2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing

In the modern manufacturing landscape, particularly within industries focused on food and pharmaceuticals, the role of sanitary tubing has become increasingly paramount. According to the 2022 BCC Research report, the global sanitary tubing market is anticipated to reach $7.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.7%. This growth underscores the critical importance of selecting the right materials and configurations in the pursuit of optimal hygiene and safety standards.

Sanitary tubing is designed to prevent contamination and ensure compliance with stringent regulatory requirements, making it an essential component in manufacturing processes. In fact, a 2021 report by Grand View Research highlighted that the food processing industry is one of the largest consumers of sanitary tubing, accounting for over 40% of the total market share. With the ongoing emphasis on health and safety, manufacturers must be vigilant in choosing tubing options that not only meet industry regulations but also enhance operational efficiency and product integrity.

As we explore the top 10 sanitary tubing choices for 2025, it is vital to consider factors such as material composition, surface finish, and design, all aimed at promoting optimal hygienic conditions. By leveraging data-driven insights and industry standards, manufacturers can make informed decisions to safeguard their operations and the quality of their products.

Top 10 Materials for Sanitary Tubing: Pros and Cons for Manufacturing

When selecting materials for sanitary tubing in manufacturing, it’s essential to weigh their pros and cons to ensure optimal hygiene and safety. Stainless steel is one of the most widely used materials due to its excellent resistance to corrosion and ease of cleaning. It can withstand high temperatures, making it suitable for applications involving steam sterilization. However, its higher cost and weight can be drawbacks for manufacturers looking for lightweight and economical options.

Another popular choice is thermoplastic elastomers (TPEs). These materials are flexible, lightweight, and easy to install. They also offer a good resistance to chemicals and UV light, making them ideal for a wide range of applications. Nevertheless, TPEs may not hold up under extreme temperatures, which could limit their use in certain manufacturing processes. Additionally, the long-term durability of TPE compared to stainless steel is often questioned, leading manufacturers to consider the specific requirements of their applications carefully.

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing

Key Factors in Selecting Sanitary Tubing for Food and Beverage Applications

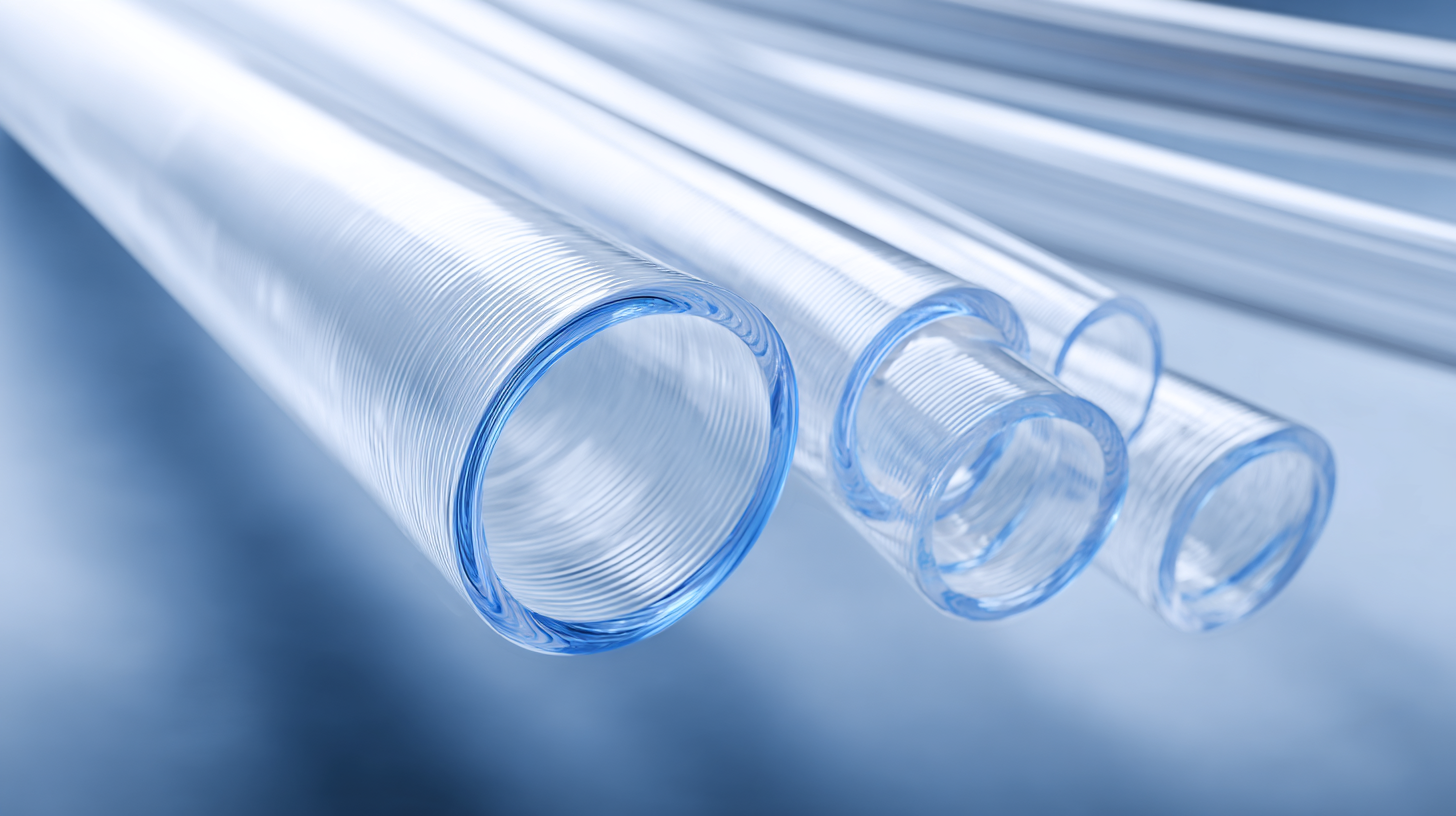

When selecting sanitary tubing for food and beverage applications, several key factors come into play to ensure optimal hygiene and safety. Firstly, the material of the tubing is crucial. Stainless steel is often preferred due to its resistance to corrosion and ability to withstand high temperatures during cleaning processes. Seamless pipes are particularly advantageous as they minimize the risk of contamination, providing a clean interior surface that enhances flow characteristics and reduces the likelihood of microbial growth.

When selecting sanitary tubing for food and beverage applications, several key factors come into play to ensure optimal hygiene and safety. Firstly, the material of the tubing is crucial. Stainless steel is often preferred due to its resistance to corrosion and ability to withstand high temperatures during cleaning processes. Seamless pipes are particularly advantageous as they minimize the risk of contamination, providing a clean interior surface that enhances flow characteristics and reduces the likelihood of microbial growth.

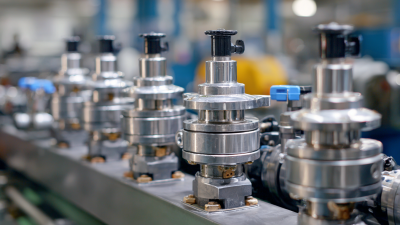

Another vital consideration is the compliance with industry standards and regulations. Utilizing compliant steam filtration systems helps mitigate risks associated with foodborne illnesses, which affect millions each year. It is essential to invest in high-quality sanitation processes and equipment to meet stringent safety specifications. Starting with clean, modern installations is generally more effective than retrofitting older systems, making careful selection of sanitary tubing a foundational step in achieving food safety and maintaining consumer trust in the manufacturing process.

Best Practices for Maintaining Hygiene in Sanitary Tubing Systems

Maintaining hygiene in sanitary tubing systems is critical for manufacturing environments, particularly in industries such as food processing, pharmaceuticals, and biotechnology. According to a recent report by the International Society for Pharmaceutical Engineering (ISPE), improper maintenance of sanitary systems can lead to contamination risks, significantly impacting product safety and quality. To mitigate these risks, it is essential to adhere to best practices that ensure the integrity and cleanliness of tubing installations.

One of the best practices includes regular inspection and cleaning of sanitary tubing systems. The Food and Drug Administration (FDA) recommends implementing a validated cleaning process, which often employs methods such as CIP (Clean-In-Place) systems. These systems, when properly designed and maintained, can effectively reduce the microbial load in the tubing, with studies showing a reduction of over 99% in contaminants when CIP protocols are followed accurately. Additionally, using the right materials—such as stainless steel or high-grade polymer—can enhance resistance to corrosion and fouling, further supporting hygiene standards.

Another fundamental aspect of maintaining hygiene is the staff training regimen. A comprehensive training program on hygiene protocols can significantly reduce the risk of contamination incidents. The same ISPE report highlights that companies with robust employee training processes experience 30% fewer contamination events compared to those that do not prioritize training. By ensuring that all personnel are knowledgeable about hygiene practices, manufacturers can establish a culture of safety and cleanliness that is vital for operational excellence and compliance.

2025 Top 10 Sanitary Tubing Choices for Optimal Hygiene and Safety in Manufacturing

| Sanitary Tubing Type | Material | Temperature Resistance (°C) | Pressure Rating (Bar) | Common Applications | Cleaning Method |

|---|---|---|---|---|---|

| Stainless Steel Tubing | 316L Stainless Steel | -196 to 400 | 10 | Food and Beverage Processing | CIP (Clean-in-Place) |

| Silicone Tubing | Silicone Rubber | -50 to 200 | 3 | Pharmaceuticals | Autoclaving |

| PTFE Tubing | PTFE (Teflon) | -150 to 260 | 5 | Chemical Handling | Steam Cleaning |

| Polypropylene Tubing | Polypropylene | -20 to 100 | 2 | Water Treatment | CIP |

| PVC Tubing | Polyvinyl Chloride | 0 to 60 | 4 | General Purpose | Chemical Washing |

| Nitrile Tubing | Nitrile Rubber | -30 to 100 | 3 | Food Transfer | Washing |

| Nylon Tubing | Nylon 11 | -40 to 80 | 6 | Compressed Air Systems | High-Pressure Cleaning |

| Polyethylene Tubing | Polyethylene | -70 to 60 | 2 | Agricultural Irrigation | Water Rinsing |

| Fiber Reinforced Tubing | Reinforced Polymer | -40 to 100 | 8 | Vacuum Systems | Chemical Cleaning |

| EPDM Tubing | Ethylene Propylene Diene Monomer | -50 to 150 | 3 | Food and Beverage | Steam Cleaning |

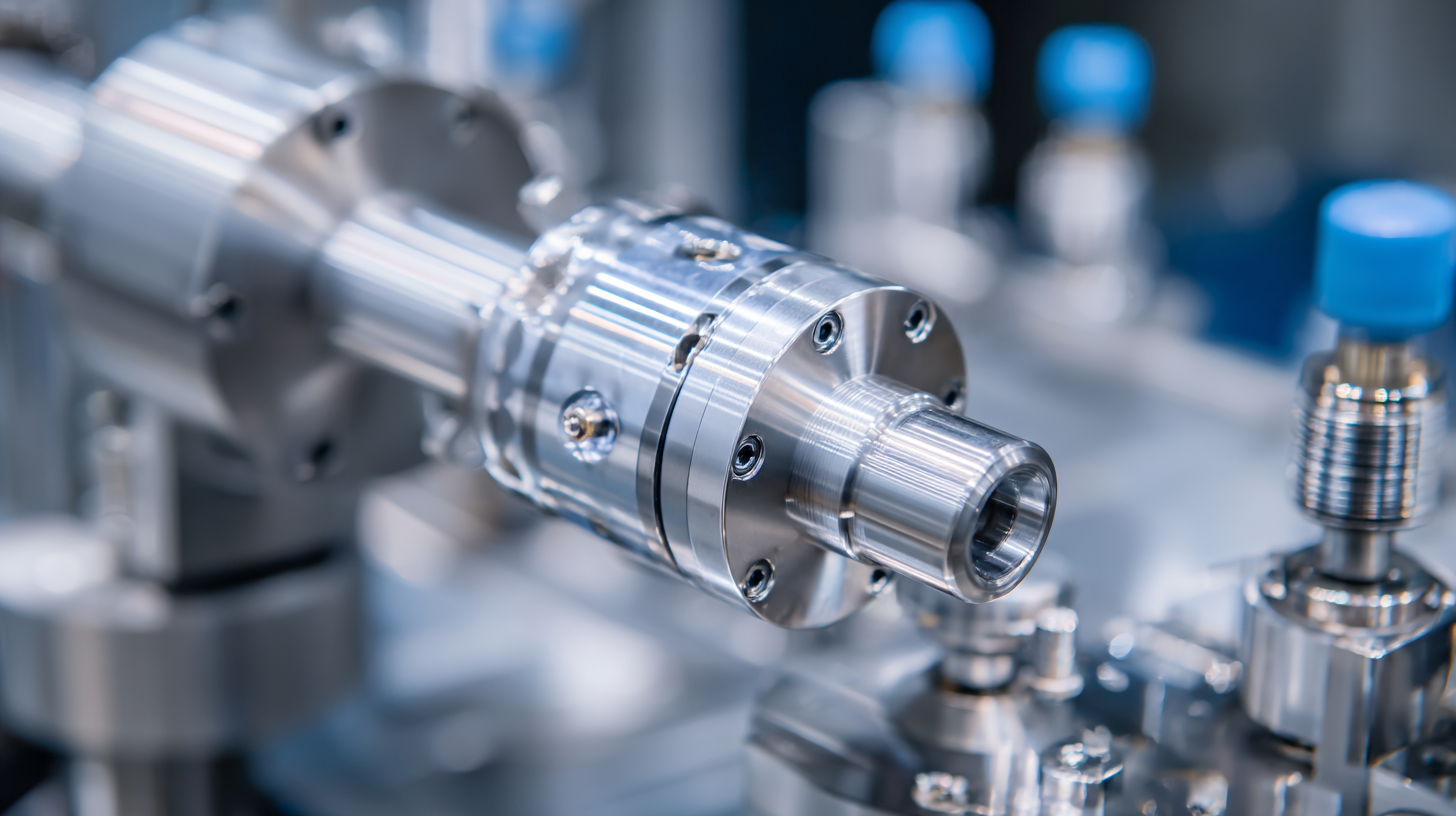

Innovative Technologies Enhancing Safety in Sanitary Tubing Manufacturing

Innovative technologies are revolutionizing the manufacturing sector, particularly in the context of sanitary tubing. As industries prioritize hygiene and safety, advancements in materials and production techniques are becoming pivotal. For instance, the stainless steel seamless pipes market is projected to showcase significant growth, driven by enhanced production technologies such as piercing and extrusion. Reports indicate that the increasing demand for sanitary applications in various end-use sectors, including food and beverage, oil, and gas, will propel this market to reach unprecedented levels.

Moreover, the food and beverage industry is experiencing transformative changes with the adoption of emerging technologies. Tools that ensure greater transparency and faster detection of contaminants are crucial for maintaining food safety standards. Reports suggest that these innovations not only improve product quality but also reduce the risk of contamination throughout the supply chain. As manufacturers leverage these advancements, they can better comply with stringent hygiene regulations, ultimately enhancing safety in sanitary tubing production and usage.

Cost-Effective Solutions for Implementing Sanitary Tubing in Your Facility

When implementing sanitary tubing in manufacturing facilities, cost-effectiveness plays a crucial role in ensuring optimal hygiene and safety. Businesses can start by evaluating their existing systems and identifying areas where sanitary tubing can replace less efficient materials. This transition not only improves safety standards but also can lead to long-term savings by reducing maintenance and cleaning costs associated with traditional tubing solutions.

Investing in high-quality, cost-effective sanitary tubing options is vital. Manufacturers should consider products that meet industry standards while also offering durability and resistance to corrosion and buildup. Collaboration with suppliers who provide comprehensive support and maintenance services can further enhance the cost-effectiveness of the investment. Adopting these solutions allows manufacturers to maintain compliance with health regulations and ensure a hygienic production environment without sacrificing budgetary constraints.

Related Posts

-

The Ultimate Guide to Choosing the Best Sanitary Tubing for Your Business Needs

-

The Ultimate Guide to Choosing the Right Sanitary Fittings for Your Facility

-

How to Select the Right Pump Valves for Your Industrial Applications

-

7 Essential Features to Look for in Sanitary Fittings

-

Essential Brewery Fittings Every Craft Brewer Must Have for Optimal Production

-

How to Choose the Right Sanitary Fittings for Your Plumbing Needs