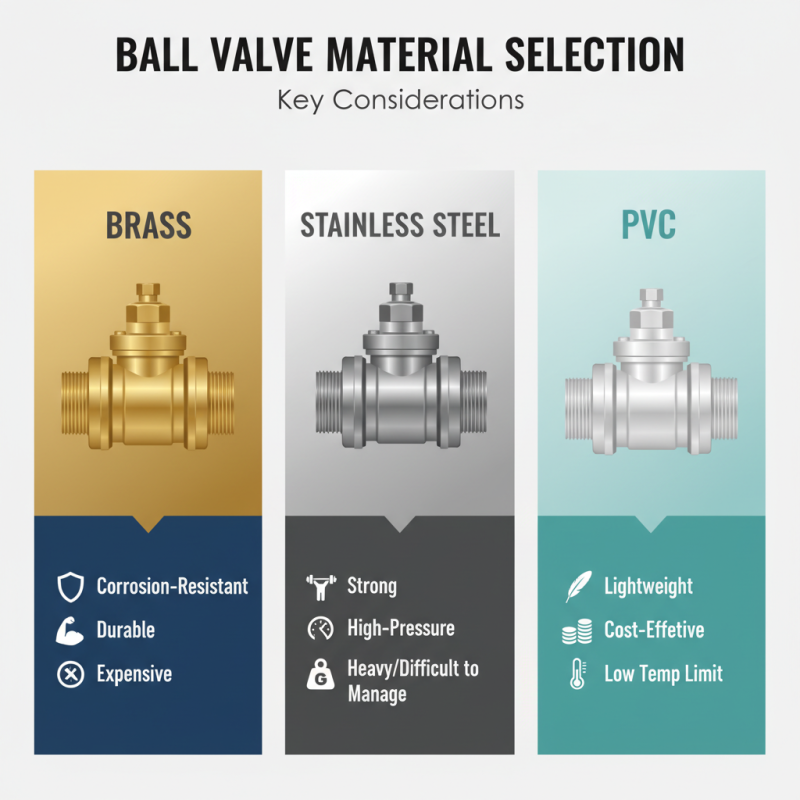

When selecting a ball valve, the features that matter most can significantly impact your project's success. One key aspect is the valve material. Common options include brass, stainless steel, and PVC. Each material has unique properties that affect durability and corrosion resistance. If your application involves harsh chemicals, consider materials that can withstand those conditions.

Another important feature is the size and pressure rating. Ensure the valve suits your pipe size and complies with pressure requirements. Inconsistent sizing can lead to leakage or failure. Additionally, look at the valve's flow characteristics. Some valves provide a full-port design for maximum flow. Others may restrict flow, impacting your system's efficiency.

You may also consider the valve's actuation method. Manual ball valves require physical operation, while automated options offer convenience. However, automation can introduce complexity. Are you ready to maintain it? Reflecting on these details can lead to a better decision. The right ball valve is not just about function, but the specific context of your needs.

2026 Best Ball Valves Features Evaluation

Material Choices for Ball Valves: Pros and Cons

When choosing ball valves, material selection is crucial. Common materials include brass, stainless steel, and PVC. Brass is corrosion-resistant and durable but can be expensive. Stainless steel is strong and ideal for high-pressure applications. However, it can be heavy and troublesome to manage. PVC is lightweight and cost-effective but may not hold up under high temperatures.

Each material has its own set of pros and cons. Consider the environment where the valve will be installed. High humidity can affect brass over time. PVC may crack in colder climates. Choose a material that matches your specific needs. Think about the fluid being controlled. Some materials can react chemically with certain liquids.

Don’t overlook the importance of long-term performance. Weighing initial costs against potential replacement expenses is vital. Think carefully before making a choice. Reflect on your specific application and the demands it brings.

Sizing and Pressure Ratings for Optimal Performance

When selecting a best ball valve, sizing and pressure ratings are critical. A valve’s size affects flow rates. Oversized valves can cause turbulence. And flow issues may arise. According to industry data, a properly sized valve can reduce pressure drops by up to 50%. This can lead to reduced energy costs, benefiting long-term operations.

Pressure ratings also play a vital role. They determine how much pressure a valve can safely handle. The American Society of Mechanical Engineers (ASME) provides guidelines for these ratings. Most industrial applications require valves with a minimum rating of 150 PSI. This rating ensures a secure performance under fluctuating conditions. Ignoring these specifications can lead to system failures and costly downtime.

Take a moment to reflect on existing setups. Are the valves sized appropriately? Are pressure ratings matched to system requirements? Sometimes, users overlook these details, which can compromise efficiency. With proper evaluation, operations can achieve optimal performance and reliability. Proper assessment can unveil hidden issues and pave the way for improvements.

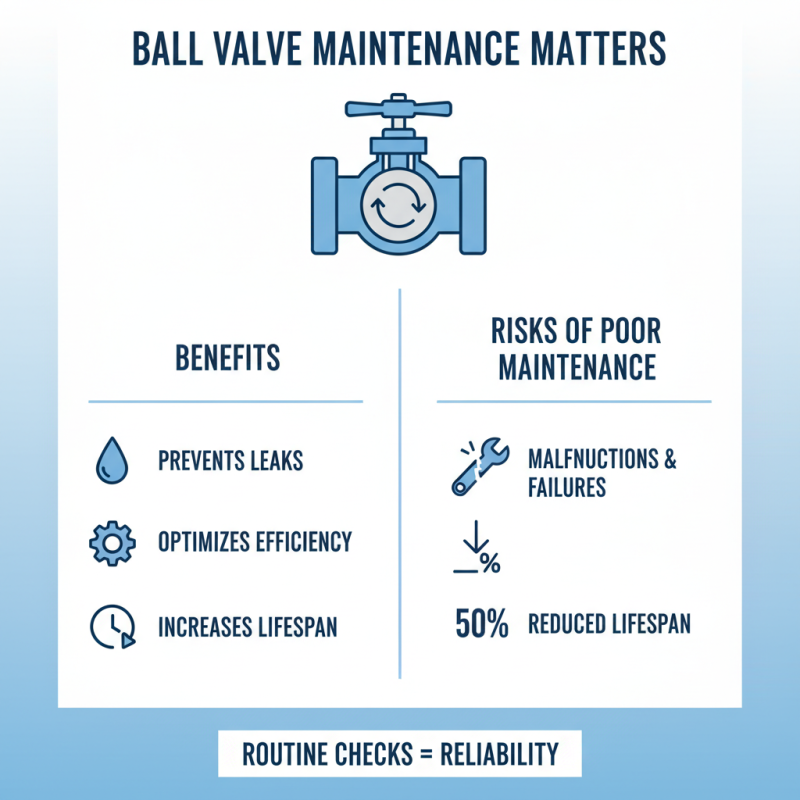

Maintenance Tips for Long-Lasting Ball Valves

Maintaining ball valves is critical for ensuring their longevity and efficiency. Regular maintenance can prevent issues like leaks and malfunctions. According to industry reports, improper maintenance can reduce the lifespan of ball valves by up to 50%. This statistic underscores the importance of routine checks and care.

One key maintenance tip involves regular inspections. Check for signs of wear or damage. Look for corrosion, particularly in environments with high humidity or exposure to various chemicals. Cleaning the valve surfaces helps maintain smooth operation. Applying lubricants at optimal intervals can also extend the valve’s life, preventing sticking or seizing.

Another consideration is the proper storage of ball valves when not in use. Keeping them in dry, clean places helps prevent rust and other forms of deterioration. Remember, even the smallest oversight can lead to larger problems down the line. Adjustments to operating conditions should also be monitored. Changes in pressure or temperature can impact valve performance. Being proactive here ensures better reliability over time.

Related Posts

-

Exploring Ball Valves Industry Trends at the 138th Canton Fair 2025 in China

-

Understanding the Benefits of Stainless Steel Ball Valves for Industrial Applications

-

The Ultimate Guide to Choosing the Right Ball Valves for Your Plumbing Projects

-

How to Choose the Best Stainless Steel Ball Valves for Your Needs

-

Top 10 Essential Brewery Fittings Every Brewer Should Consider

-

Top 2025 Trends in Sanitary Pipe Fittings: What to Expect in the Industry