2025 Guide: How to Choose the Right Sanitary Ball Valves for Your System

In the ever-evolving landscape of industrial processes, the significance of selecting the right sanitary ball valves cannot be overstated. As highlighted by industry expert Dr. Emily Richmond, a leading authority on fluid control systems, "The right sanitary ball valves are not just components; they are crucial to ensuring the purity and efficiency of your system." This quote underscores the importance of making informed decisions when it comes to such critical components.

Sanitary ball valves are essential in a variety of applications, particularly in industries where hygiene and cleanliness are paramount, such as food and beverage, pharmaceuticals, and biotechnology. With an array of options available, understanding the characteristics that set high-quality sanitary ball valves apart is critical. In this guide, we will explore the key factors to consider when selecting these valves, including material compatibility, design specifications, and maintenance requirements.

By arming yourself with the right knowledge, you can ensure that your system operates effectively while maintaining the highest standards of safety and sanitation. Choosing the correct sanitary ball valves not only impacts operational efficiency but also safeguards the integrity of your products and processes.

Understanding the Importance of Sanitary Ball Valves in Industrial Systems

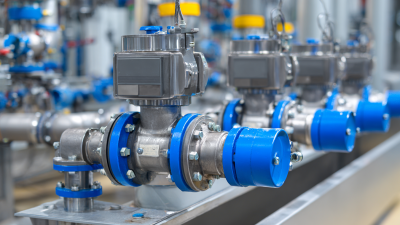

Sanitary ball valves play a crucial role in maintaining the integrity and safety of industrial systems, particularly in sectors like food and beverage, pharmaceuticals, and biotechnology. Their primary function is to ensure a tight seal, preventing leaks and contamination in processes where hygiene is paramount. These valves are designed to handle high-pressure environments while providing easy operation and maintenance. Their smooth internal surfaces eliminate crevices where bacteria could thrive, thereby ensuring compliance with stringent health and safety regulations.

When choosing sanitary ball valves for your system, consider the material from which they are constructed. Stainless steel is often preferred due to its corrosion resistance and ease of cleaning. Additionally, ensure that the valves are designed for the specific pressures and temperatures of your applications.

Tips: Always check for certifications that verify compliance with industry standards, as these documents can provide assurance that the valves will perform reliably under operational conditions. It's also wise to conduct regular maintenance checks to identify wear and tear before they lead to system failures, ensuring continuous, smooth operation.

Key Factors to Consider When Selecting Sanitary Ball Valves

When choosing the right sanitary ball valves for your system, there are several key factors to consider. The first important aspect is the material of the valve. Commonly used materials include stainless steel, which is recognized for its corrosion resistance and durability, making it suitable for a range of sanitary applications. Always ensure that the materials comply with industry standards for safety and hygiene, as this will affect the integrity of your system and its products.

Another crucial factor is the valve size and connection type. It’s essential to align the valve size with the piping system to maintain optimal flow rates and avoid pressure drops. Additionally, consider the connection type—be it tri-clamp, threaded, or welded—ensuring that it fits seamlessly with your existing infrastructure.

Tips: Before making a final decision, thoroughly assess the working conditions of your system, such as pressure and temperature ranges. Also, consider the ease of maintenance and cleanability of the valves, as this will influence the long-term efficiency and sanitation of your operations. Make sure to consult technical specifications to verify that the chosen valves will meet your operational requirements effectively.

Comparative Analysis of Materials Used in Sanitary Ball Valves

When selecting sanitary ball valves for your system, understanding the materials used is crucial. The primary materials commonly employed in these valves include stainless steel, plastic, and brass. Stainless steel, particularly 304 and 316 grades, is favored for its exceptional corrosion resistance and ability to maintain sanitary conditions. This material is ideal for applications in food and pharmaceutical industries where hygiene is paramount. Its strength and durability also make it suitable for high-temperature and high-pressure environments.

Plastic materials, such as PVC and PP, are often chosen for their lightweight properties and resistance to chemical corrosion. These valves are generally more affordable and can be beneficial in settings where the operating temperatures and pressures are lower. However, it is essential to assess the compatibility of these plastics with the specific fluids being transported, as certain chemicals can degrade them over time. Brass, while less common in sanitary applications, may be used for certain industrial contexts due to its mechanical strength and ease of manufacturing, though its susceptibility to corrosion makes it less desirable for stringent sanitary requirements.

Ultimately, the choice of material will significantly impact the performance and longevity of sanitary ball valves, and careful consideration of the operational environment and fluid composition is essential for optimal system functionality.

2025 Guide: How to Choose the Right Sanitary Ball Valves for Your System - Comparative Analysis of Materials Used in Sanitary Ball Valves

| Material | Corrosion Resistance | Temperature Range | Pressure Rating | Applications |

|---|---|---|---|---|

| 316 Stainless Steel | Excellent | -100°F to 800°F | 150 PSI | Food Processing, Pharmaceuticals |

| CPVC | Good | 32°F to 200°F | 60 PSI | Water Treatment, HVAC |

| PTFE | Excellent | -100°F to 500°F | 100 PSI | Chemical Processing, Sterile Applications |

| Brass | Fair | -40°F to 350°F | 200 PSI | General Plumbing, HVAC |

| Glass-filled Nylon | Good | -40°F to 140°F | 50 PSI | Food Processing, Water Distribution |

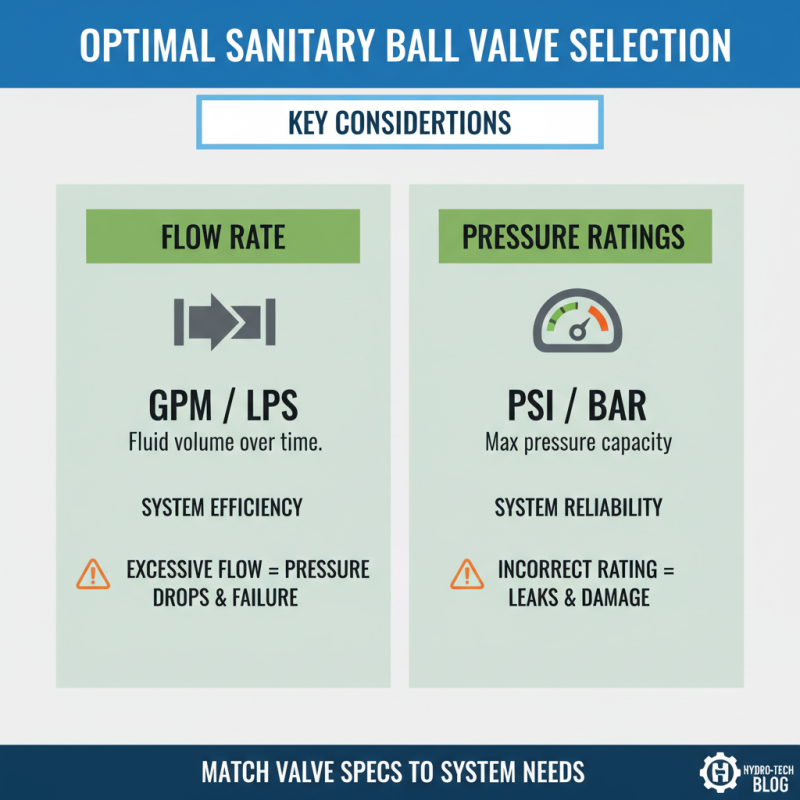

Flow Rate and Pressure Ratings: Ensuring Optimal Performance

When selecting sanitary ball valves for your system, understanding flow rate and pressure ratings is crucial for ensuring optimal performance. The flow rate, typically measured in gallons per minute (GPM) or liters per second (LPS), indicates how much fluid can pass through the valve at a given time. This measurement directly affects system efficiency; if the flow rate exceeds the valve's capacity, it can lead to pressure drops, cavitation, and even system failure. Therefore, it's essential to match the valve’s flow rating with the specific requirements of your application to maintain smooth operations.

Pressure ratings are equally important when choosing sanitary ball valves. They indicate the maximum pressure the valve can safely handle without failing. This factor is especially critical in systems subject to high-pressure fluctuations. It's vital to consider both the normal operating pressure and any potential spikes that might occur. A valve rated for higher pressures than your system's requirements provides a safety buffer, reducing the risk of leaks or catastrophic failure. By carefully evaluating both flow rates and pressure ratings, you can ensure that your chosen sanitary ball valves deliver reliable performance and longevity within your system.

Industry Standards and Certifications for Sanitary Ball Valves

When selecting sanitary ball valves for your system, understanding the relevant industry standards and certifications is crucial for ensuring quality, safety, and compliance. Key standards, such as those established by the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), provide guidelines for the design and manufacturing processes of these valves. Compliance with these standards assures users of the reliability and integrity of the valves, particularly in industries such as food and beverage, pharmaceuticals, and biotechnology.

Additionally, certifications such as 3-A Sanitary Standards and the FDA's guidelines play a significant role in validating that sanitary ball valves meet stringent hygiene and safety requirements. These certifications ensure that the materials used in the construction of the valves are non-toxic and suitable for contact with consumable products. Thoroughly evaluating whether a valve is certified can help in mitigating risks associated with contamination or product failure, thereby safeguarding both the manufacturer's reputation and consumer health.

Related Posts

-

7 Best Sanitary Valves to Enhance Your Industrial Efficiency and Compliance

-

7 Reasons Why Sanitary Valves Are Essential for Food and Beverage Industry

-

How to Choose the Best Sanitary Ball Valves for Your Industrial Needs

-

Revolutionizing Process Efficiency with Smart Sanitary Valves in Modern Industries

-

Why You Need a Comprehensive Sanitary Fittings Catalog for Your Projects

-

Why Sanitary Connectors Are Essential for Maintaining Hygiene in Food Production